Manual 2100-518B

Page 29 of 30

Propylene Glycol – Non-toxic, non-corrosive,

expensive, hard to handle when cold, poorest heat transfer,

has formed “slime-type” coatings inside system piping.

Propylene Glycol is acceptable in systems anticipating

loop temperatures no colder than 40°F (4.4°C). These

systems typically use antifreeze because of low ambient

conditions (outside plumbing or cooling tower, etc.).

When loop temperatures are below 40°F, the uid becomes

very difcult to pump and heat transfer characteristics

suffer greatly. Only food grade propylene glycol is

recommended to prevent the corrosion inhibitors from

reacting with local water causing “slime-type” coatings

inside heat exchangers. If propylene glycol must be

used (code requirements), careful consideration of loop

Reynolds numbers, pump selection and pressure drop must

be considered.

Potassium Acetate (GS4) – Non-toxic, good heat

transfer, high price, non-corrosive with added inhibitors,

low viscosity. Due to its low surface tension, Potassium

Acetate has been known to leak through mechanical

ttings and certain thread sealants. A variant of the salt

family, it can be extremely corrosive when exposed to air.

Potassium Acetate is not recommended in ground loop

applications due to the leaking and (ultimately) corrosion

problems associated with it.

NOTE: Consult with your local distributor if you have

questions regarding antifreeze selection and any comments

to report about problems or success with any particular

methods in your area.

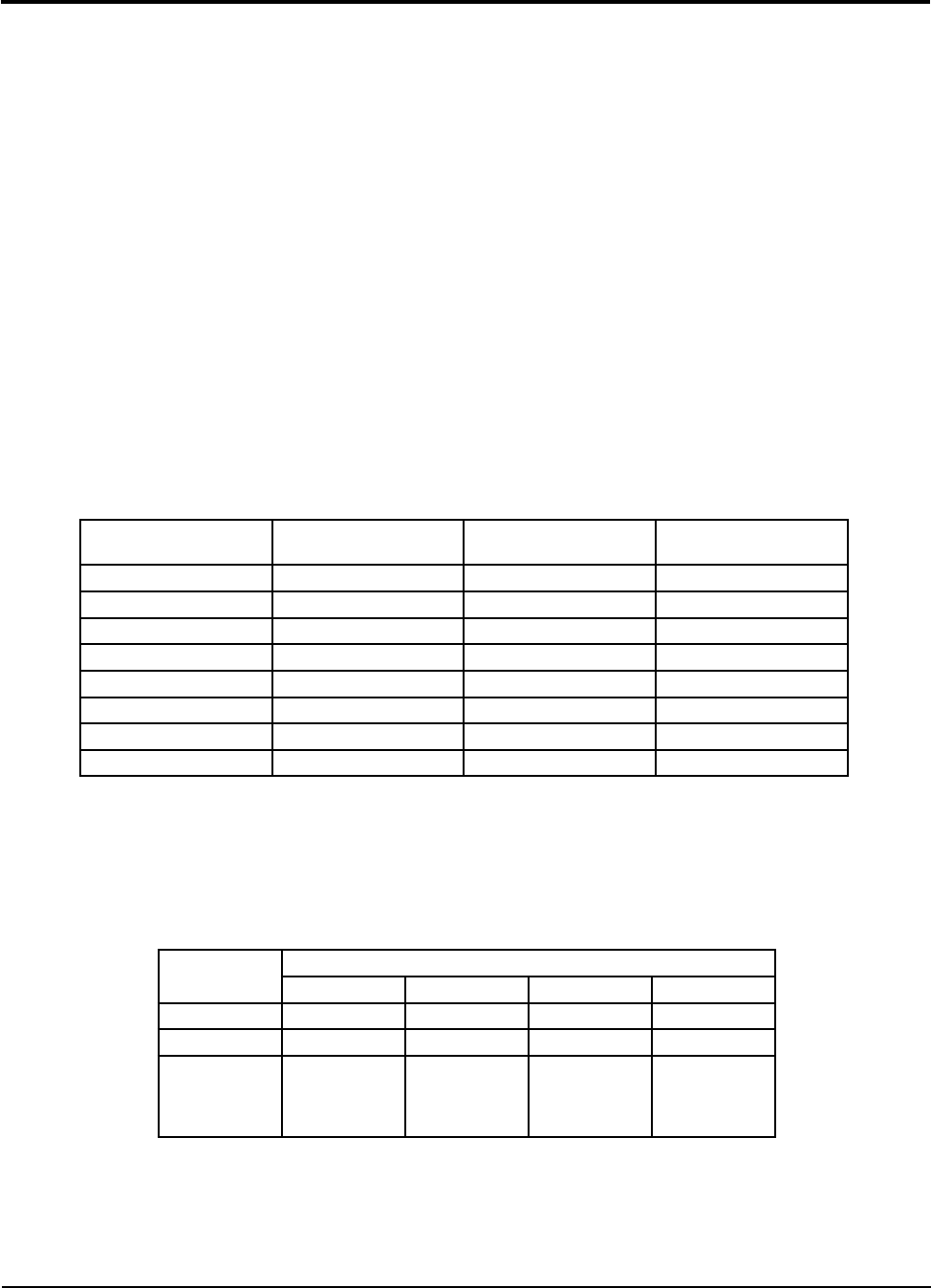

TYPE SIZE

VOLUME

(U.S. GALLON/100'PIPE)

VOLUME

(LITERS/10 METERS)

Copper 1" CTS 4.1 15.5

Copper 1-1/4" CTS 6.4 24.2

Copper 1-1/2" CTS 9.2 34.8

Polyethylene 3/4" - IPS SDR 11 3.0 11.4

Polyethylene 1" - IPS SDR 11 4.7 17.8

Polyethylene 1-1/4" - IPS SDR 11 7.5 28.4

Polyethylene 1-1/2" - IPS SDR 11 9.8 37.1

Polyethylene 2" - IPS SDR 11 15.4 58.3

Type

Minimum Temperature for Freeze Protection

10°F (-12.2°C) 15°F (-9.4°C) 20°F (-6.7°C) 25°F (-3.9°C)

Methanol 25% 21% 16% 10%

Ethanol * 29% 25% 20% 14%

100% USP

Food Grade

Propylene

Glycol

27% 24% 20% 13%

ANTIFREEZE SELECTION & USE (CONTINUED)

TABLE 4

FLUID VOLUME

TABLE 5

PERCENTAGES BY VOLUME

Approximate Fluid Volume per 100’ (10 Meters) of Pipe

Antifreeze Percentages by Volume

* Must not be denatured with any petroleum based product.