19

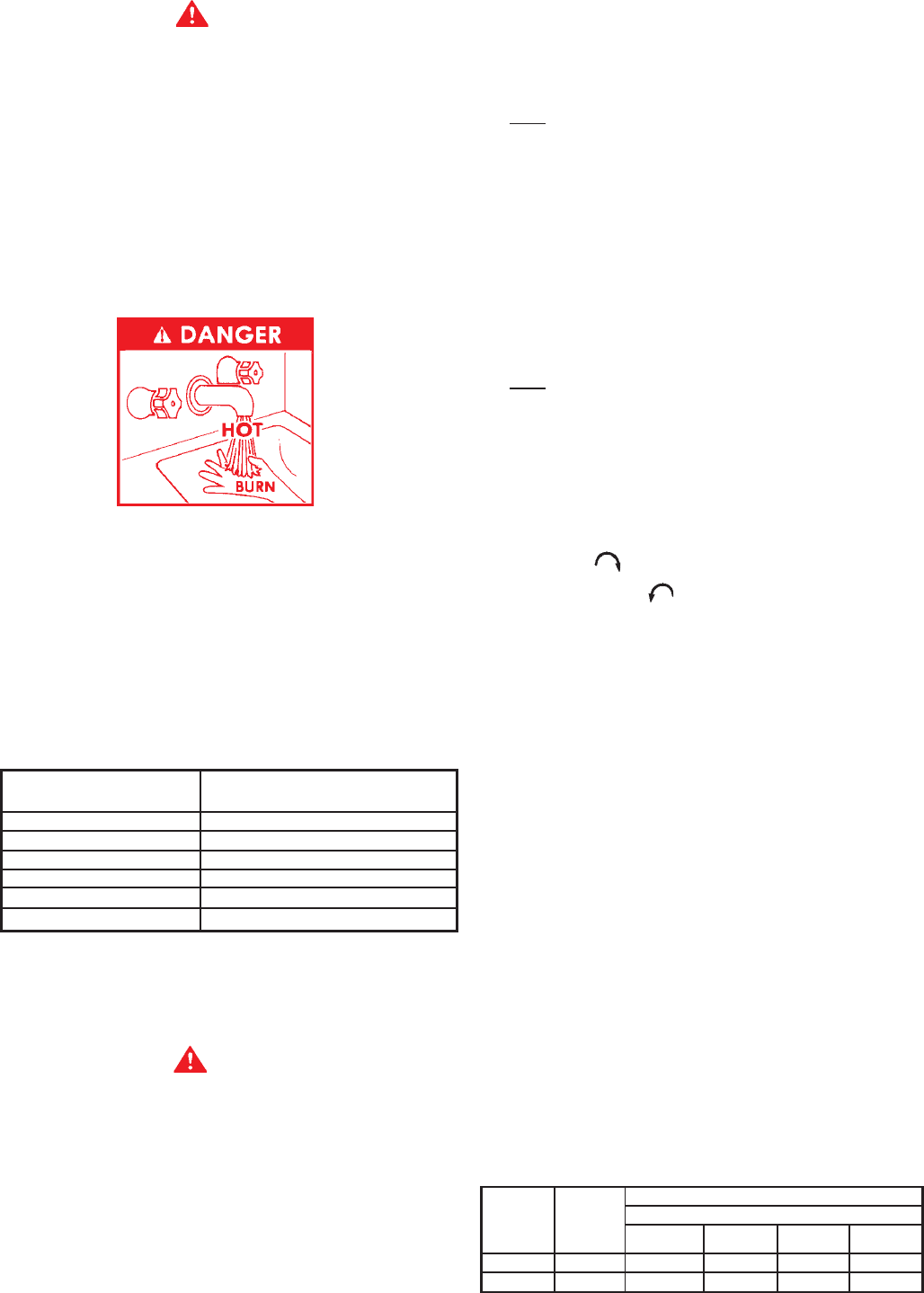

DANGER

HOT WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD

BURNS RESULTING IN SERIOUS PERSONAL INJURY AND/

OR DEATH. THE TEMPERATURE AT WHICH INJURY OCCURS

VARIES WITH THE PERSON’S AGE AND TIME OF EXPOSURE.

THE SLOWER RESPONSE TIME OF CHILDREN, AGED OR

DISABLED PERSONS INCREASES THE HAZARDS TO THEM.

