APPLICATION OF THE HIGH SPEED

300 RPM FLOOR MACHINES

(MODELS P203 and P173)

Spray Buffing to revitalize an existing floor finish to a “wet look”

shine especially in heavy traffic areas using a Powr-HD™ yellow or

natural hoghair blend pad.

Dry Buffing with a brush on uneven floors coated with a buffable

finish or with a Powr-HD™ tan, beige or white pad on even floor

surfaces.

OPERATIONS OF THE HIGH SPEED

300 RPM

(MODELS P203 and P172)

Follow the same operation procedures described for 175 RPM

machines.

APPLICATION OF THE DUAL SPEED

175/320 RPM MACHINES

(MODELS P202 and P172)

The Powr-Flite

®

dual speed machines will operate in a broad

range of applications. These machines perform all the applications

of the 175 RPM standard speed machines and the 300 RPM high

speed machines except the specialized applications.

Do not use dual speed machines for sanding, grinding or

scraping.

The dual speed machines are specially designed for spray cleaning

of heavy traffic areas.

OPERATION OF THE DUAL SPEED

MACHINES

Follow the operation procedures described for 175 RPM machines.

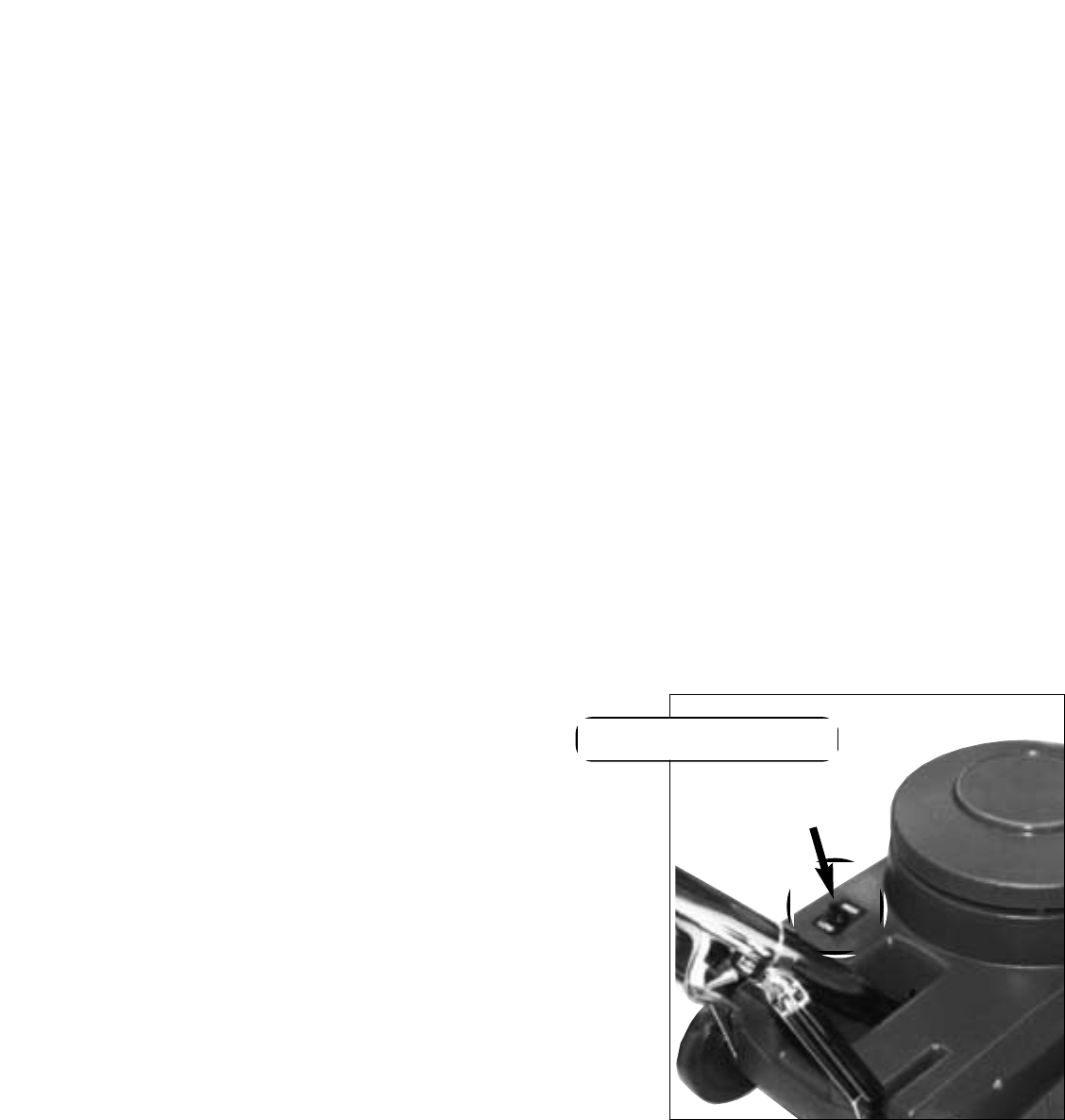

The proper speed selection is important to properly operate these

machines. Speed selection Low (175 RPM) or High (320 RPM)

is made with the switch located on the base and motor housing.

(See Picture #4)

Stripping, scrubbing, bonnet cleaning and shampooing should be

performed at 175 RPM Low Speed.

Spray buffing and dry buffing should be performed at 320 RPM,

High Speed.

Spray cleaning is a two speed maintenance operation. Apply a

spray buff chemical such as Powr-Glo

®

to the floor ahead of the

machine. Make the first passes through the spray buff at low

speed with an open weave pad such as the Powr-HD™ blue

cleaner pad or the brown hoghair blend spray cleaner pad.

Remove the spray cleaning pad and place a buffing pad on the

machine such as Powr-HD™ yellow, beige or natural hoghair

blend pads.

Switch the speed to High 320 RPM and buff the dulled finish to a

high gloss.

