22

Where it is necessary to use more than the average number of

pipe fittings i.e. elbows, tees, and valves in gas supply line, use

a pipe larger than specified to compensate for increased

pressure drop.

Gas control trains are unique for each Genesis II unit. Stages one,

two and three run sequentially left to right on the smaller units (GB/

GW 1000 -1500) while stage one is located in different positions on

the larger units. Gas manifold diagrams are depicted in Figure 14.

WIRING CONNECTIONS

ALL ELECTRICAL WORK MUST BE INSTALLED IN

ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE,

ANSI/NFPA 70 OR CSA-C22.1 CURRENT EDITION AND MUST

CONFORM TO LOCAL REGULATIONS.

AN ELECTRICAL GROUND IS REQUIRED TO REDUCE RISK OF

ELECTRIC SHOCK OR POSSIBLE ELECTROCUTION.

Make the

ground connection to the wire provided in the electrical supply

junction box on the boiler.

Grounding and all wiring connected to this boiler must conform to

the local code authority having jurisdiction or, in the absence of such

requirements, with the

National Electrical Code, ANSI/NFPA 70 or

CSA-C22.1 current edition.

The Central Control Board and Flame Control Boards that make

up the control system are micro-processor based which make

them vulnerable to voltage and amperage fluctuations in the

power supply. Refer to Connection and Schematic Diagrams.

See Figures 15 and 16.

IF ANY OF THE ORIGINAL WIRE, AS SUPPLIED WITH THE

APPLIANCE, MUST BE REPLACED, IT MUST BE REPLACED WITH

TYPE 105°C WIRE OR ITS EQUIVALENT.

The Genesis Hot Water Supply Boiler must be connected to a single

phase dedicated and isolated line source: 120 volts, 60Hz, and 30 Amps.

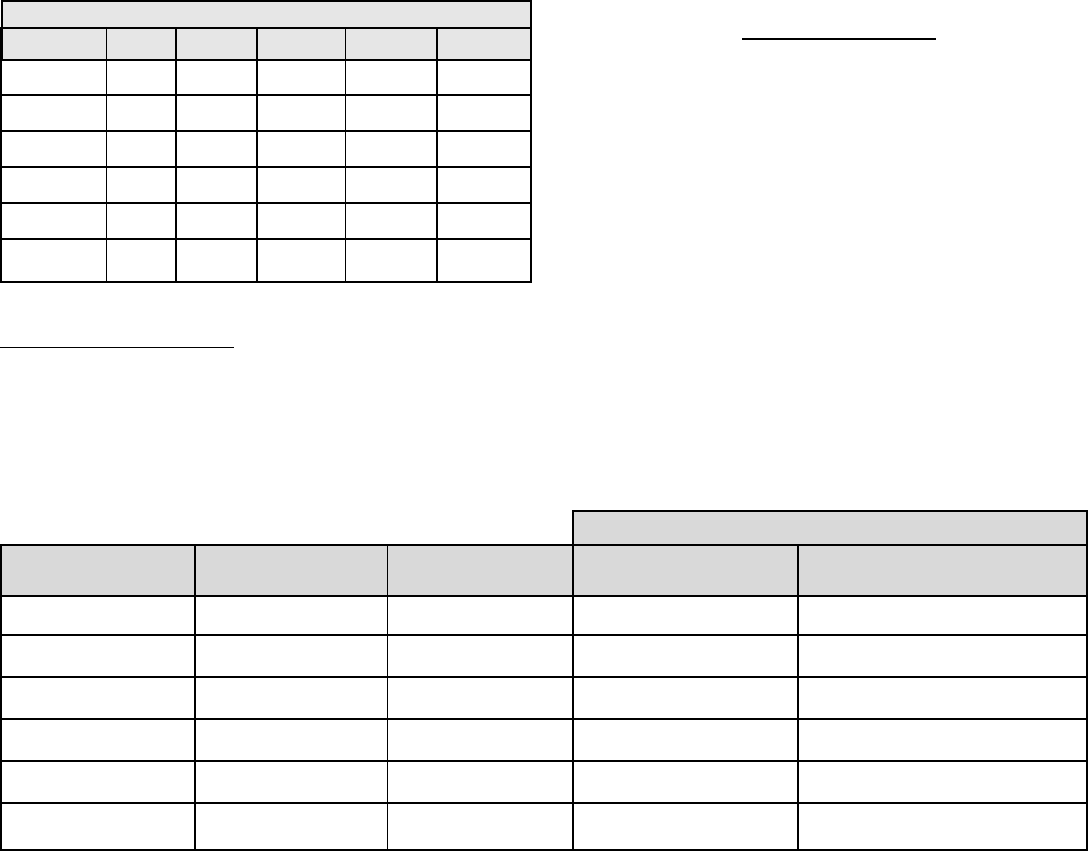

TABLE 18. Orifice Size for Natural and Propane (LP) Gases (U.S. and Canada Installations, for high altitude up to

4,500 ft. (1,372 m).

Drill Size

Input Rating Number of

Model BTU/HR Burners Natural (4 Holes) Propane (3 Holes)

G(B,W) 1000 990,000 10 0.111" 0.075"

G(B,W) 1300 1,300,000 13 0.111" 0.075"

G(B,W) 1500 1,500,000 15 0.111" 0.075"

G(B,W) 1850 1,850,000 19 0.111" 0.075"

G(B,W) 2100 2,100,000 21 0.111" 0.075"

G(B,W) 2500 2,490,000 25 0.111" 0.075"

Gas Pipe sizing may be larger than heater connections on

installations where a significant run of piping is required. To prevent

damage, care must be taken not to apply too much torque when

attaching gas supply pipe to gas inlet.

Fittings and unions in the gas line must be metal to metal type.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

1. CORRECT GAS - Make sure gas on which the boiler will operate

is the same as that specified on the rating plate. Do not install

the boiler if equipped with a different type of gas. Consult your

gas supplier.

2A. SIZING GAS SUPPLY LINE (For single boiler installations). See

Table 17.

2B.SIZING GAS SUPPLY LINE (For multiple installations of two

or more boilers). See Tables 15 (Natural Gas) and 16

(Propane Gas).

TABLE 17. SINGLE UNIT INSTALLATION, SUGGESTED

PIPE SIZE

DISTANCE FROM METER

BTU INPUT 0-50' 51-100' 101-200' 201-300' 301-500'

990,000 2" 2" 2 1/2" 2 1/2" 2 1/2"

1,300,000 2" 2 1/2" 2 1/2" 3" 3"

1,500,000 2" 2 1/2" 3" 3" 3 1/2"

1,850,000 2 1/2" 2 1/2" 3" 3" 3 1/2"

2,100,000 2 1/2" 3" 3" 3 1/2" 4"

2,500,000 2 1/2" 3" 4" 4" 4 1/2"

Use Tables 15 or 16, which are taken from ANSI booklet Z223.1,

NATIONAL FUEL GAS CODE, or CAN/CSA-B149.1 (current edition)

to size iron pipe or equivalent gas supply line.