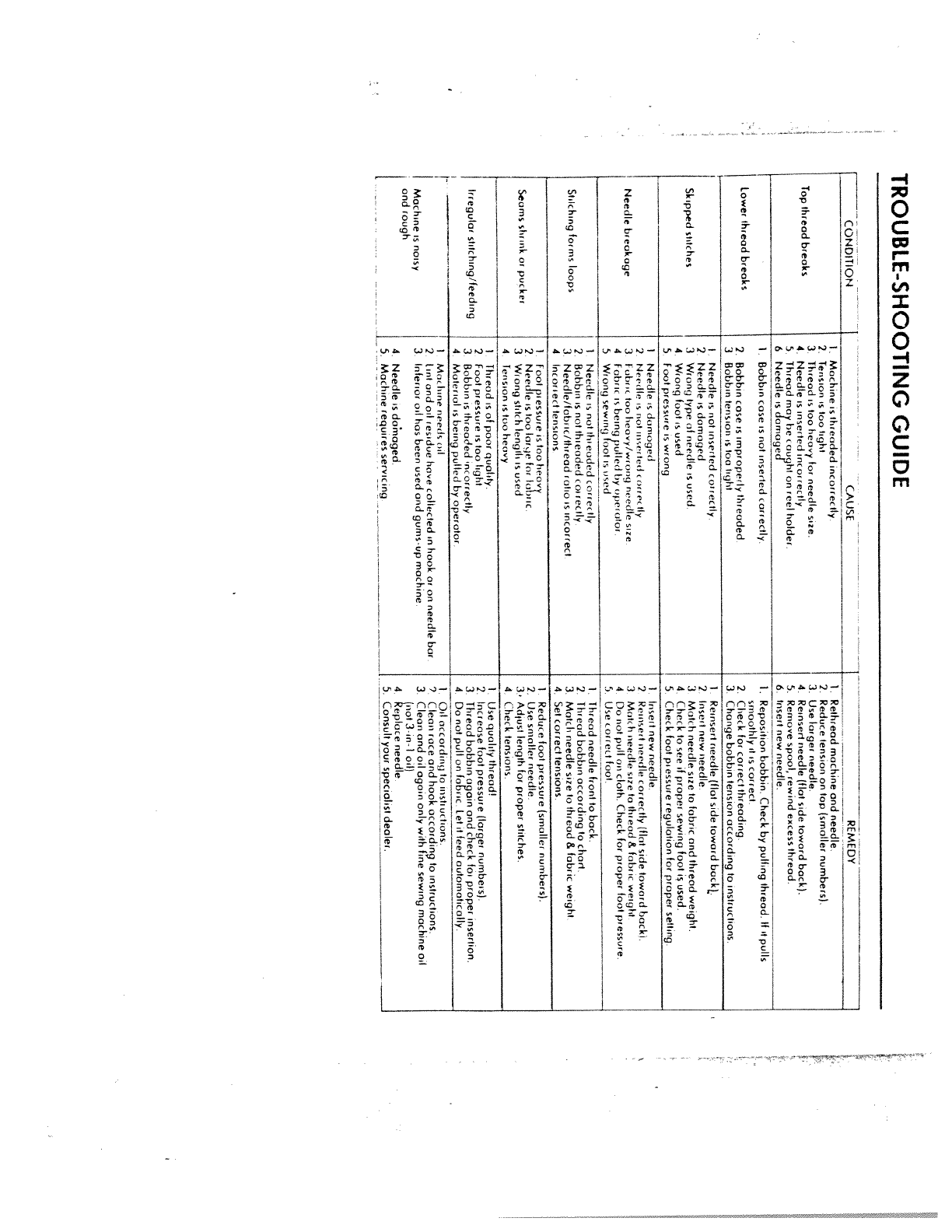

TROUBLE-SHOOTING

GUIDE

Threod

is

of

poor

quality

Fool

pressure

is

100

light

Bobbin

is

thieoc

t

ed

incorrectly

Moteiiol

is

being

pulled

by

operator

I

Mac

hint

needc

c,,l

2

tint

and

oil

residue

hose

collected

in

hook

or

on

needle

bar

3

Inferior

oil

has

been

used

and

gums-up

mochine

4

Needle

is

donaged.

