13

Part Number 550-110-031/0605

Control Supplement — Standing Pilot Boilers

Troubleshooting

Verify proper operation after servicing

Never jumper (bypass) any device except for momentary

testing as outlined in troubleshooting chart below.

Substantial property damage and/or severe personal

injury could occur.

Burner access panel must be in position during boiler

operation to prevent momentary flame rollout on

ignition of main flame. Severe personal injury or

substantial property damage will result.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation leading to severe personal injury,

death or substantial property damage.

Before troubleshooting:

1. Have a voltmeter that can check 120VAC, 24VAC, and a continuity tester.

2. Check for 120VAC (minimum 102 to maximum 132) to boiler.

3. Be sure pilot is lit. See “Lighting instructions” on page 12 for details.

4. Make sure thermostat is calling for heat and contacts (including

appropriate zone controls) are closed. Check for 24VAC between

thermostat wire nuts and ground.

Pilot does not stay lit —

Troubleshooting thermopile and high

limit control circuit

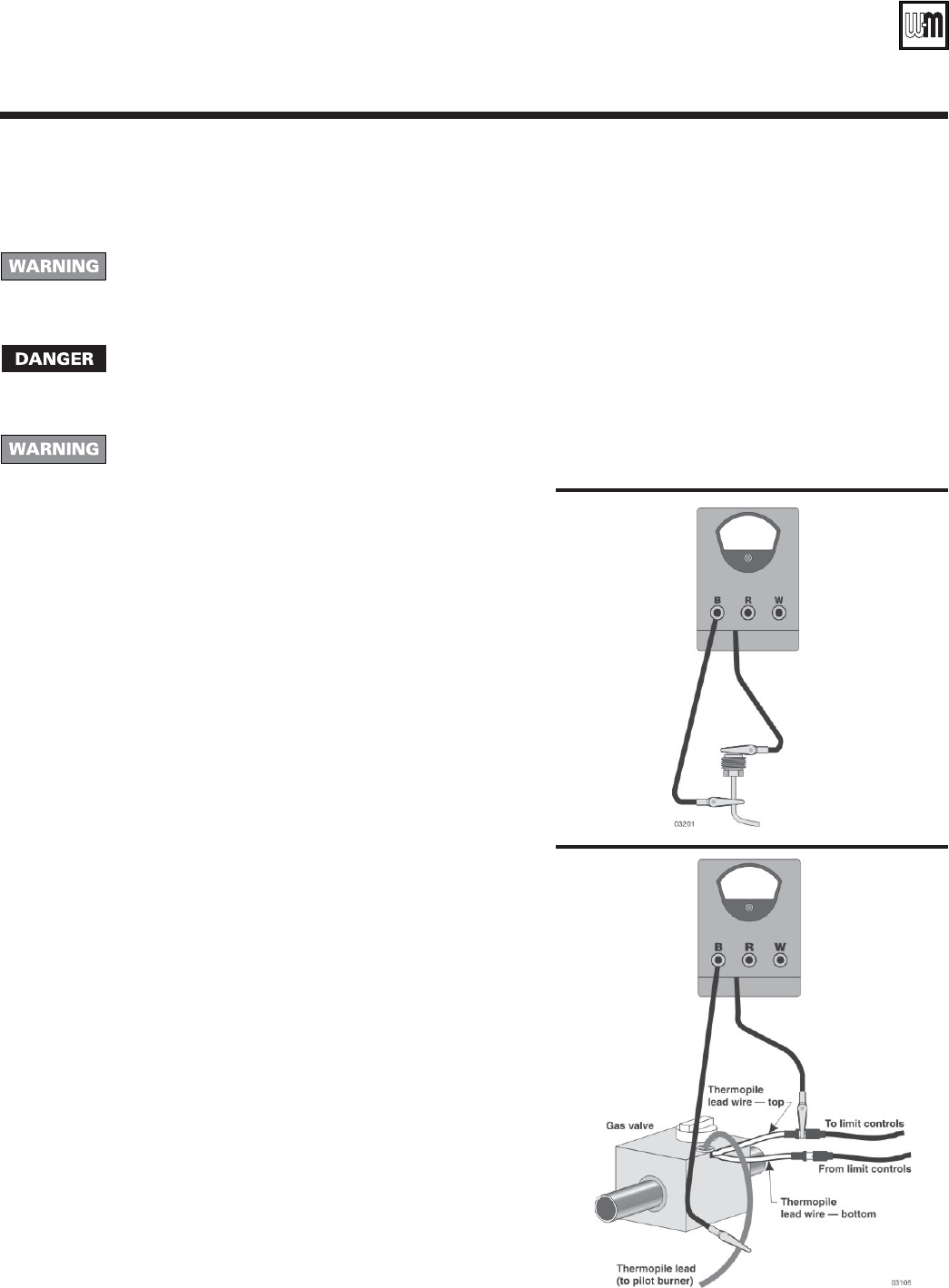

1. Checking thermopile open system (Figure 5):

a. Use an electronic multimeter, with leads fitted with alligator clips. Set

meter scale to DC Millivolts.

b. Unscrew thermopile fitting from gas valve.

c. Attach one meter lead to the end of the thermopile gas valve fitting.

d. Attach other meter lead to thermopile lead (copper surface).

e. Follow Lighting Instruction label on boiler (also found in Control

Supplement or User’s Information manual) to light the pilot burner

only and hold the pilot flame manually. (DO NOT light main burner.)

f. Check the reading on the multimeter. The reading should be around

700 millivolts.

g. If multimeter reading is significantly less than above, replace the

thermopile.

2. Checking thermopile circuit closed system (Figure 6):

a. Use an electronic multimeter, with leads fitted with alligator clips. Set

meter scale to DC Millivolts.

b. Loosen the insulated terminal on the TOP thermopile lead wire

enough to allow clipping a multimeter alligator clip to the spade

terminal.

c. Attach the other multimeter lead to the thermopile lead.

d. Check the reading on the multimeter. The reading should be around

400 millivolts.

e. If reading is significantly less than 400 millivolts, check tightness of

lead wire assembly in gas valve. If the connections are secure and you

Figure 5

Figure 6

have checked the thermopile per step 1 above,

replace the thermopile lead wire assembly.

f. If reading on TOP thermopile lead wire is around

400 millivolts, move the multimeter alligator clip

to the BOTTOM thermopile lead wire terminal

and check multimeter reading.

g. If multimeter does not read around 400 millivolts,

check wiring connections and wire integrity to

the limit controls.

h. Check voltage at each limit terminal to make sure

limit is closed. Correct pressure or temperature

condition causing any limit to be open. Replace

limit if necessary.