30

S

TART

-

UP

P

ROCEDURE

AND

A

DJUSTMENT

SUPPLY

AIR

RETURN

AIR

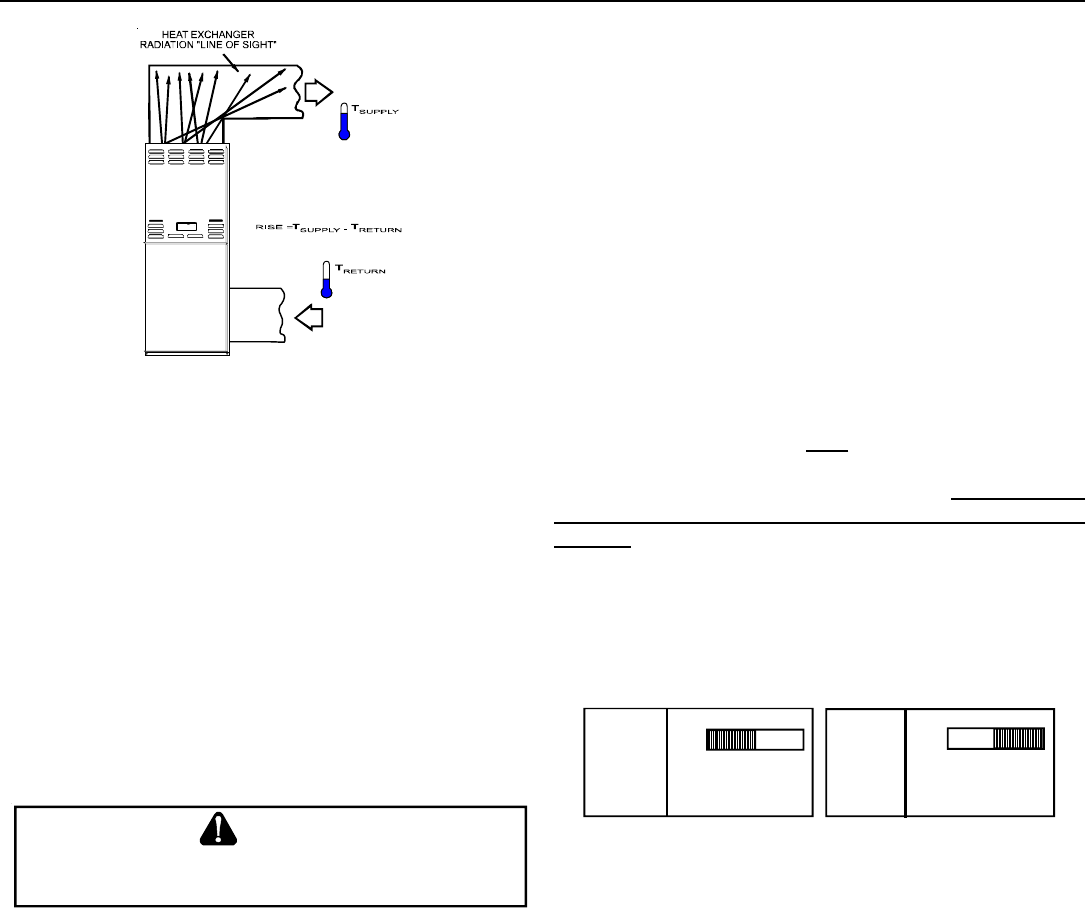

Temperature Rise Measurement

1. Operate furnace with burners firing approximately 15

minutes. Ensure all registers are open and all duct

dampers are in their final (fully or partially open) position.

2. Place thermometers in the return and supply ducts as

close to the furnace as possible. Thermometers must

not be influenced by radiant heat by being able to “see”

the heat exchanger.

3. Subtract the return air temperature from the supply air

temperature to determine the air temperature rise. Allow

adequate time for thermometer readings to stabilize.

4. Adjust temperature rise by adjusting the circulator blower

speed. Increase blower speed to reduce temperature rise.

Decrease blower speed to increase temperature rise.

Refer to the following section for speed changing details.

CIRCULATOR B LOWER S PEED A DJUSTMENT

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECT RICAL

SHOCK

,

TURN

OFF

POWER

TO

THE

FURNACE

BEFORE

CHANGING

SP EED

TAPS

.

WARNING

This furnace is equipped with a PSC circulator blower motor.

This blower provides ease in adjusting blower speeds. Refer to

the Blower Performance Data in the back of the manual for

proper selection of heating and cooling speeds. The cooling

blower speed is shipped set on HIGH. High heat ships on

MEDIUM and low heat is shipped on MEDIUM-LO. These blower

speeds should be adjusted by the installer to match the instal-

lation requirements so as to provide the correct heating tem-

perature rise and the correct cooling CFM.

To adjust the circulator blower speed, proceed as follows:

1. Turn OFF power to the furnace.

2. Select the heating and cooling blower speeds that match

the installation requirements from the airflow table in the

Specification Sheet applicable to your model. (Please

contact your distributor or our website for the applicable

Specification Sheet referred to in this manual.)

3. Relocate desired motor leads to the circulator blower

heat and cool speed terminals on the integrated control

module. (Terminals are identified as LO HEAT, HI HEAT

and COOL (hot)) for *(M,D)H8 models and HEAT and

COOL for *(M,H,D)S8 models). If a heating speed and

the cooling speed are the same, a jumper wire must be

used between the heat and cool terminals.

4. Connect all unused blower motor leads to the “PARK”

terminals on the integrated control module. Any leads

not connected to the “PARK” terminals must be taped.

5. Turn ON power to furnace.

6. Verify proper temperature rise as outlined in Temperature

Rise section.

CIRCULATOR B LOWER F AN T IMING A DJUSTMENT

NOTE: Items in this section refer to the air circulator blower

fan in the *(M,D)H8 models, NOT to the induced draft blower.

The induced draft blower timing sequence is not adjustable.

The circulator blower fan timing is adjustable only on models

with optional “heating fan OFF delay” adjustment pins or

switches. It is NOT adjustable in any other circumstances.

As shipped, the circulator blower fan will remain on for 150

seconds after the gas valve closes. When a call for cooling

occurs, the circulator fan comes on and remains on for 45 sec-

onds after the call for cooling ends. During normal heating op-

eration, the circulator fan will come on approximately 34 sec-

onds after the gas valve opens.

O

N

O

F

F

O

N

O

F

F

1

150

SECOND

DELAY

100

SECOND

DELAY

1

Switch viewed in an upflow installation.

Adjustment Switch

SETTING F URNACE O PERATING M ODE (*DH8, *ME8, AND

*MH8 MODELS ONLY)

This furnace is designed to operate with either a single gas

input rate or with two discrete gas input rates. The Mode

DIP switch is used to select the single gas input rate or two

discrete input rates.

Setting the Mode switch to “1 STG” forces the furnace to

operate at the furnace’s highest input rate only. Operation is

as described under Sequence of Operation (Integrated

Ignition Control) – Mode DIP Switch is set to “1 STG”

position.