',60$17/,1*7+(),5(35,2572,167$//,1*

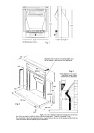

The lower front panel assembly is removed by lifting upwards and pulling forwards. Remove the canopy to gain

access to the Bezel or (Goal post trim) securing screws. The canopy is held in position by dimpled spring clips on

both the side flanges, remove by exerting an even pull forward. See Fig 11.

Remove the outer bezel/Goal post trim by unscrewing the four M4 taptite screws on the inner flanges and the four No

8 self tapping screws in the corners.

It will be necessary to dismantle the burner from the convector box before installing the box in the opening, to

remove the burner, unscrew the two screws securing the fibre back/ side cheek assembly in position and remove,

remove the coal support shelf and burner inserts. Unscrew the two screws at the base of the aperture in the fascia

panel and withdraw the burner.

,167$//,1*7+($33/,$1&(,1326,7,21

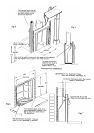

With the gas supply pipe laid to the required position and the surround fitted and sealed to the chimney correctly –

this is to prevent any seepage of the flue products and to prevent any ingress of air into the flue from anywhere other

than the flue outlet of the fire. The method to be used to secure the appliance in position is either screwed directly

onto the front face of the back panel through the mounting brackets or fixed to the internal side walls of the builders

opening using the four fixing brackets provided. These can be rotated to accommodate most openings, as shown in

Fig 14: plastic plugs and wood screws are supplied for these brackets.

It is very important when fitting the trim, that when it is secured in position, that the rear of the trim has an effective

seal with the back panel or fixing wall. ( A seal is fitted to the trim during manufacture).

Continue the supply and replace the burner ensuring that the rear legs locate in the two up-formed tags in the base

plate and complete the gas connection to the burner. Replace the canopy.

NOTE: Before offering the convector box into the opening, the hearth should be protected from damage or scratches

that may occur during installation.

The complete installation should be tested for Gas soundness.

IT IS VERY IMPORTANT THAT THE RESTRICTOR PLATES ARE REMOVED AND THE SCREWS

REPLACED WHEN THE APPLIANCE IS INSTALLED INTO EITHER A PRE-CAST OR A 5in (125mm)

DIAMETER FLUE.

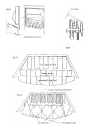

$66(0%/<2)7+()8(/%('&20321(176

1. Locate the fibre back/side cheek assembly in position.

2. Place the coal support shelf on the stainless steel channel, the machined groove on the underside of the shelf is

located on the rear flange of the channel.

3. Place the two shaped burner inserts in channel between the two burner flame ports, (check that a minimum gap of

approx. 6mm is maintained between the rear of the burner insert and the front edge of the coal support shelf).

4. Position the front simulated coal on the shelf provided above the control facia panel. See fig 20.

&2$//$<287

Position 3 large coals, 2 triangular and 4 large coals on edge (straddle the gaps of the coal support shelf and run

the strata front to rear) as the first layer (fig. 21). Place 4 medium as a second layer sitting on the gaps of the front

coals and resting against the rear coals.(fig 22). Finally place the remaining 5 small coals as shown in fig 23. Small

adjustments to the coal layout may be made to give the best visual appearance however, additional coals must

not be used. If any fibre component is lost or broken the appliance must not be used until a replacement is

obtained.

Page 7