5.

Maiiiine

requires

servicing

I

Use

quality

thread!

2.

Increase

foot

pressure

(lorger

numbers).

3.

Thread

bobbin

again

and

check

for

proper

insertion.

4Do

not

pull

on

fabric

Let

it

feed

automatically.

Oil

crccordi

mm

9

to

iiitr

ut

tionS

7

Clean

race

and

hook

according

to

irrstructions.

3

Clean

and

oil

again

only

with

fine

sewing

machine

oil

(rmot

3-in-!

oil)

4

Replace

needle

5.

Consult

your

specialist

deafer.

CONDITtON

CAUSE

REMEDY_________________

I

Machine

is

threaded

incorrectly.

1.

Rethreod

machine

and

needle

2.

Tension

is

too

tight

2

Reduce

tension

on

top

(smaller

numbers).

To

thread

breaks

3

Thread

is

too

heavy

for

needle

sire,

3.

Use

forger

needle

p

4.

Needle

is

inserted

incorrectly

4

Reinsert

needle

(flat

side

toward

bock).

5

Thread

may

he

caught

on

reel

holder

5.

Remove

spoof,

rewind

excess

thread

6

Needle

is

darriaged

6

tmrsertnew

needle.

I

Bobbin

case

is

riot

inseitcd

correctly

I.

Reposition

bobbin.

Check

by

pulling

thread.

If

it

pulls

Lower

thread

breaks

smoothly

it

is

correct

2

Bobbin

case

is

improperly

threaded

2

Check

for

correct

threading

3

Bobbin

tension

is

too

ighi

3

Chonge

bobbin

tension

according

to

instructions.

I

Needle

is

not

inserted

comiertly

1

Reinsert

needle

(flat

side

toward

bockL

2

Needle

is

damaged

2

Insert

new

needle

Skipped

stitches

3

Wrong

type

of

niemfle

is

used

3

Makfi

rieeille

size

to

fobrrc

nnd

threod

weight.

4

Wiong

foot

is

used

4.

Check

to

see

if

proper

sewing

foot

i

used.

5

Foot

pressure

us

wrong

5

Check

foot

pressure

regulation

for

proper

setting

1

Needle

is

dimniageil

I

ricer

t

new

needle.

2

Nreifle

is

riot

uisn-rteif

(

ommei

ly

2

Reinsert

niecifle

correctly

(flat

side

toward

bock(

Needle

break

age

3

oLin

ii

too

heavy

/

wr

on

9

niredle

size

3

Mrrk

hi

riced

Ic

size

to

thin

ecnd

&

fabr

it

weiglnt

4

F

ahr

i

is

being

I

uI

Icrl

fiy

ripen

oton

4

I)o

not

pull

nun

cloth.

C

heck

(or

proper

foot

pr

essure

S

Wi

orig

sewr

rig

foot

is

usucf

5.

lice

correct

foot

Needle

is

not

tfnn

coded

coiner

tly

1.

Tfireod

needle

front

to

back

S

h

I

I

2

Bobbin

us

not

threaded

correctly

2

Threod

bobbin

according

to

chart

or

S

OOPS

3

Needfe/fobn

it/thread

rotio

is

incorrect

3.

Match

needle

size

to

thread

&

fabric

weight

4

Incorrect

tenusicins

4.

Set

correct

tensions

foot

pressure

is

too

fiecivy

I

Reduce

foot

pressure

(smaller

rrumnnbens(.

2

Needle

is

too

lam

jr

fi

fnrlim

it

2.

Use

smaller

needle.

Seams

chink

or

pucker

3

Wiong

stitch

fengili

is

used

3

Ad

1

ust

length

for

proper

stitches

4

Tension

is

too

heavy

4(hec

k

terssnomss

Irregular

stitching/feeding

Machine

is

noisy

and

rough