8

the authority having jurisdiction, must be provided with a low water

cutoff device either as a part of the boiler or at the time of boiler

installation.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE EQUIPMENT ROOM

WHERE THE BOILER IS INSTALLED EVER BE UNDER NEGATIVE

PRESSURE. PARTICULAR CARE MUST BE TAKEN WHEN

EXHAUST FANS, COMPRESSORS, AIR HANDLING EQUIPMENT,

ETC., MAY INTERFERE WITH THE COMBUSTION AND

VENTILATION AIR SUPPLIES OF THIS BOILER.

CHEMICAL VAPOR CORROSION

Heat exchanger corrosion and component failure can be caused

by the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, and process chemicals are typical compounds

which are corrosive. These materials are corrosive at very low

concentration levels with little or no odor to reveal their presence.

Products of this sort should not be stored near the boiler. Also, air

which is brought in contact with the boiler should not contain any of

these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. Failure to observe this

requirement will void the warranty.

INSTALLATION CLEARANCES

Sufficient area should be provided at the front and sides of the

unit for proper servicing. For ease of service, minimum

clearances of 24" (61.0 cm) in the front and 18" (46.0 cm) on

the sides are recommended. It is important that the minimum

clearances be observed to allow service to the control box and

other controls. Observing proper clearances will allow service to

be performed without movement or removal of the boiler from its

installed location. Failure to observe minimum clearances may

require removal of the boiler in order to service such items as the

heat exchanger and burners. In a utility room installation, the

door shall be wide enough to allow the boiler to enter or to permit

the replacement of another appliance.

Two inch (5.1 cm) clearance is allowable from combustible

construction to hot water pipes. Sufficient clearance should be

provided at one end of the boiler to permit access to heat exchanger

tubes for cleaning.

Access to control box items such as the Central Control Board,

Flame Control Boards, Power Distribution Board and wiring

harnesses is provided through a panel on the left side of the unit.

A minimum service clearance of 18" (46.0 cm) is required.

These boilers are approved for installation on noncombustible

flooring in an alcove with minimum clearance to combustibles of:

3 inches (7.6 cm) Right Side, and Back; 6 inches (15.2 cm) Top;

Front, Alcove; 12 inches (30.5 cm) Left Side; and 6 inches

(15.2 cm) surrounding the Vent.

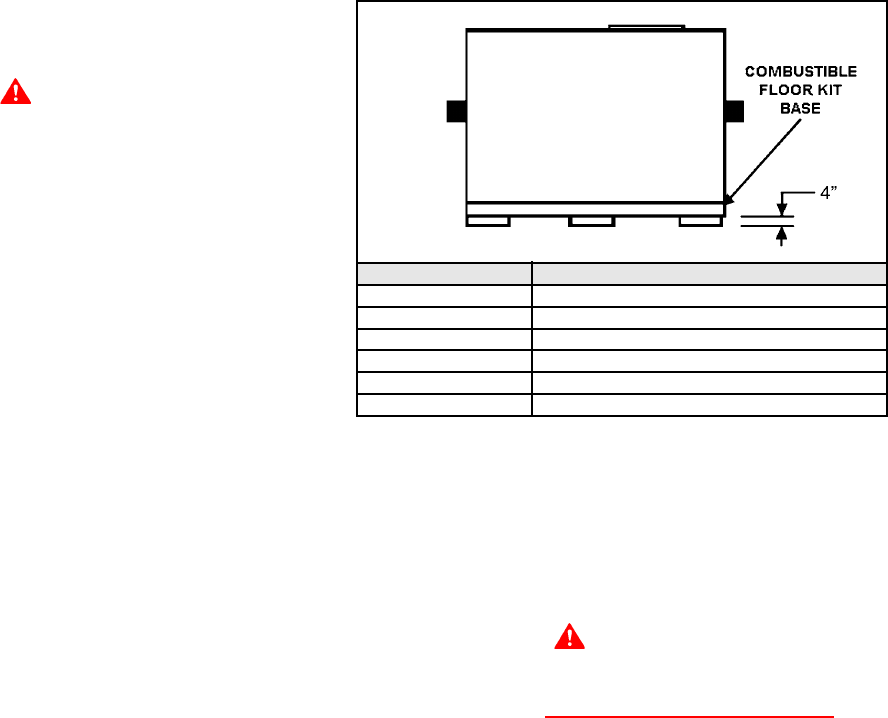

For installation on combustible flooring use the Combustible Floor

Kit. The combustible floor kit base adds 4" (10.1 cm) to the overall

height of the boiler. See Figure 3.

MODEL COMBUSTIBLE BASE KIT NUMBER

G(B,W) - 1000 211093

G(B,W) - 1300 211093-1

G(B,W) - 1500 211093-2

G(B,W) - 1850 211093-3

G(B,W) - 2100 211093-4

G(B,W) - 2500 211093-5

Figure 3. Boiler on Combustible Floor Base and Kit Numbers.

LEVELLING

Each unit must be checked after installation to be certain that it is level.

AIR REQUIREMENTS

WARNING

FOR SAFE OPERATION, AN AMPLE SUPPLY OF AIR MUST BE

PROVIDED FOR PROPER COMBUSTION AND VENTILATION IN

ACCORDANCE WITH THE NATIONAL FUEL GAS CODE, ANSI

Z223.1 OR CAN/CSA-B149.1 CURRENT EDITION OR APPLICABLE

PROVISIONS OF THE LOCAL BUILDING CODES. AN

INSUFFICIENT SUPPLY OF AIR MAY RESULT IN A YELLOW,

LUMINOUS BURNER FLAME, CARBONING OR SOOTING OF THE

FINNED HEAT EXCHANGER, OR CREATE A RISK OF

ASPHYXIATION. DO NOT OBSTRUCT THE FLOW OF

COMBUSTION AND VENTILATION AIR.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation, must be obtained from outdoors or spaces freely

communicating with the outdoors. The installation instructions for

confined spaces in tightly constructed buildings must be followed

to ensure adequate air supply.

CONFINED SPACE

(a) U. S. INSTALLATIONS

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE

WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE WITHIN

12 INCHES OF THE ENCLOSURE BOTTOM. Each opening shall

have a free area of at least one square inch per 1000 Btu/hr

(22 cm

2

/k W) of the total input of all appliances in the enclosure.