Manual 2100-518B

Page 30 of 30

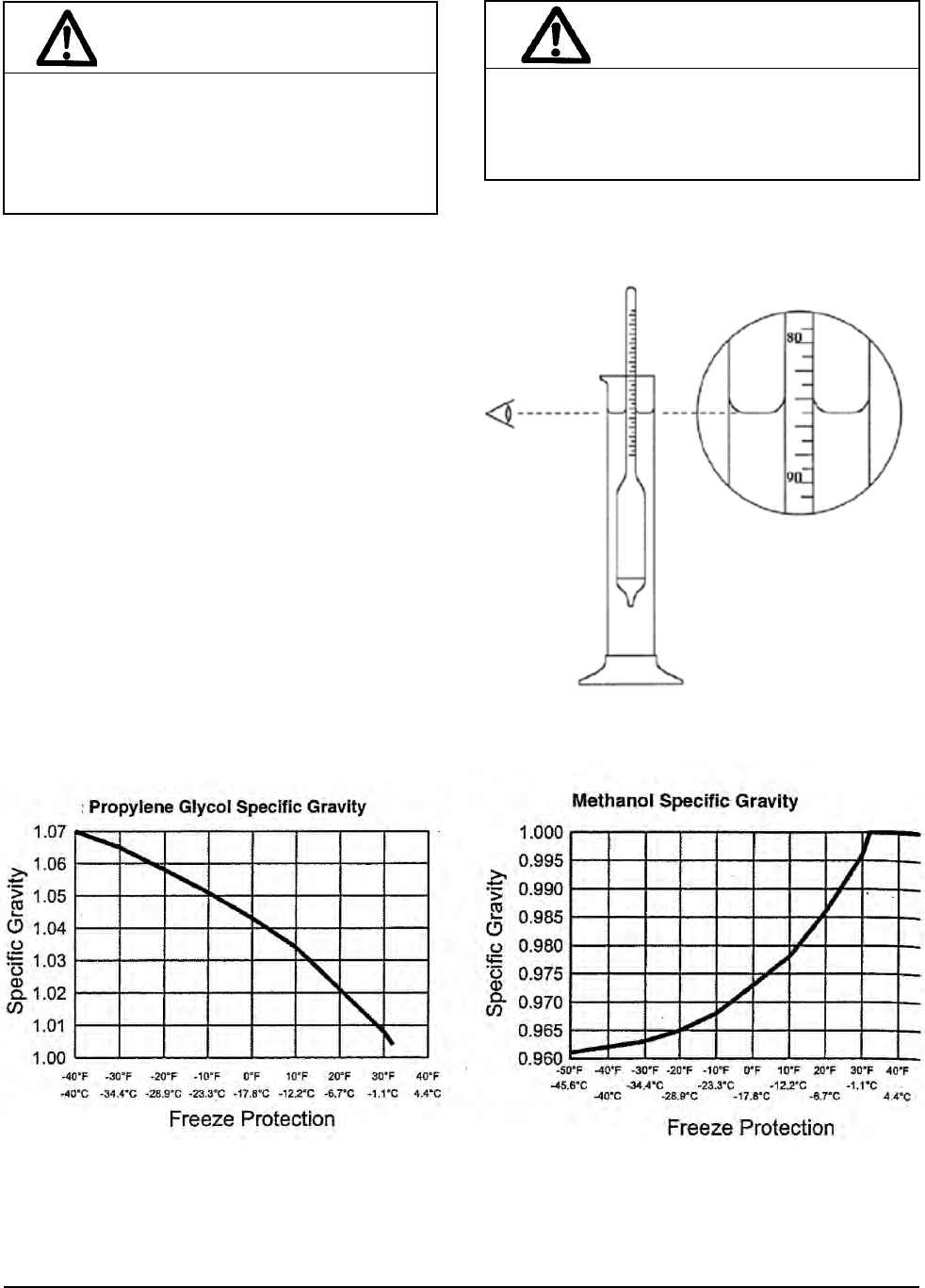

ANTIFREEZE VERIFICATION

Both Glycol and Alcohol based antifreeze solutions can

be veried to the specic percentage of volume within the

ground loop system. One of the easiest ways to check this

is through use of a Hydrometer to check the specic density

of the ground loop uid and comparing these to the charts

supplied by the antifreeze manufacturer (see Figure 11).

Hydrometers can be purchased from your local distributor

and are also available through national wholesalers.

Manual 2100-518A

Page 30 of 30

ANTIFREEZE VERIFICATION

Both Glycol and Alcohol based antifreeze solutions can be

verified to the specific percentage of volume within the

ground loop system. One of the easiest ways to check this

is through use of a Hydrometer to check the specific

density of the ground loop fluid and comparing these to the

charts supplied by the antifreeze manufacturer (see Figure

11).

Hydrometers can be purchased from your local distributor

and are also available through national wholesalers.

MIS-2666

WARNING

Always use properly marked vehicles (D.O.T.

placards) and clean/suitable/properly marked

identified containers for handling flammable

antifreeze mixtures. Post and advise those

on the jobsite of chemical use and potential

dangers of handling and storage.

CAUTION

Always obtain MSDS (material safety data

sheets) for all chemicals used in ground loop

applications - including chemicals used as

antifreeze.

FIGURE 11

DENSITY VERIFICATION

for SOLUTION STRENGTH

TABLE 6

TABLE 7

It is recommended that IGSHPA design and specifications are utilized for Loop Design, Pipe Manifolding and Hot Fusion

operations.

There are many available software programs available to aid with loop design parameters. Your local loop material or

equipment supplier may have this technology available. Technical Service has the capability to assist you in this area as well,

but it is on a first come - first serve basis.

MIS-2666

WARNING

Always use properly marked vehicles (D.O.T.

placards) and clean/suitable/properly marked

identied containers for handling ammable

antifreeze mixtures. Post and advise those

on the jobsite of chemical use and potential

dangers of handling and storage.

CAUTION

Always obtain MSDS (material safety data

sheets) for all chemicals used in ground loop

applications - including chemicals used as

antifreeze.

FIGURE 11

DENSITY VERIFICATION

for SOLUTION STRENGTH

It is recommended that IGSHPA design and specications are utilized for Loop Design, Pipe Manifolding and Hot Fusion

operations.

There are many available software programs available to aid with loop design parameters. Your local loop material or equipment

supplier may have this technology available. Technical Service has the capability to assist you in this area as well, but it is on a

rst come - rst serve basis.