Installing Wall Inlet Models CVIV60A or CVIV60W

CAUTION: INSTALLATION WORK AND ELECTRICAL WIRING MUST

BE DONE BY QUALIFIED PERSON(S) IN ACCORDANCE WITH ALL APPLICABLE

CODES AND STANDARDS, INCLUDING FIRE-RELATED CONSTRUCTION.

CAUTION: MAKE SURE POWER IS SWITCHED OFF AT SERVICE PANEL

BEFORE STARTING INSTALLATION.

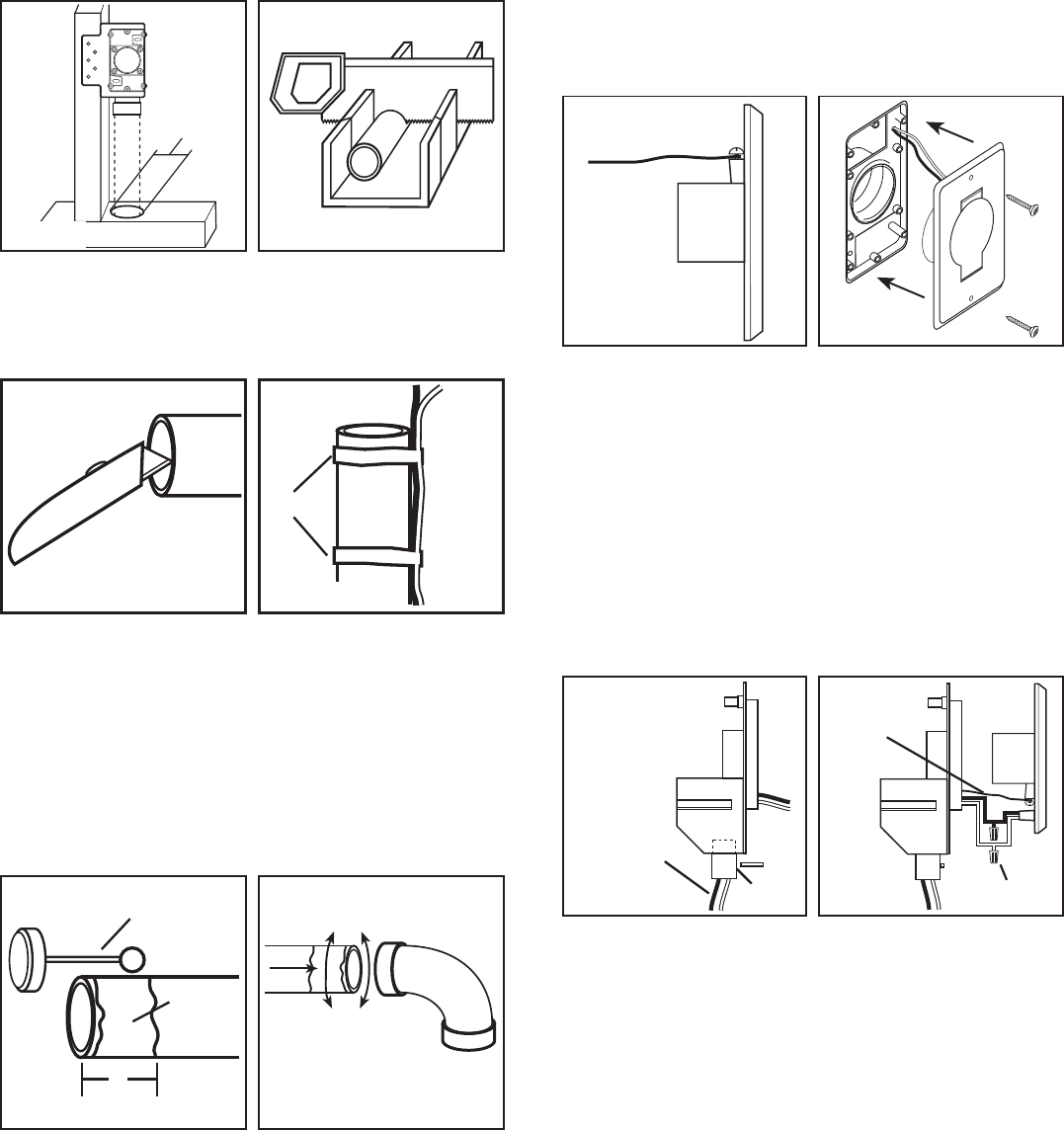

1. Once the drywall has been completed, the wall inlets can be installed. Start

by checking the mounting plate for any debris that might have been left

from the drywall process and clean if necessary.

