7

Please note the following:

• The system should be installed only with piping that is

suitable for potable (drinkable) water such as copper,

CPVC, or polybutylene. This water heater must not be

installed using iron piping or PVC water piping.

• Use only pumps, valves, or fittings that are compatible

with potable water.

• Use only full flow ball or gate valves. The use of valves

that may cause excessive restriction to water flow is

not recommended.

• Use only 95/5 tin-antimony or other equivalent solder.

Any lead based solder must not be used.

• Piping that has been treated with chromates, boiler

seal, or other chemicals must not be used.

• Chemicals that may contaminate the potable water

supply must not be added to the piping system.

Periodic discharge of the temperature and pressure relief

valve may be due to thermal expansion in a closed water

supply system. The water utility supply meter may contain a

check valve, backflow preventer or water pressure reducing

valve. This will create a closed water system. During

the heating cycle of the water heater, the water expands

causing pressure inside the water heater to increase. This

may cause the temperature and pressure relief valve to

discharge small quantities of hot water. To prevent this, it

is recommended that a diaphragm-type expansion tank

(suitable for potable water) be installed on the cold water

supply line. The expansion tank must have a minimum

capacity of 1.5 U.S. gallons for every 50 gallons of stored

water. Contact the local water supplier or plumbing

inspector for information on other methods to control this

situation.

IMPORTANT: Do not plug or remove the temperature and

pressure relief valve.

Closed System/Thermal Expansion

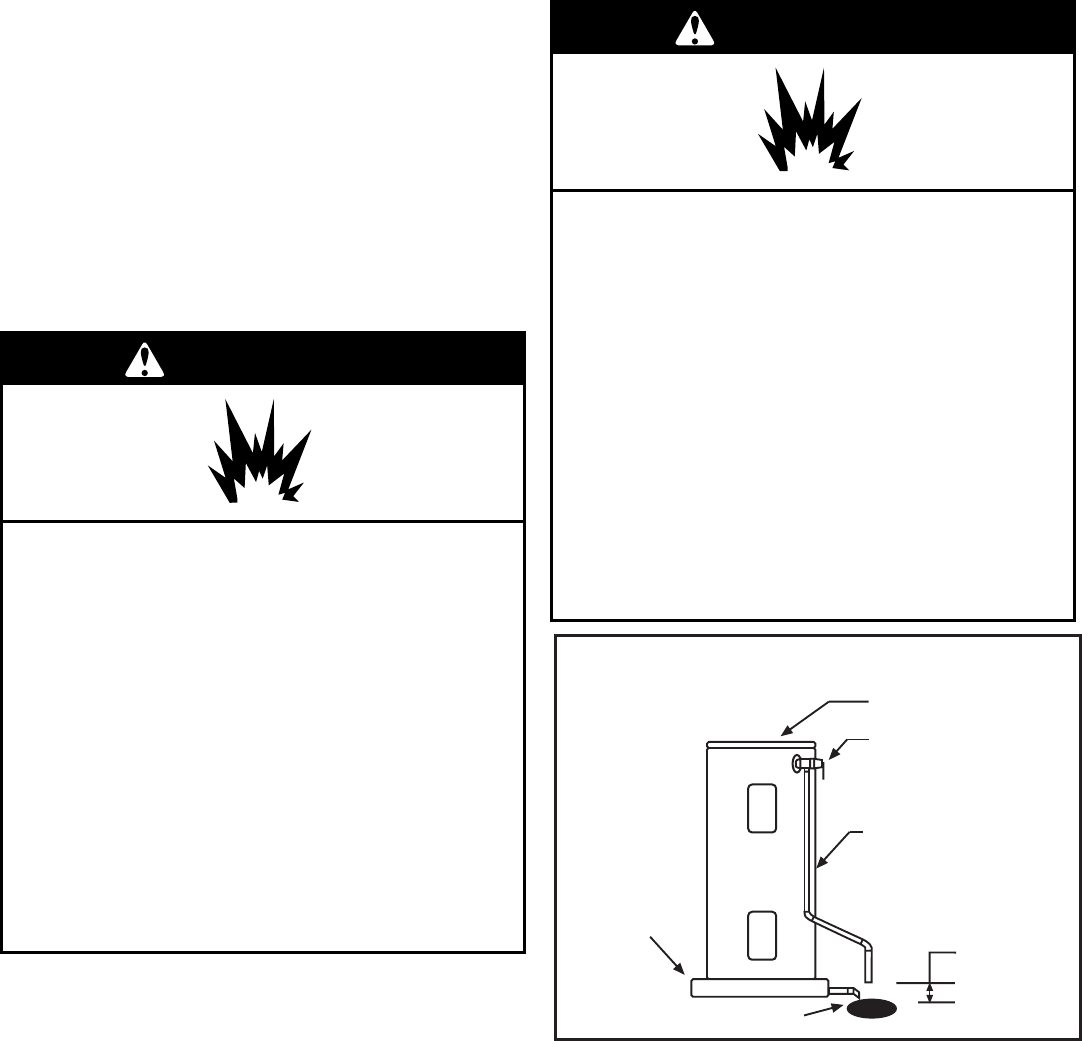

For protection against excessive pressures and

temperatures, a temperature and pressure relief valve must

be installed in the opening marked “T & P RELIEF VALVE”

(See Figure 9).

CAUTION: To reduce the risk of excessive pressures

and temperatures in this water heater, install temperature

and pressure relief protective equipment required by local

codes, but no less than a combination temperature and

pressure relief valve certifi ed by a nationally recognized

testing laboratory that maintains periodic inspection of the

production of listed equipment or materials, as meeting

the requirements for Relief Valves and Automatic Shutoff

Temperature and Pressure

Relief Valve

Figure 9

Temperature And Pressure

Relief Valve Installation

Optional Location

Some Models Only

Temperature And

Pressure Valve

Discharge Line

3/4 Inch Min.

Do Not Cap Or Plug

6 Inch

Maximum

Drain Pan

Drain

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

person replace it.

Examples of a qualified person include:

licensed plumbers, authorized gas company

personnel, and authorized service

personnel.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death or explosion.

WARNING

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

person replace it.

Examples of a qualified person include:

licensed plumbers, authorized gas company

personnel, and authorized service

personnel.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death or explosion.

WARNING