14

Servicing

All servicing activities must be performed by a qualified service t chnician or a service agency. The home owner may not

e

hecking and Adjusting the Gas Manifold Pressure

manifold pressures as shown in “Technical Data”. It is

roceed as follows:

the HI mode.

g screw “C” (pressure regulator) to the value given in “Technical Data”. Turn clockwise to

3. to LO mode. The position in which this occurs depends on

4. rect value for the LO pressure is achieved. Turn clockwise to decrease the pressure, turn

5. de to check that both the HI and LO pressures are correct. A tolerance of plus or minus

6. ection, then check for gas leaks from it.

T H

hecking, Removing and Reassembling of the Vent Air Intake System

verify it is clean from dust and

ted by hand.

must be taken outside. Do not push

4.

three outer screws.

ubrication of Moving Parts

tion. Do not try to lubricate any part of the furnace such as motors bearings, keys, knobs,

lame Visual Check

ion may be checked by examining the burner flame. The flame may be examined through the front

e

service the furnace. The home owner must read this section to be informed of the periodic maintenance and checks that ar

required. All servicing (except on vent system) must be performed with the external casing removed. After any servicing, the

external casing must be reinstalled properly.

C

The furnace comes set from the factory at the correct HI and LO gas

recommended to check the pressures periodically (minimum once a year). If adjustment is required, this can be done by

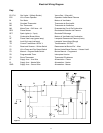

adjusting screws “C” and “D”. (Figure 8) A test gauge must be connected as explained in “Checking the Gas Manifold

Pressure”.

P

1. Place the unit in

2. Adjust the HI pressure by turnin

increase the pressure, turn counterclockwise to decrease it.

Turn the control knob clockwise until the gas control switches

the actual room temperature.

Loosen screw “D” until the cor

counterclockwise to increase it.

Switch the unit from LO to HI mo

0.1-inches w.c. on the pressure value is acceptable. Readjust if needed.

Disconnect the test gauge and firmly tighten the screw of the gauge conn

he I and LO pressures must be adjusted as instructed above. Never adjust them independently of each other.

C

It is essential that the vent air intake system is examined periodically (minimum once a year) to

deposits of solid materials such as leaves or nests. The vent air intake system is checked from outside. Proceed as follows:

1. Remove the vent cap by removing the three outer screws. (Figure 7)

2. Remove the inner flue pipe. Do not use tools; the pipe can be extrac

3. Remove dust and deposits from the vent cap and flue pipes. Deposits in the air pipe

them inside the furnace. The outer air pipe may not be removed from outside.

Reinstall the flue pipe from outside. Do not use glue or sealants.

5. Reinstall the vent cap on the flue pipe. Do not use glue or sealants. Tighten the

L

This furnace does not require lubrica

screws, etc.

F

Correct and proper operat

flame viewer. The flame must be stable and have blue color. Some small yellow tips are acceptable with propane gas. If the

flame is yellow or has excessive turbulence, check the gas manifold pressure and the vent air intake system. If these are not

acceptable, call a qualified service technician for a complete check of the furnace. Call also your gas supplier to check the

composition of the gas in use.