I

ROLLED

AND

NARROW

EDGE

To

carry

out

either

of

the

above

sewing

tasks

proceed

as

follows.

(1)

Refer

to

page

20

for

special

foot

position

setting.

(2)

Turn

the

handwheel

toward

you

until

needles

are

fully

raised.

(3)

Open

front

cover

and

remove

left

needle.

See

page

17.

(4)

Set

stitch

Length

between

1.0-2.0

mm.

See

page

15.

Also

ensure

that

differential

control

is

set

at

‘N’

position.

(5)

Adjust

stitch

width,as

shown

on

page

16.

(6)

If

not

already

threaded

re-thread

the

machine.

(7)

Place

fabric

under

presser

loot

and

start

to

sew.

Always

test

the

stitch

and

tension

settings

on

scrap

fabric

before

sewing

on

an

actual

garment.

When

either

Rolled

or

Narrow

hemming

we

recommend

you

change

the

threads

as

shown

on

page

22.

ALWAYS

remember

to

re-set

the

special

toot

for

normal

serging

after

you

have

finished

your

rolled

edge

procedure.

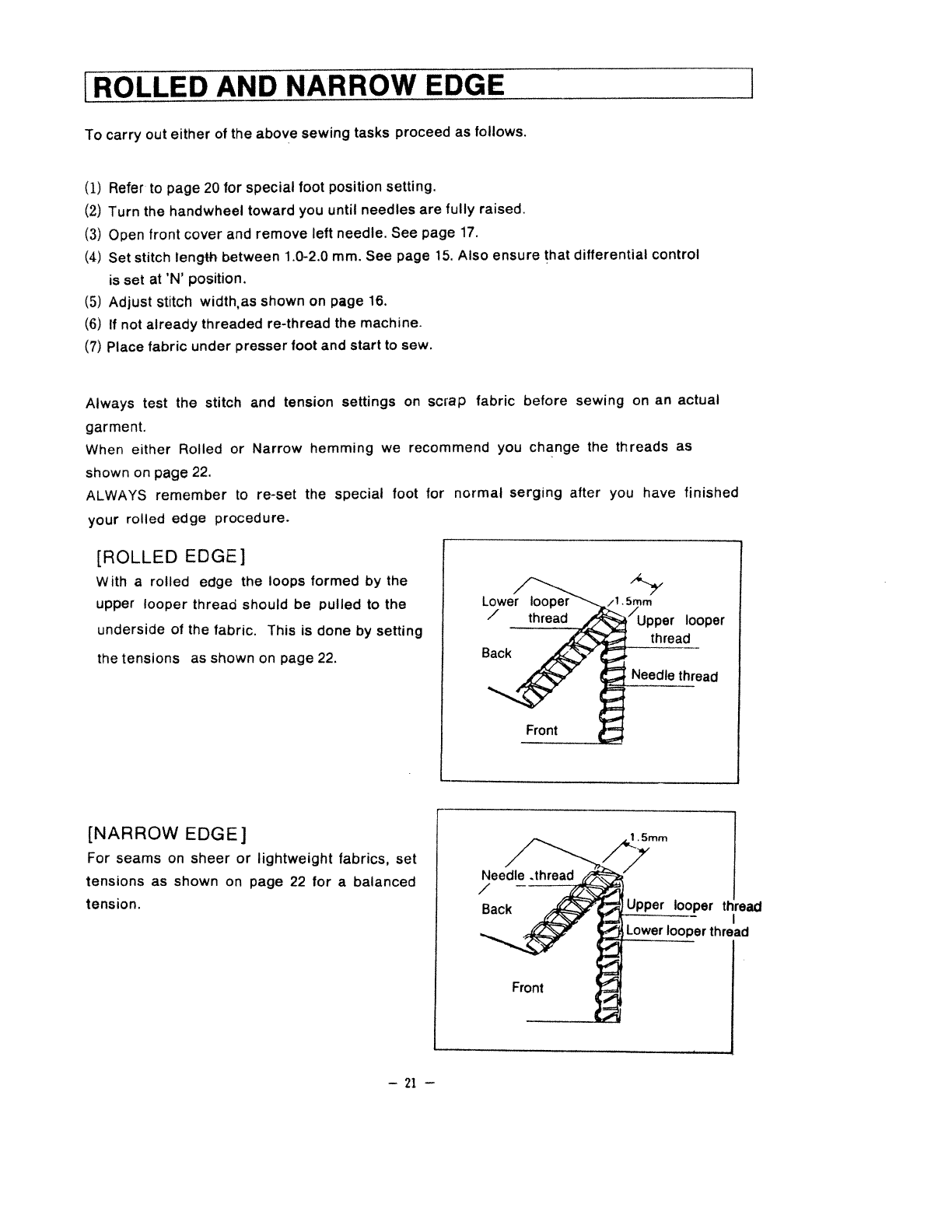

[ROLLED

EDGE]

With

a

rolled

edge

the

loops

formed

by

the

upper

looper

threao

should

be

pulled

to

the

underside

of

the

fabric.

This

is

done

by

setting

the

tensions

as

shown

on

page

22.

[NARROW

EDGE]

For

seams

on

sheer

or

lightweight

fabrics,

set

tensions

as

shown

on

page

22

for

a

balanced

tension.

—

21

—