TWE-SVX03C-EN 13

Installation

Note: Important! When air handler

is installed in the vertical

position and close proximity

trapping of condensate is

required, use of a subbase

accessory to raise the air

handler for clearance of the

drain trap is recommended.

See Figure 6 for a typical

drain trap assembly

.

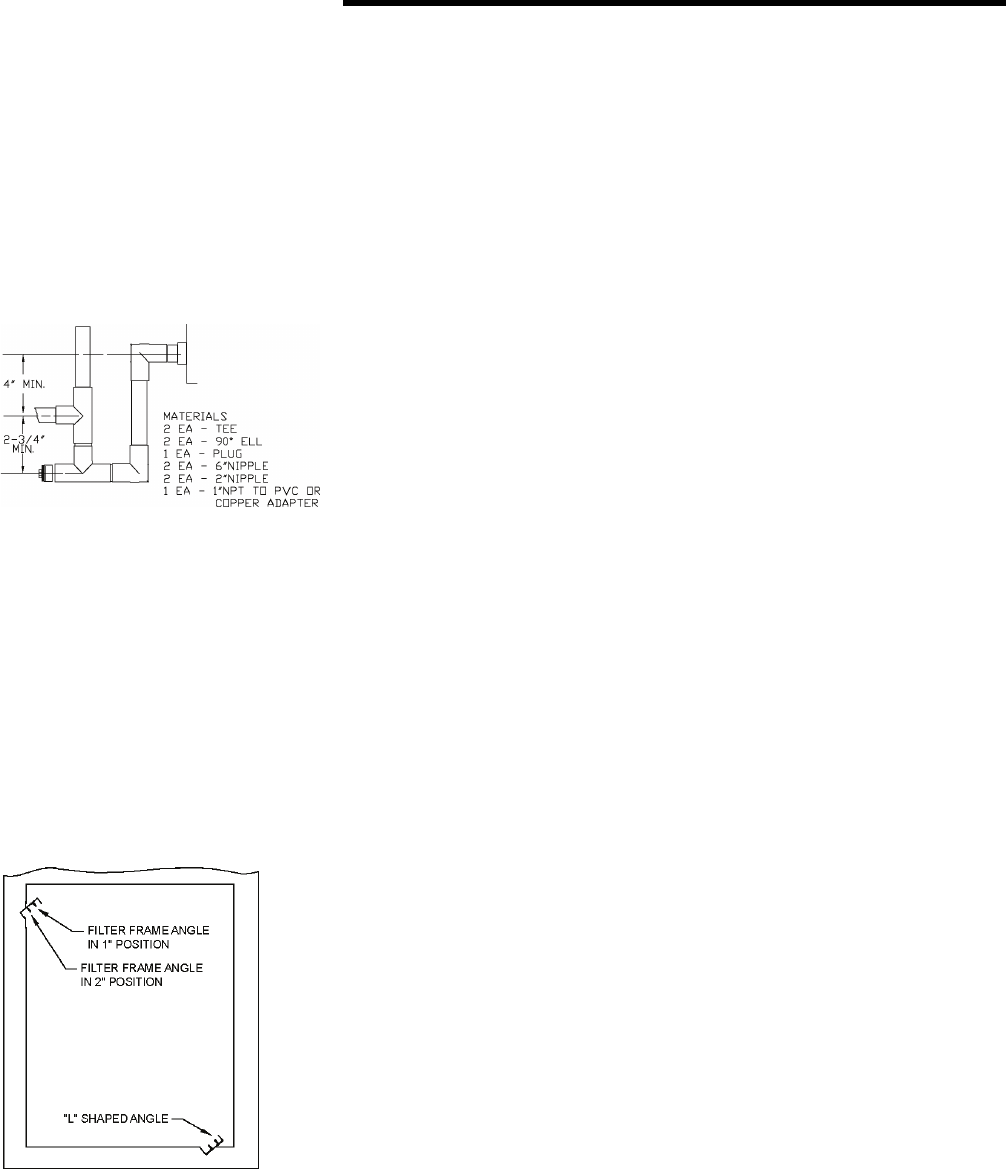

Filters

Air handlers are shipped with

throwaway filters installed. For

replacement filters consult the air

handler service facts for correct size

and number. To replace filters from

the end of the unit, remove lower

access panel (either end) and slide

old filters out and replace with new

ones. To replace from the front of the

unit, remove one "L" shaped angle.

Remove and replace filters and

reinstall "L" shaped angle. See

Figure 7.

.

To convert from 1" filter to a 2" filter

on units so equipped, remove lower

access panels from both ends of the

air handler. Remove screws and

reposition the "L" shaped angles

from both the top and bottom of the

Figure 6.

Figure 7.

filter track to increase the width of the

filter opening.

Duct Connections

The supply and return ducts should

be connected to the unit with flame

retardant duct connectors to reduce

vibration transmission. The return

duct should be sized to the same

dimensions as the return inlet of the

unit.

Note: Important! Duct flanges are

provided for attachment of

the duct work. On TWE060,

090, and 120 the flanges are

not installed but are shipped

inside the air handler. While

facing the air handler with the

control box to your left,

remove the upper access

panel. The duct flanges will

be attached to the belly band

of the air handler nearest

you. Remove the screws

securing flanges in place.

Position the four flanges

around the supply opening.

Secure with field supplied

screws, using the predrilled

holes. On TWE180 and 240,

the duct flanges are packaged

on the outside of the cabinet.

Air Flow Settings

Unit is shipped for nominal airflow

with nominal static pressure. Please

refer to fan performance table in

either the product catalog or unit

service facts and select the proper

drive package for each application.

Failure to do so could result in

improper airflow causing coil

frosting or condensate management

problems. Condensate management

problems such as water drip off or

water blow off could be the result of

too great of air face velocity across

the coil.

ƽ WARNING

Hazardous Voltage

w/Capacitors!

Disconnect all electric power,

including remote disconnects and

discharge all motor start/run

capacitors before servicing. Follow

proper lockout/tagout procedures to

ensure the power cannot be

inadvertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Failure

to disconnect power and discharge

capacitors before servicing could

result in death or serious injury.

Note: For additional information

regarding the safe discharge

of capacitors, see

PROD-SVB06A-EN or

PROD-SVB06A-FR.