2

Type 3098-134 is equipped with a “high-mass” element,

and is used in applications where a medium sensor

response time (typically 45 to 60 seconds) is desired.

Type 3098-156 contains a “low-mass” element, and is

used in applications where a short response time (usually

between 30 to 45 seconds) is required.

In general, consideration for response time is based on

whether or not the control system uses some form of pre-

purge or fan delay timer. Systems using delay timers may

require the use of the low-mass 3098-156 so that the

element responds to the pilot before the delay time has

elapsed.

This is especially true in cases where roof-top units are

equipped with delay timers and are subjected to low

ambients (20°F or less). The low ambient slightly increases

the “heat-up time” for the flame sensor. The use of the

3098-156 reduces the time lag between the original call

for heat and the time the main burner comes on. This

causes main burner operation to occur shortly before the

system blower comes on, preventing cold air drafts on

start up.

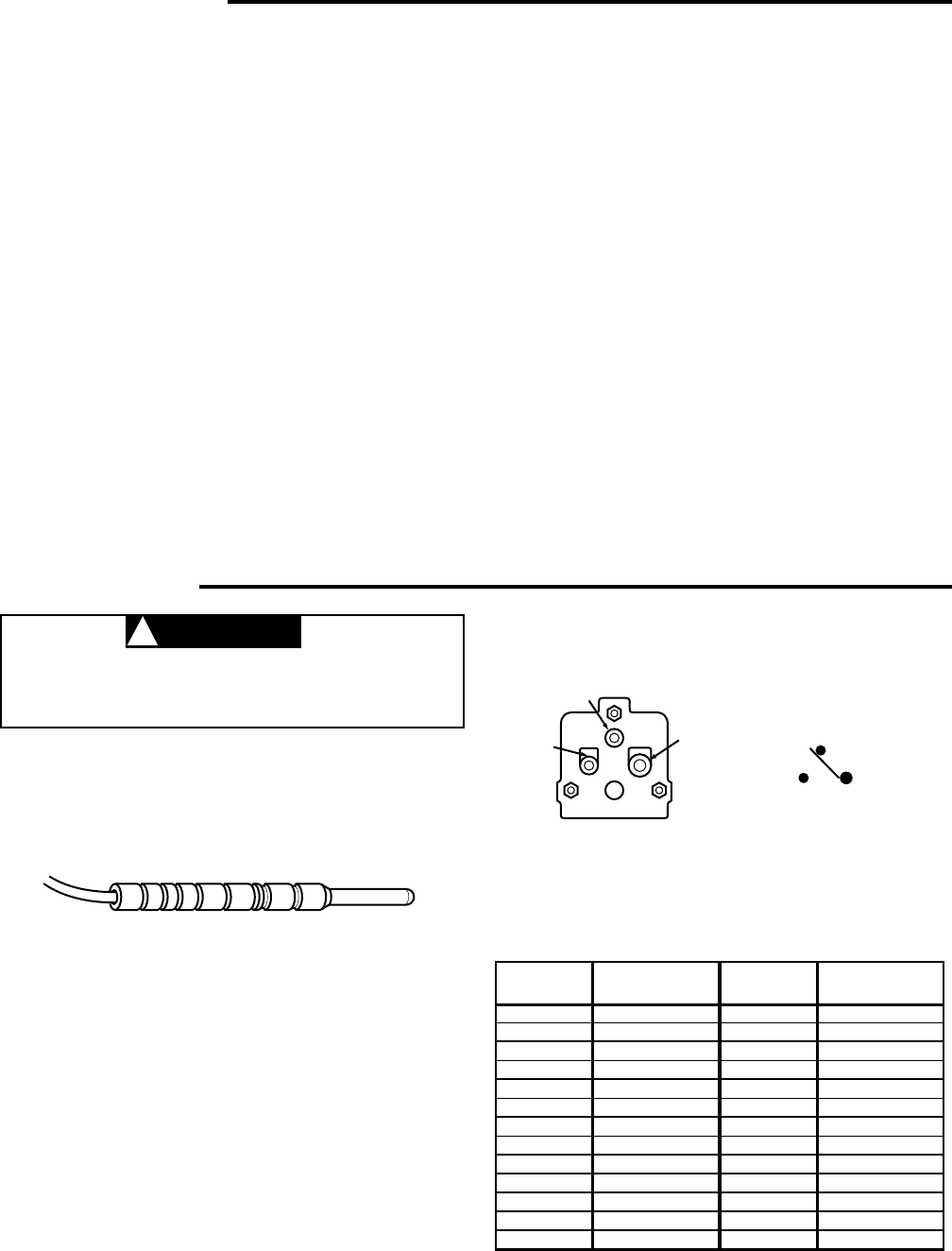

SPECIFICATIONS

Electrical Rating: 3 Amps @ 24 VAC

1 Amp @ 120 VAC

0.5 Amps @ 240 VAC

Switch Action: SPDT

Capillary Length: 48 Inches

Sensing Bulb Type: Universal Replacement

Thermocouple “slip-in”

Terminal Designations: 2 - Normally Open

3 - Normally Closed

4 - Common

INSTALLATION

To avoid personal injury and/or property damage,

shut off gas and electric to heating system until

installation is complete.

1. Turn off gas and power until replacement is complete.

2. Remove defective flame sensor from pilot burner and

unplug from gas valve.

3. Align tip of defective flame sensor with tip of replace-

ment . Do not uncoil capillary of new flame sensor.

4. Note the location of the C-rings on the defective

sensor bulb and install C-rings on the replacement in

the same locations.

5. Insert replacement sensor in pilot burner. Uncoil only

enough capillary to allow sensor to be installed. Be

sure new sensing bulb is in the same position as the

unit it is replacing.

6. Carefully uncoil capillary of new sensor by grasping

capillary at switchcase and sensing bulb, then “stretch”

coil until switchcase reaches gas valve plug. Care-

fully align switchcase with gas valve socket and plug

flame sensor into valve.

7. Turn on gas and power. Cycle system a number of

times to insure proper operation.

CAUTION

!

OEM

MODEL NO.

3098-1

3098-111

3098-117

3098-120

3098-122

3098-124

3098-126

3098-127E1

3098-127E2

3098-130

3098-131

3098-134

3098-135

WHOLESALE

REPLACEMENT

3098-134

3098-134

3098-135

3098-135

3098-156

3098-156

3098-156

3098-134

3098-156

3098-156

3098-156

3098-134

3098-135

OEM

MODEL NO.

3098-136E1

3098-136E2

3098-137

3098-139

3098-140

3098-141

3098-142

3098-143

3098-144

3098-147

3098-148

3098-149

3098-153

WHOLESALE

REPLACEMENT

3098-134

3098-156

None

None

3098-140

3098-134

3098-156

3098-156

3098-156

3098-134

None

3098-156

3098-156

MERCURY FLAME SENSOR CROSS REFERENCE

Contact the O.E.M. (Original Equipment Manufacturer)

for replacements not listed in cross reference

Pin 2

(small)

Pin 3

(small)

Pin 4

(large)

24

3

Internal Schematic

4

(COM)

3

(COLD)

2

(HOT)

N.C.

N.O.