Weil-McLain 88 Water and Steam Boilers — Series 2 — For Gas, Light Oil, & Gas/Light Oil-Fired Burners

2 Part No. 550-142-023/0508

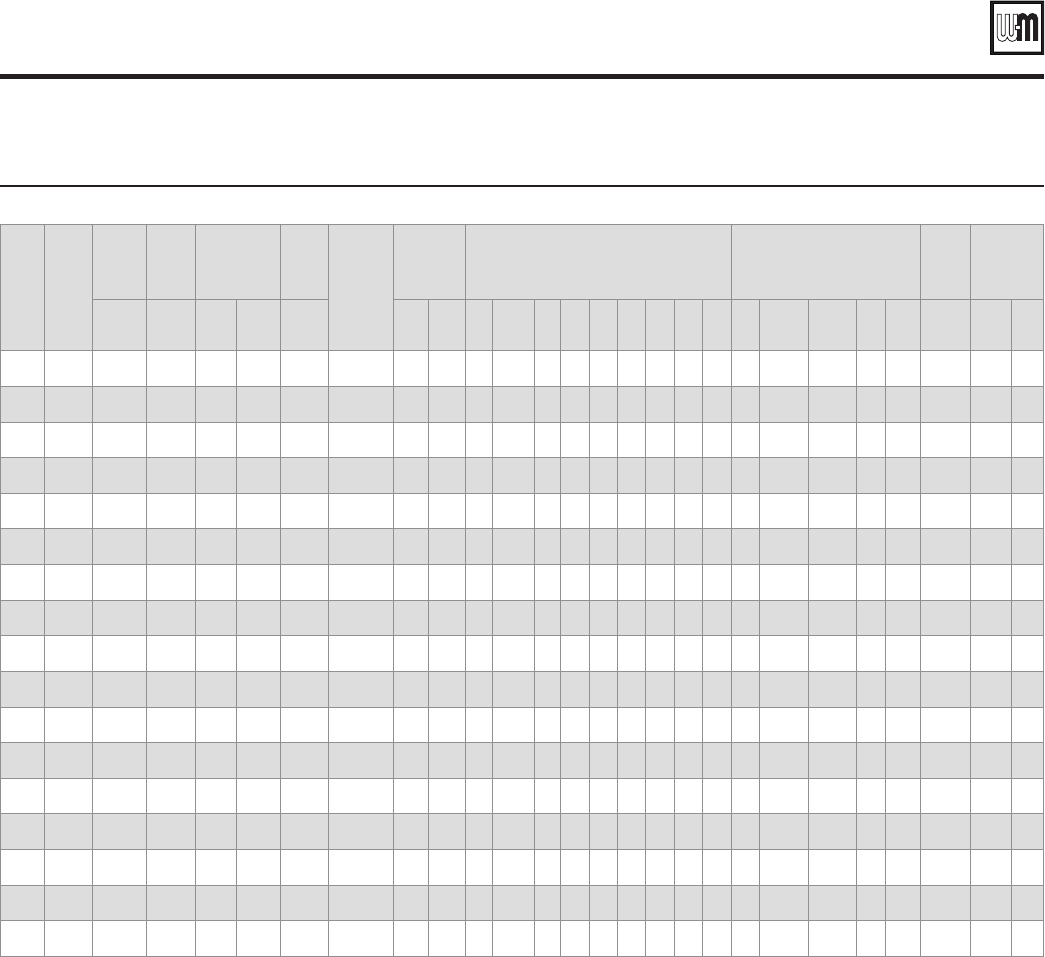

Burner data — #2 Fuel oil/Natural gas — ModulatingTable 1

Boiler

Model

Number

Burner

Model

Number

Pressure

Drop Thru

Gas Train

Manifold

Pressure

Gas Pressure

Required at

Gas Control

Inlet

Gas Pilot

Pressure

Combustion

Head

Setting

Combustion

Air

Indications

Servo Motor Cam

Position Settings

Oil

Nozzles

Oil

Pressure

Fuel

Independent

Motor Driven

3450 RPM

Inches

W.C.

Inches

W.C.

Inches

W.C.

Min

Inches

W.C.

Max

Inches

W.C.