Unplug the power cord and wrap it under the cord hook and over

the right handle grip. Clean the cord off to prevent heavy soiling

and cleaning residues from building up on the cord. This is a

good time to inspect the cord for cuts, gashes and loose prongs.

Tip the machine back and remove the pad and the drive block or

brush.

Picture #4

The condition of the floor pad or brush has a direct affect on the

performance of your floor machine. When the pad becomes dirty,

turn it over and use the other side. When finished, wash the pad

or brush and allow it to dry completely before using it again.

Stand the wet brush on the bristles until dry, then hang up the

brush.

Do not store the machine with the drive block, pad or

brush on the machine.

Wipe off the machine housing and wheels to prevent build-up of

unnecessary residue.

TRANSPORTING THE MACHINE

Place the handle in the upright position. Lock the handle cam

release lever. Tip the machine back and transport on the wheels.

MAINTENANCE FOR THE P201,

P203, P171, P173, P131, P201HD,

P171HD, P202

and P172

Once a month remove the motor cover of the unplugged machine by

pulling evenly, but firmly, with both hands until the cover is removed.

Vacuum out any dust or debriswhich has accumulated on the motor.

Replace the motor cover by setting it over the holes in the hous-

ing and firmly pushing it down.

Check and maintain the tightness of all the fasteners.

WARNING: Do not over-tighten the switch housing screws.

Keep the machine clean especially at the handle tube and collar

so the handle tube will move freely through the collar.

Inspect the cord for cuts, gashes, or loose prongs; replace as

needed.

Disassembly of this motor voids the warranty. Improper

disassembly and assembly of this motor can permanently damage

the field or rotor.

For P202 & P172 only: The length of the carbon brushes should

be inspected annually. If they are no longer extended past the hold-

er window, they should be replaced. Replacement of the carbon

brushes should only be done by a qualified service technician.

Speed Switch