page

2

Inlet

LHS

RHS

INPUT WATER SUPPLY

Utilize liquids free from impurities (such as sand or other solid particles

which will affect the efficiency of the valves, the piston and the packings).

For this reason it is advisable to fit a filter on the suction hose, with a large

filtering surface and low load loss. Replace the filter as soon as it becomes

clogged up, to avoid noisy operation and pulsations which can damage the

mechanical parts of the pump. If the pump draws from a tank place the filter

at the entrance of the same.

NB: Maximum temperature of pumped liquid is 60°C (140°F),

maximum forced suction (measured at the pump) is

10 bar (145

PSI).

BEFORE STARTING UP

1. The pump is supplied complete with oil, so the first thing to do is remove

the red cap utilized for transportation, and insert the dipstick which is

supplied with the pump.

2. Check that oil is at the correct level, by means of the oil level window

topping up if necessary using oil type indicated in chart 1.1 page 8.

3. Make sure that inlet water flow is sufficient-at least the same value as the

pump flow and that it comes out without air bubbles.

4. Prime the pump with the outlet completely open.

5. Then start up the motor, if using a gas engine bring the RPM 's up to pre-

set level.

Fig.4b- Check the suction filter

periodically.

INSTALLATION

The pump must be installed horizontally, blocked in a stable manner, by

means of the coupling flanges suitable for the type of motor/engine with

which the pump will be driven. If pulley drive is used, you must have a

protection guard.

.The pumps can rotate either clockwise or anticlockwise.

Suction and outlet piping can be attached either to the left hand side or right

hand side of the pump.

The suction hose must:

- be of a diameter equal to from 1 to 1.5 times the suction part of the pump,

- set up in such a way as to avoid the forming of air pockets,

- be as short as possible and hermetically attached to the pump to avoid

sucking air.

Below please find an example of a correct installation:

Fig.5b- Replace the

RED cap with the

dipstick supplied

with the pump.

Filter mod.FAS

COD.3000, max 20L/min

38 MESH

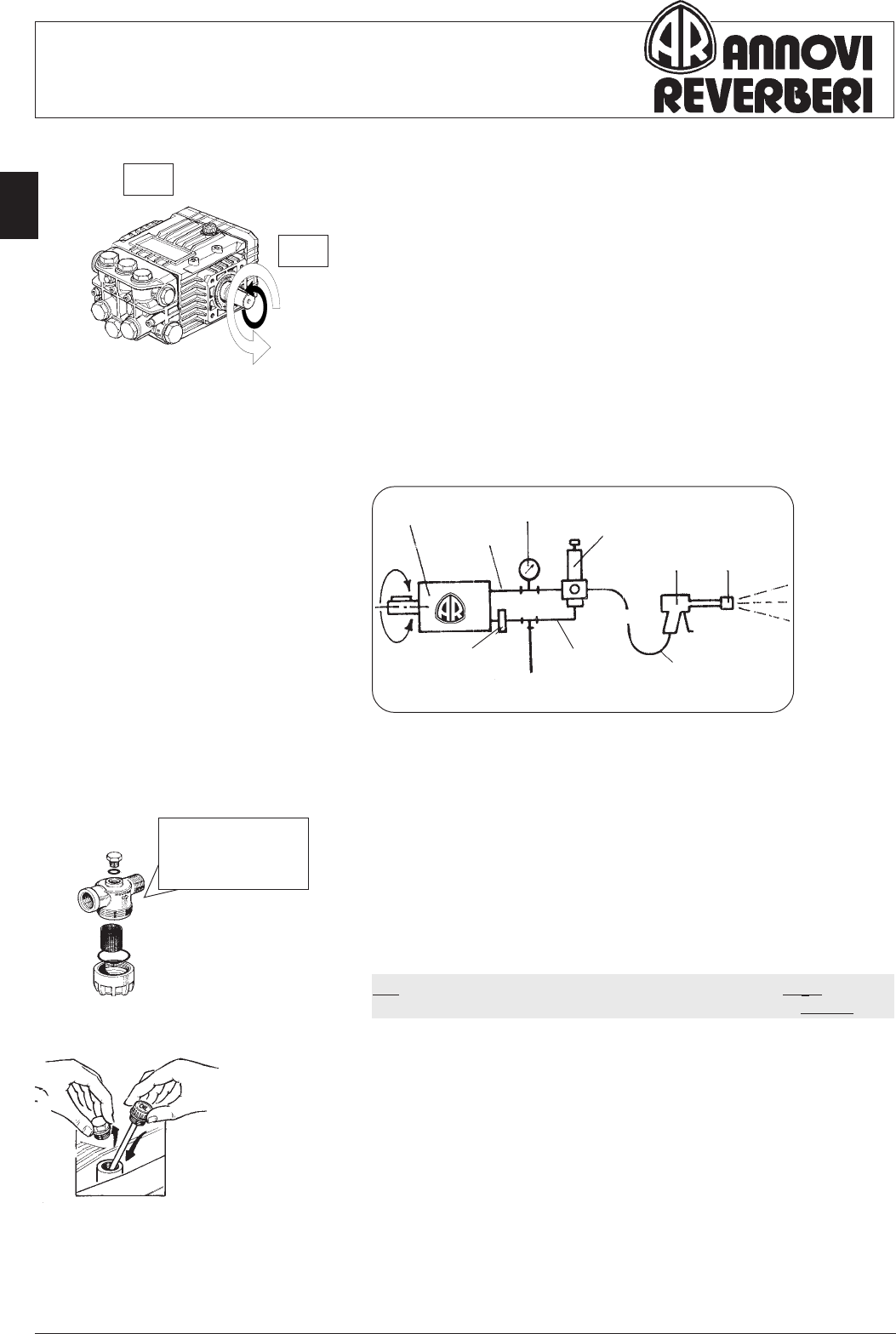

Fig.2b- Installation schematic with pressure regulating valve

OUTOUT

OUTOUT

OUT

Pump

Outlet

MINIMATIC / ZEROMATIC 83

GYMATIC / COMBISET

Gun Nozzle

By-pass

⇑

Filter

ININ

ININ

IN

O

➦

Outlet

Fig.1b- The pump can rotate either in

clockwise or anticlockwise direction.

Pressure

gauge

High pressure

hose

Inlet