98

Substrates

All substrates must be structurally sound,

flat, clean and dry. The normal tolerances

are +/- 3mm over a 2.0m straight edge.

Uneven floors should be levelled with Fired

Earth Universal Levelling Compound or

battens and packers depending on the

fixing system to be used. The surface

should be free of all contaminants and

loose material. All possibilities of damp e.g.

walls, drains, damp proof courses,

plumbing, fridges, washing machines etc.

MUST be thoroughly checked and repaired

if found to be leaking.

In particular all construction dampness

must have completely dried and the house

should be at the temperature and humidity

expected during occupation.

Sand and Cement Screed/Concrete

Existing screeds/concrete must be checked

for moisture. This can easily be carried out

using a moisture meter. If moisture is

present, i.e. over 5% (equivalent to 60% RH

with a hygrometer), wood floors must not

be fitted until the problem has been

rectified. Please seek specialist advice.

Existing Timber Base

e.g. Joists, tongue and grooved

floorboards and floating floors.

a. Solid Boards

Can be fixed directly over sound and secure

joists, or directly onto prepared floorboards.

If the existing floorboards are sufficiently

flat, the new boards can be laid directly on

to them at 90 degrees. If the existing floor

is not suitably flat then it must be made

flat and level by overlaying with WBP

(water and boil proof) plywood. Loose

boards must be secured or the new floor

may squeak. Please note: If nails/screws are

being used, care must be taken not to

damage pipes or electrical cables beneath.

b. Engineered Boards or CLIP SYSTEM

This cannot be fitted directly onto joists.

Existing wooden floors must be made flat

and level prior to installation of the overlay

boards. Plywood of a minimum depth of

12mm, should be firmly screwed down to

level uneven timber bases.

Floating Floor

All Fired Earth timber floors can be fitted

onto floating floors, which must be sound,

flat, firm and free of any deflection. When

the boards are to be installed by secret

nailing, a minimum 12mm depth wbp

plywood must be screw fixed to the

chipboard at 300mm centres.

Other Floor Finishes

Most other floor finishes e.g. lino, carpet

etc. should be removed prior to installation

of a new wood floor. Please ask for

further advice.

Fixing

There are a number of methods for fixing

wood floors. Fired Earth recommends that

solid boards are ‘secret nailed’, using the

Porta Nail system, fully bonded using

Sika

T54

or floated on our CLIP SYSTEM.

Engineered boards are floated onto a

suitable underlay. Where floor height is

critical, engineered boards can be fitted

over an underlay which minimises height

gain, solid wood can be glued down,

128mm boards can be fitted with the CLIP

SYSTEM or, floorboards can be removed to

allow for nailing solid boards directly to

the joists.

Prior to installing the wood, it should be

thoroughly checked to ensure that the

colour is correct and the boards are

straight and undamaged. Any damaged

boards should be put to one side and used

for cuts or in less obvious areas. Ensure the

various shades, grades and widths where

applicable of wood are randomly

distributed throughout the floor. The wood

fitter must assess each board as it is being

laid for suitability. If you are in any doubt,

please consult your Fired Earth Showroom

prior to installing.

A final moisture check should be conducted

immediately prior to installation. The wood

to be installed should be within +/- 2%

moisture of the surface onto which it is to

be fitted.

The exception to this is a subfloor with a

surface DPM applied, which should not

require checking and must not be damaged

during installation of the floor. Fired Earth

recommend Protimeter’s MMS test

equipment for measuring moisture content,

relative humidity and temperature.

Sand and cement screeds/concrete

a. Solid Boards

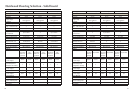

Secret Nailing - Lay a suitable polythene

250mu sheet (Visqueen) vapour barrier

onto the substrate, overlap any seams by at

least 20cm and securely tape to provide a

suitable seal. The polythene should be

returned up the walls by 50mm, excess can

be cut off once the floor is laid. Lay 18-

24mm WBP plywood across the floor in the

opposite direction to the length of the new

boards, to provide a material into which

the nails can fix. The plywood sheets

should be butted together allowing a

perimeter gap for expansion. Alternatively,

kiln dried and treated timber battens 50 x

25mm, may be laid on to the floor at a

maximum of 400mm centres, see diagram

on next page.

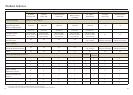

Stage 1 - Preparation