NEVER ALLOW SMALL CHILDREN TO USE A HOT WATER

TAP, OR TO DRAW THEIR OWN BATH WATER. NEVER LEAVE

A CHILD OR DISABLED PERSON UNATTENDED IN A BATHTUB

OR SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA

WHERE THE GENERAL PUBLIC DOES NOT HAVE ACCESS

TO SET TEMPERATURES.

It is recommended in domestic hot water applications that lower

water temperature be used to avoid the risk of scalding. It is

further recommended, in all cases, that the water temperature be

set for the lowest temperature which satisfies the user’s hot water

needs. This will also provide the most energy efficient operation

of the boiler and minimize scale formation in the heat exchanger,

thus prolonging the life of the boiler.

SETTING THE WATER HEATER TEMPERATURE AT 120°F

(49°C) WILL REDUCE THE RISK OF SCALDS. Some states

require settings at specific lower temperatures. The table below

shows the approximate time-to-burn relationship for normal adult

skin.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

Over 170°F (77°C) Nearly instantaneous

160°F (71°C) About 1/2 seconds

150°F (66°C) About 1-1/2 seconds

140°F (60°) Less than 5 seconds

130°F (54°) About 30 seconds

120°F (49°C) or less More than 5 minutes

Table 7

USE ANTI-SCALD VALVE(S) in the hot water system to reduce

the risks of scalding at points of use such as lavatories, sinks and

bathing facilities.

CAUTION

IN THE EVENT OF ELECTRIC POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THE HEATER.

CHECKING AND ADJUSTING THE INPUT

The maximum inlet gas pressure must not exceed the value

specified by the manufacturer (10.5" W.C. - natural gas,

13.0" W.C. - propane gas). The minimum value listed on the

Rating Plate is for the purposes of input adjustment.

1. Turn the gas valve control knob to “OFF”, (See page 18).

2. Attach a pressure gauge or a manometer to the outlet pressure

tap, figure 14 and refer to table 3 for correct manifold pressure.

3. Fire the heater by turning the gas valve control knob to “ON”.

4. Use this formula to “clock” the meter. Be sure that other gas

consuming appliances are not operating during this interval.

3600

T x H = Btuh

T = Time (in seconds) to burn one cubic foot of gas.

H = Heating value of gas (in Btu’s per cubic foot of gas).

Btuh = Actual heater input (in Btuh).

EXAMPLE: (Using HW-120M heater)

T = 31.5 seconds/ft

3

H = 1050 Btu/ft

3

Btuh = ?

3600 x 1050 = 120,000 (compare with the ratings in

31.5 Table 5).

Should it be necessary to adjust the gas pressure to the burners

to obtain the full input rate, the steps below should be followed.

5. Remove the regulator adjustment sealing cap, fig. 14, and

adjust the pressure by turning the adjusting screw with a

screwdriver.

• Clockwise to increase gas pressure and input rate.

• Counterclockwise

to decrease gas pressure and input

rate.

DO NOT turn the adjusting screw in past the point of little or no

manifold pressure change or fully bottom the adjusting screw.

6. “Clock” the meter as in step 4 above.

7. Repeat steps 5 and 6 until the specified input rate is achieved.

8. Turn the gas valve control knob to “OFF”. Replace the regulator

adjustment sealing cap and remove the pressure gauge or

manometer from the outlet pressure tap. Using an allen

wrench, replace the set screw in the outlet pressure tap.

9. Turn the gas valve control knob to “ON”.

If gas pressure regulator cannot be equipped to give the full input

rating with sufficient gas pressure at the valve, re-orifice the main

burners.

IMPORTANT

UNDER NO CIRCUMSTANCES SHOULD THE GAS INPUT

EXCEED THE INPUT SHOWN IN TABLE 2. OVERFIRING

COULD RESULT IN DAMAGE OR SOOTING OF THE HEATER.

When the heater is operating at full capacity, or full gas input, it

should consume 1 cu. ft. of gas in approximately the amount of

time indicated in table 8.

TABLE 8 — TIME REQUIRED TO CONSUME 1 CUBIC FT. OF GAS

(Heater operating at full input or full capacity.

Does not apply to high altitude installations.)

Heating Total Time Required (Seconds)

Value MODEL

Type of (Btu/

Gas Cu. Ft.) HW-120M HW-160M HW-200M HW-225M

Natural 1050 31.5 23.6 19.0 16.8

Propane 2500 78.3 56.3 45.2 - - -