2. Connect the low voltage wire to the terminal screws on the rear of the wall

inlet (Figure 11).

3. Align the inlet screw holes with the mounting plate holes and press the inlet

into place, guiding any extra wire back through the mounting plate as you

go. Attach wall inlet to mounting plate with provided screws (Figure 12).

Installing Electric Wall Inlet Models CVIV65A or CVIV65W

CAUTION: INSTALLATION WORK AND ELECTRICAL WIRING MUST

BE DONE BY QUALIFIED PERSON(S) IN ACCORDANCE WITH ALL APPLICABLE

CODES AND STANDARDS, INCLUDING FIRE-RELATED CONSTRUCTION.

CAUTION: MAKE SURE POWER IS SWITCHED OFF AT SERVICE PANEL

BEFORE STARTING INSTALLATION.

1. Before the drywall is installed, run wire from a nearby electrical outlet box

or junction box through the supplied strain relief and into the hole in the

mounting plate, leaving about 10" of excess to make the connections to the

inlet. Secure the wire in place by tightening the strain relief (Figure 13).

2. Cap the loose wires and tuck back inside of mounting plate. Once the drywall

has been completed the wall inlets can be installed. Start by checking the

mounting plate for any debris that might have been left from the drywall

process and clean if necessary.

3. Connect the low voltage wire to the terminal screws on the rear of the wall

inlet. Second connect the black wire from the supply to the black wire of

the inlet, then connect the white wire from the supply to the white wire of

the inlet. Use approved electrical wire nuts for all connections (Figure 14).

4. Align the inlet screw holes with the mounting plate holes and press the inlet

into place, guiding any extra wire back through the mounting plate as you

go. Attach wall inlet to mounting plate with provided screws (Figure 12).

NOTE: The electrified wall inlet should be listed on the inspection report for

building inspection purposes.

Installing the Tubing

NOTE: When installing the tubing, start at the farthest inlet and work towards

the power unit. Keep the tubing as straight as possible with the least amount

of elbows and tees as possible to ensure maximum performance of your system.

When installing tees or elbows, make sure the curve in the fitting is aligned so

that the air flow is towards the power unit.

1. Cut a 2-1/2" diameter hole in the sole plate, header, or stud directly in line

with the opening of the inlet fitting (Figure 5).

2. Measure the length of tubing needed to connect into the main trunk line,

adding approximately 3/4" of tubing for insertion into fittings.

3. Cut the tubing, taking care to keep the straight square edge. The use of a

miter box is recommended (Figure 6).

4. Remove rough edges with a utility knife or coarse sand paper (Figure 7).

5. Dry fit all pieces and ensure proper fit and alignment before cementing.

6. When dry fitting tubing, run low voltage wire (minimum, solid 18 gauge, two

conductor) by securing to tubing with tape. Allow approximately 6" of excess

wire for connection to each inlet (Figure 8).

NOTE: PVC solvent cement “welds” the fitting to the tubing through a chemical

reaction to produce an air tight seal. It is important to make sure all surfaces

are clean and free of burrs to ensure a proper seal.

7. Once all tubing has been cut, cleaned, and checked for fit, apply model

CVFA35 PVC cement (not included) or equivalent cement to the outside of

the tubing covering about 1". DO NOT allow any of the cement to enter the

inside of the tubing (Figure 9).

8. Insert tubing with cement into fitting with a twisting motion to ensure the

cement has been evenly spread. Check that the tubing is evenly seated in

the fitting and is aligned properly with the rest of the line (Figure 10).

2-1/4"

Tape

Low

Voltage

Wire

Extra wire for inlet

connection

Cement

1"

Cement

Applicator

Strain

Relief

Supply

Wires from

Electrical Box

Wire Nut

Low

Voltage

Wire

000000 Rev A. 3-05

www.airkinglimited.com

3 of 16

Figure 5 Figure 6

Figure 7 Figure 8

Figure 9 Figure 10

Figure 11 Figure 12

Figure 13 Figure 14