Low

Fire

High

Fire

Blue Orange Red 1 2 3 4 5 6 Qty. GPH

@ 100

PSIG

Brand Type Spray

Angle

Supply

PSIG

Suntec

Type

Gear

GPH

488R RLS28 1.19 4.60 5.79 14 5.0 1 23 67 22 42 70 — — — — — —

1

1

2.75

2.50

Delavan B

70°

60°

180 AL65C 22.0

488 RLS28 1.19 4.85 6.04 14 5.0 2 23 67 22 42 70 — — — — — —

1

1

3.00

2.50

Delavan B

70°

60°

180 AL65C 22.0

588 RLS38 1.88 5.85 7.73 14 5.0 1 20 50 19 41 55 — — — — — —

1

1

4.00

3.50

Delavan B

60°

60°

167 AL65C 22.0

688 RLS50 2.09 5.88 7.97 14 5.0 3 32 90 32 50 90 — — — — — —

1

1

4.50

5.00

Delavan B

60°

60°

173 AL65C 22.0

788 RLS50 2.12 5.85 7.97 14 5.0 5 35 83 35 45 83 — — — — — —

1

1

5.50

6.00

Delavan B

60°

80°

168 AL65C 22.0

888 RLS70 3.04 4.36 7.40 14 7.5 0 1.5 6.0 — — — 130 0 40 120 30 100

1

1

6.50

6.50

Delavan B

90°

60°

180 AJ4CC 52.5

988R RLS70 3.18 4.14 7.32 14 7.5 0 1.8 7.5 — — — 130 0 40 120 27 100

1

1

7.50

7.25

Delavan B

90°

60°

180 AJ4CC 52.5

988 RLS70 3.18 4.39 7.57 14 7.5 1 1.8 7.5 — — — 130 0 40 120 27 100

1

1

7.50

7.50

Delavan B

60°

60°

180 AJ4CC 52.5

1088R RLS70 3.35 3.68 7.03 14 7.5 3 1.9 9.0 — — — 130 0 32 120 45 100

1

1

8.50

7.25

Delavan B

60°

60°

209 AJ4CC 52.5

1088 RLS100 3.35 3.93 7.28 14 7.5 4 1.9 9.0 — — — 130 0 32 120 45 100

1

1

8.50

7.50

Delavan B

60°

60°

209 AJ4CC 52.5

1188 RLS100 3.55 4.45 8.00 14 6.0 4 2.2 5.2 — — — 130 0 30 120 35 100

1

1

9.00

9.00

Delav

an B

60°

60°

180 AJ4CC 52.5

1288 RLS100 2.60 5.30 7.9 14 6.0 4 2.0 6.0 — — — 130 0 30 120 40 100

1

1

10.00

10.00

Delavan B

60°

60°

180 AJ4CC 52.5

1388 RLS100 3.35 4.65 8.00 14 6.0 9 2.0 6.5 — — — 130 0 30 120 40 100

1

1

11.00

11.00

Delavan B

60°

60°

200 AJ4CC 52.5

1488 RLS130 2.81 4.54 7.35 14 6.0 6 2.0 6.0 — — — 130 0 40 120 55 100

1

1

12.00

12.00

Delavan B

60°

60°

200 AJ4CC 52.5

1588 RLS130 2.99 4.65 7.64 14 5.5 7 2.5 7.0 — — — 130 0 40 120 30 100

1

1

12.00

12.00

Delavan B

60°

60°

220 AJ4CC 52.5

1688R RLS130 3.40 4.85 8.25 14 5.0 8 2.5 8.0 — — — 130 0 40 120 30 100

1

1

13.00

12.50

Delavan B

60°

60°

215 AJ4CC 52.5

1688 RLS130 3.40 5.10 8.5 14 5.0 9 2.0 9.0 — — — 130 0 50 120 30 100

1

1

13.00

13.00

Delavan B

60°

60°

215 AJ4CC 52.5

Burner specifications and settings

Notes for Table 1, Table 2 and Table 3

Burner capacities listed for elevations up to 2,000 feet. For higher eleva-1.

tions, consult local Weil-McLain distributor/ agent or sales office.

Light oil ratings based on No. 2 fuel oil with heating value of 140,000 2.

Btu per gallon.

Gas ratings based on natural gas with heating value of 1,000 Btu per cubic 3.

foot and specific gravity of 0.60. Gas burners for other gases are available.

Consult local Weil-McLain distributor/agent or sales office.

Boiler-burner unit to be adjusted to achieve +0.10 inches W.C. pressure at 4.

the flue collar, resulting in positive pressure in firebox as listed.

Minimum gas pressures listed are subject to variations due to job condi-5.

tions. Gas burners for other gas pressures are available. Consult local

Weil-McLain distributor/agent or sales office.

All gas train sizes shown are based on a supply pressure to the regulator of 6.

7 inches w.c. Optional trains available for other pressures upon request.

All Settings and pressures shown are for initial start-up. Final values should 7.

be confirmed with combustion analysis.

Gas/Light Oil control Systems: 8.

LHL: Low-high-low-off firing conditions – two position air and fuel •

controlled by separate motor, open damper pre-purge.

MOD: On-off operation with proven low fire start and full modu-•

lating firing conditions. Proportional motor drives fuel metering

valve and combustion air damper according to firing conditions;

open damper pre-purge.

120/60/1 control circuit is used for all burners.9.

All 3 phase models require a separate 12/60/1 control voltage supply.10.

Burner settings shown are for initial start-up. Follow burner manual to 11.

adjust burner using combustion test instruments as directed.

120/60/1 control circuit is used for all burners.12.

488R to 788 units require a single SPDT controller for LHL firing rate 13.

operation on both fuels.

888 to 1688 units require a 4 – 20mA 0 – 10vdc or 135 ohm signal for 14.

modulation on gas plus a SPDT controller for LHL firing rate operation

on oil.

Motor relay or contactor is standard on all units.15.

Combustion Controls:16.

Siemens LFL 1.335 flame safeguard control monitors the oil or gas •

burner flame with visual diagnostic window, provides pre-purge and

post purge, provides switching necessary to allow firing rate motor to