1110

Fully Bonded System – Solid wood and

engineered boards can be fully bonded on

to flat and level screeds (see Substrates,

page 8). It is imperative however that the

screed is sufficiently dry. If the screed has a

relative humidity reading of over 60%, a

wood floor must not be laid over it without

the application of a surface damp proof

membrane such as Sika Primer MB. Follow

the manufacturer’s instructions rigidly to

ensure the membrane is fully effective.

Fired Earth recommends that at least one

coat of Sika Primer MB is applied to a

screed even if the screed is believed to be

60% RH or below.

CLIP SYSTEM – Boards being laid using the

CLIP SYSTEM should be fitted directly onto

the polythene membrane which has been

overlaid with Fired Earth Wood Underlay.

b. Engineered Boards

The subfloor should be level prior to

installation of a wood floor. Fired Earth

Universal Levelling Compound can be

used on screeded floors up to a maximum

depth of 5mm to level the substrate

when necessary.

Fired Earth Wood Underlay should be fitted to

cushion the floor after laying a suitable

polythene 250mu sheet (Visqueen) to provide

a DPM. Lay the Fired Earth Wood Underlay

so joins run in the opposite direction to

the timber floor.

Existing Timber Base

A new wood floor should be laid at a 90

degree angle to the existing boards. If the

new boards are to be laid in the same

direction as the old, plywood sheets

(minimum depth 6mm) should be nailed or

screwed to cover the existing floor, allowing

a 15mm perimeter gap for expansion. Loose

boards etc. should be firmly fixed to reduce

the risk of squeaking in the new floor.

a. Solid Boards

When laying suitable new wood boards

directly onto existing joists, noggins may be

required to support the end joins.

Suspended ground floors must have

sufficient cross ventilation to prevent

condensation occurring on the underside of

the flooring. It is advisable to lay a suitable

membrane over the joists to help protect

the undersides of the new boards from

moisture. Fix the boards by secret nailing.

b. Engineered Boards and Solid Wood

using the CLIP SYSTEM (128MM WIDE

SOLID WOOD BOARDS ONLY).

The subfloor must be flat to ensure the

boards are fully supported. Use WBP plywood

of a suitable depth to level the floor prior to

fitting the underlay and wood if required.

Sound and Impact Reductions

In order to reduce sound impact noise in

solid wood floors when fitting onto

concrete floors, Sika AcouBond system can

be used. The synthetic foam mat is laid

onto the subfloor. Sika T52 adhesive is then

applied into the preset channels within the

underlay. This system also ensures that a

high bond strength is achieved and is

slightly ‘forgiving’ in uneven subfloors.

Stage 2 - Installation

Setting out

Allow ample time to study the room and to

plan your work. After consultation between

client and fitter and selection of a starting

point, mark out a straight line parallel to

the chosen wall, allowing a 15mm gap for

expansion. Check for straightness with

other walls and in adjoining rooms if the

boards are to continue into them. It may be

necessary to scribe the first row of boards

to achieve correct alignment throughout

the area(s) to be fitted. All end joints should

have a minimum overlap of 300mm from

the board ends on either side, and be

staggered throughout the floor to achieve

a random effect and strength particularly

when fitted onto battens or joists.

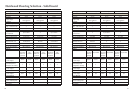

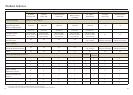

a. Solid Boards

Secret Nailing - Square the first run of

boards to the marked line and top nail and

countersink through the boards as near to

the wall as possible (see diagram below).

Top nail at 25-30cm intervals or onto every

joist, and where possible within 7.5cm of

the end of each board. Care must be taken

with presealed boards, not to damage the

surface. Remember to thoroughly mix

boards for colour, texture, grain, width etc.

as the floor is fitted.

Using the same spacing of 25-30cm, secret

nail at 45 degrees and countersink through

the tongue, it will not be possible to use

the Porta Nailer on the first and possibly

second row of boards, nearest to the

starting and finishing walls. Therefore a

pilot hole should be drilled and nails

hammered home and countersunk).

Fit the next run of boards groove to tongue

and secret nail. Continue to fit the boards

from left to right remembering to stagger

the joints by a minimum of 300mm. Trim

the last boards to fit, allowing 15mm for

expansion, use offcuts to start the next

row of boards where possible. Check the

straightness of your work as you progress.

Top nail and countersink the last run of

15mm expansion gap

Secret nail

Top nail countersunk

Skirting