17

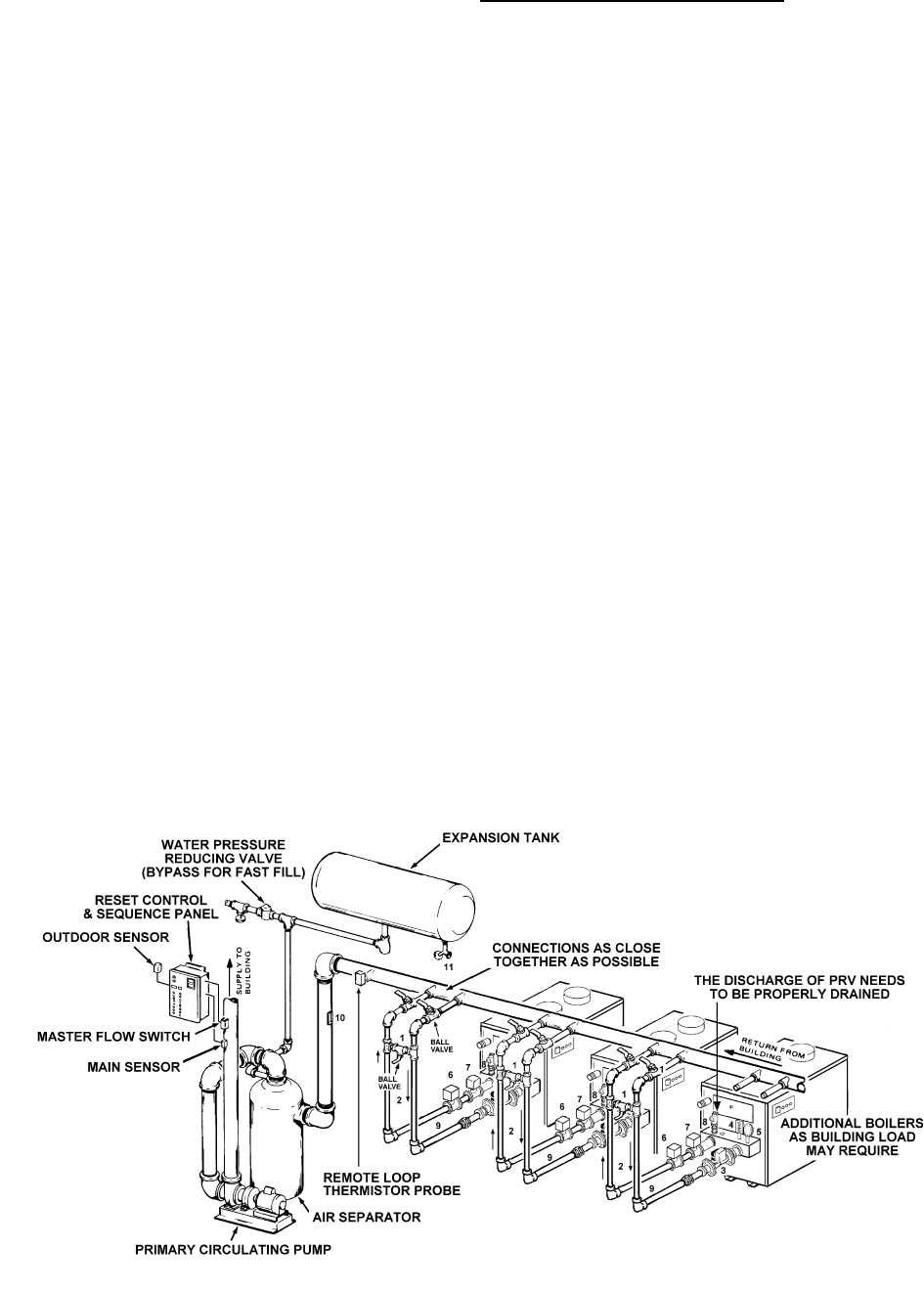

Large systems with multiple boilers should include main water

temperature controls (with or without outdoor reset) to sequence the

boiler on and off, in relation to the load on the system.

24 VAC System Controller (Optional)

GB models require a field supplied 24VAC operating control to be

installed in the system such as: loop thermostat, indoor/outdoor reset

control, sequencing panel, or energy management system. The

connection for such devices is located in the 24 VAC junction box at

the rear of the unit. A 24 VAC thermostat/aquastat can only be used as

an "On/Off" switch for the unit. The actual controlling of the staging will

be through either the inlet or tank probe.

INTERNAL CONTAMINANTS

The system must be internally cleaned and flushed after a new or

replacement unit has been installed to remove contaminants that

may have accumulated during installation. This is doubly important

when a replacement unit is installed into an existing system where

Stop Leak or other boiler additives have been used.

All systems should be completely flushed with a grease removing

solution to assure trouble-free operation. Pipe joint compounds, soldering

paste, grease on tubing and pipe all tend to contaminate a system.

Failure to clean and flush the system can cause solids to form on

the inside of the heat exchanger, can produce acid concentrations

that become corrosive, can allow excessive amounts of air or other

gases to form which could block circulation, foul system

accessories and damage circulator seals and impellers.

It is recommended that after installation, the boiler and system

when filled should include the proper percentage of cleaning solution

This bypass may also be used with multiple boilers manifolded for

reverse-return flow. The system bypass would be installed from boiler

outlet to suction side of pump.

The boiler piping system of a hot water heating boiler connected to

heating coils located in air handling units where they may be

exposed to circulating refrigerated air, must be equipped with flow

control valves or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle. It is highly recommended

that the piping be insulated.

SPACE HEATING APPLICATIONS

Controlling of these systems is decided mainly by the type of

building system controlling that is desired. A single boiler installation

might be controlled directly from space temperature thermostat(s).

Multiple boiler installations are more effective when the boilers are

sequenced in and out of operation by some form of main water

temperature controller. With one or two boilers, individual control

settings at progressive temperature may be used. For more than

two boilers, electronic sequencing controlling is recommended.

Individual controls, or the separate stages of a step controller, should

start the boiler loop circulator and fire the boiler. Some large

installations may require the firing of more than one boiler per stage.

The system or primary circulator may or may not be controlled

by the boiler sequencer. When this pump is operated through

the first switch of any type of step controller, care should be

taken to determine if a motor starter is needed due to

insufficient switch capacity.

Multiple boiler installations are especially adapted to the use of

outdoor reset for main water temperatures. This feature is not

mandatory but offers smooth, efficient operation of a modern

system.

Normal use of flow control valves is required to prevent cross

circulation of zones as with any multiple pump system.

Figure 10. Single or Multiple Boiler Installation Diagram