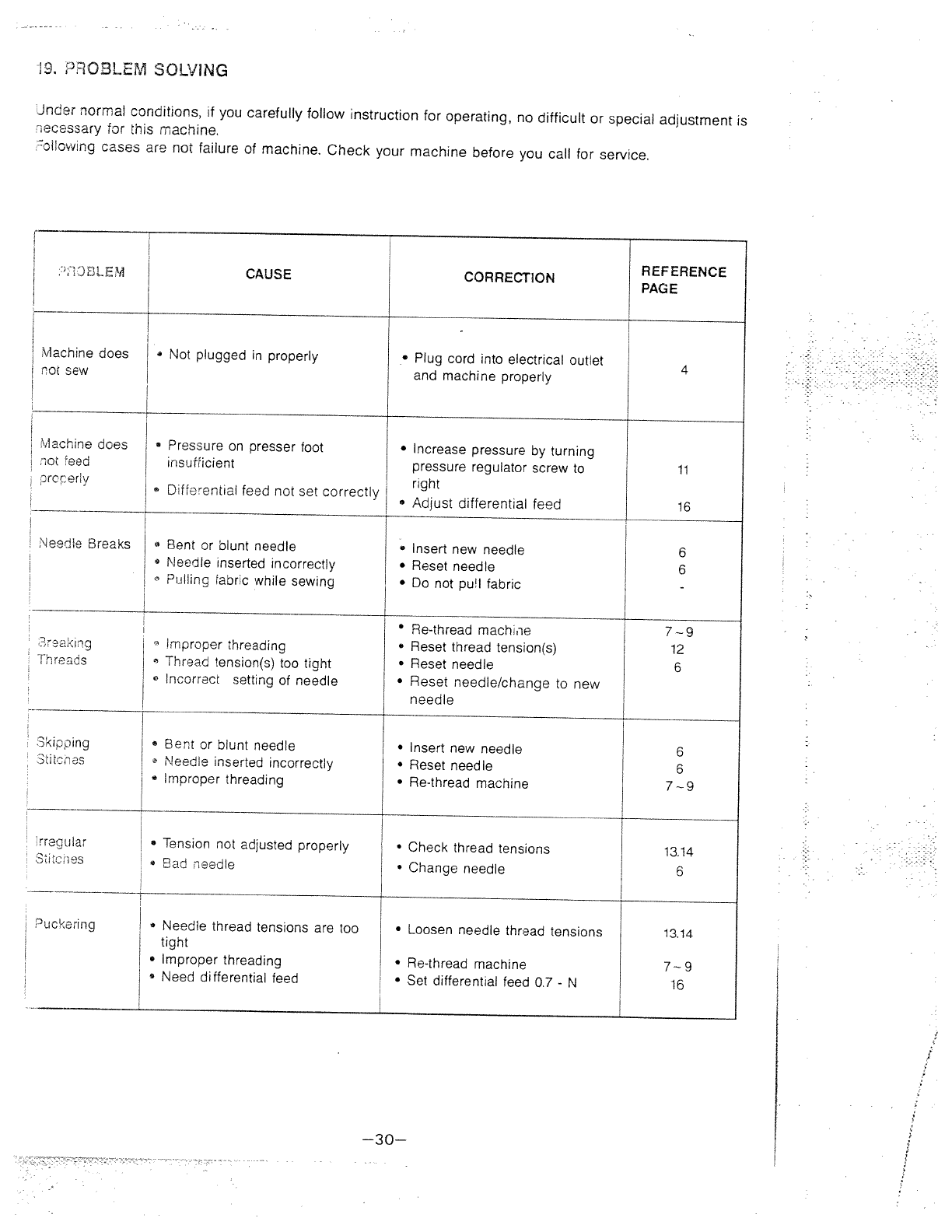

19.

PROBLEM

SOLVING

Under

normal

conditions,

if

you

carefully

follow

instruction

for

operating,

no

difficult

or

special

adjustment

is

necessary

for

this

machine.

Toliowing

cases

are

not

failure

of

machine.

Check

your

machine

before

you

call

for

service.

SQiLEM

CAUSE

CORREc11ON

REFERENCE

Machine

does

Not

plugged

in

properly

•

Plug

cord

into

electrical

outlet

not

sew

and

machine

properly

Machine

does

•

Pressure

on

presser

foot

•

Increase

pressure

by

turning

not

feed

insufficient

pressure

regulator

screw

to

11

Drccerlv

right

Differential

feed

not

set

correctly

I

•

Adlust

differential

feed

16

Needle

Breaks

Bent

or

blunt

needle

•

Insert

new

needle

6

Needle

inserted

incorrectly

•

Reset

needle

6

Pulling

fabric

while

sewing

•

Do

not

pull

fabric

-

Re-thread

machine

7—9

S-caking

improper

threading

•

Reset

thread

tension(s)

12

Threads

Thread

tension(s)

too

tight

•

Reset

needle

6

Incorrect

setting

of

needle

•

Reset

needle/change

to

new

needle

3kipping

I

•

Bent

or

blunt

needle

•

Insert

new

needle

6

Stitches

Needle

inserted

incorrectly

•

Reset

needle

6

a

Improper

threading

•

Re-thread

machine

7—9

irreaular

•

Tension

not

adjusted

properly

•

Check

thread

tensions

13.14

Stitcnes

Bad

needle

•

Change

needle

6

Puckering

•

Needle

thread

tensions

are

too

•

Loosen

needle

thread

tensions

13.14

tight

•

Improper

threading

•

Re-thread

machine

7—9

•

Need

differential

feed

•

Set

differential

feed

0.7

-

N

16

—30—