2

CONVERTIBLE CONTROLS CONT.

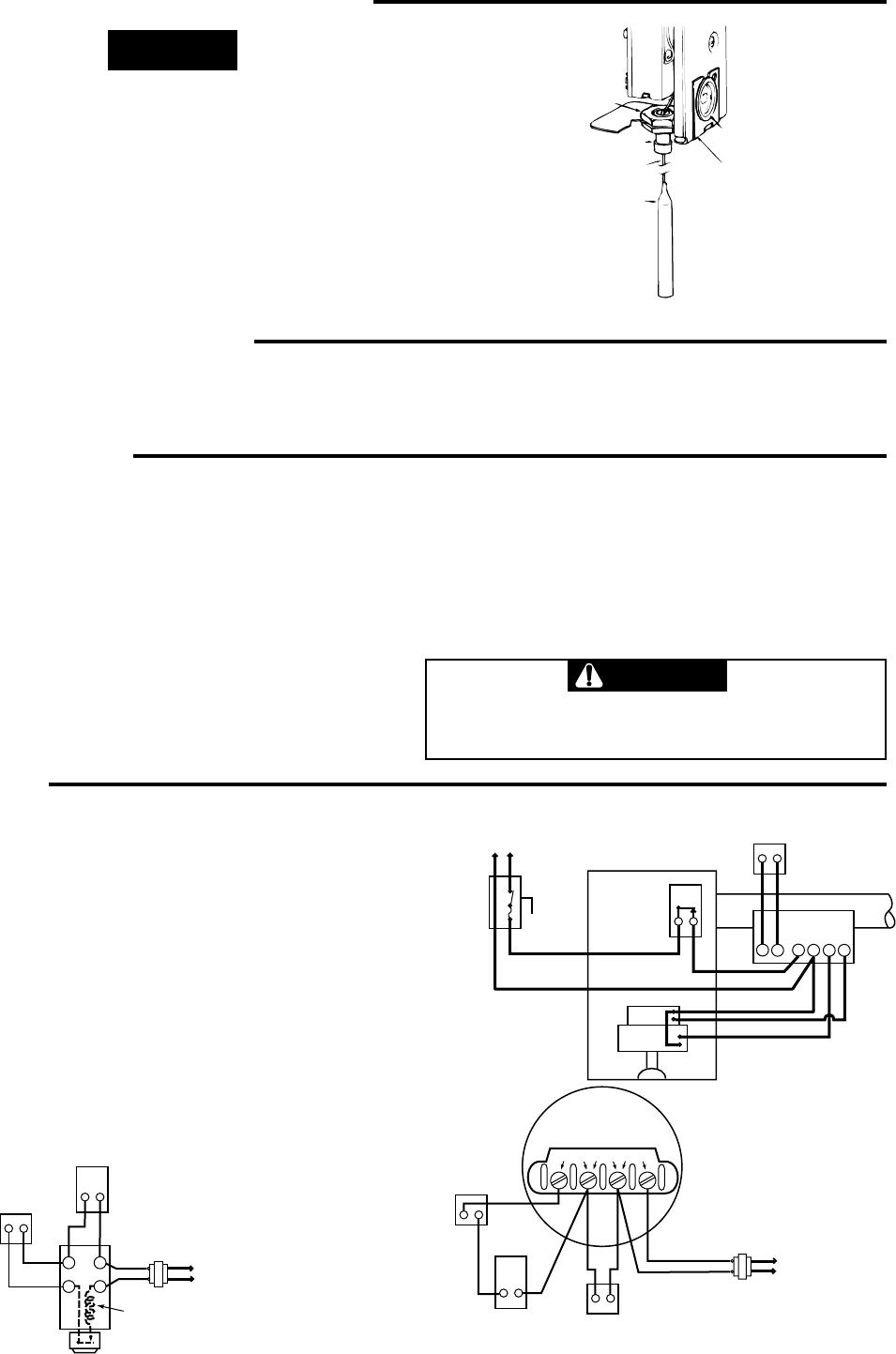

To convert from Vertical to Horizontal model, remove

Knockout Plug and Plate. Remove Hex Nut (inside con-

trol) and swing capillary upward into back knockout. Place

Knockout Plate beneath Hex Nut on back of control and

tighten Hex Nut (inside control). If bottom knockout is not

used for wiring, insert Knockout Plug.

NOTE

TRANSFORMER

TO

LINE

THERMOSTAT

AUTOMATIC

PILOT

THERM PILOT

TRANS

LIMIT

CONTROL

DIAPHRAGM

GAS VALVE

IF AUTOMATIC PILOT IS NOT USED,

CONNECT A JUMPER BETWEEN

THE PILOT TERMINALS

Used as high limit

control with

diaphragm gas valve

1 4

2 3

TH TR

AUX

TRANSFORMER

TO

LINE

THERMOSTAT

HIGH

LIMIT

COIL

PLUG-IN

PILOT

SILENT KNIGHT

GAS VALVE

Used as high limit control

with Silent Knight gas

valve with plug-in pilot

THERMOSTAT

TRANS

LIMIT

CONTROL

FUSED

LINE

SWITCH

Used as high limit

control with

oil burner control

MOTOR

1

2

T

T

4

3

LINE

GND HOT

STACK

INTERMITTENT IGNITION

OIL BURNER CONTROL

If the boiler or burner manufacturer recommends a wiring

diagram, then follow such recommendations.

If none is offered, these diagrams show suggested cir-

cuits.

All wiring should be done in accordance with local and national electrical codes and ordinances.

WIRING

EXTENDING CAPILLARY

Some controls have excess stored capillary which may be

extended for use with an extended shank well. Use reason-

able care when straightening and forming the capillary.

With the capillary fully extended, the bulb should slide all

the way to the end of the well.

INSTALLATION

If the boiler manufacturer recommends a control location,

follow such recommendations. If none is offered, the

following information gives suggested locations.

When used for high limit service, the control should be

installed in the riser close to the boiler, or in a boiler

tapping that is near the top or hottest section of the boiler.

If the boiler is also used to heat domestic hot water, make

sure that the high limit control is not located in the section

of the boiler that contains the heat exchanger or piping for

domestic hot water.

When used for low limit or operator service, the control

should be located near that section of the boiler that

contains the heat exchanger or piping for domestic hot

water.

To remove the well from the control, loosen the set screw

in the large nut, then slide the well off to expose the bulb.

Screw the well into the proper tapping. Slide the bulb back

into the well, making sure that the bulb enters the well as

far as it will go and tighten the set screw.

Do not dent or bend the bulb as this will prevent

it from fitting into the well properly.

CAUTION

KNOCKOUT PLATE

BULB

CAPILLARY

MOUNTING STEM

HEX NUT

KNOCKOUT PLUG

Convertible Control converted to Vertical Model.