13

Part Number 550-110-032/0607

Standing Pilot Boilers — Control Supplement

Damper installation continued

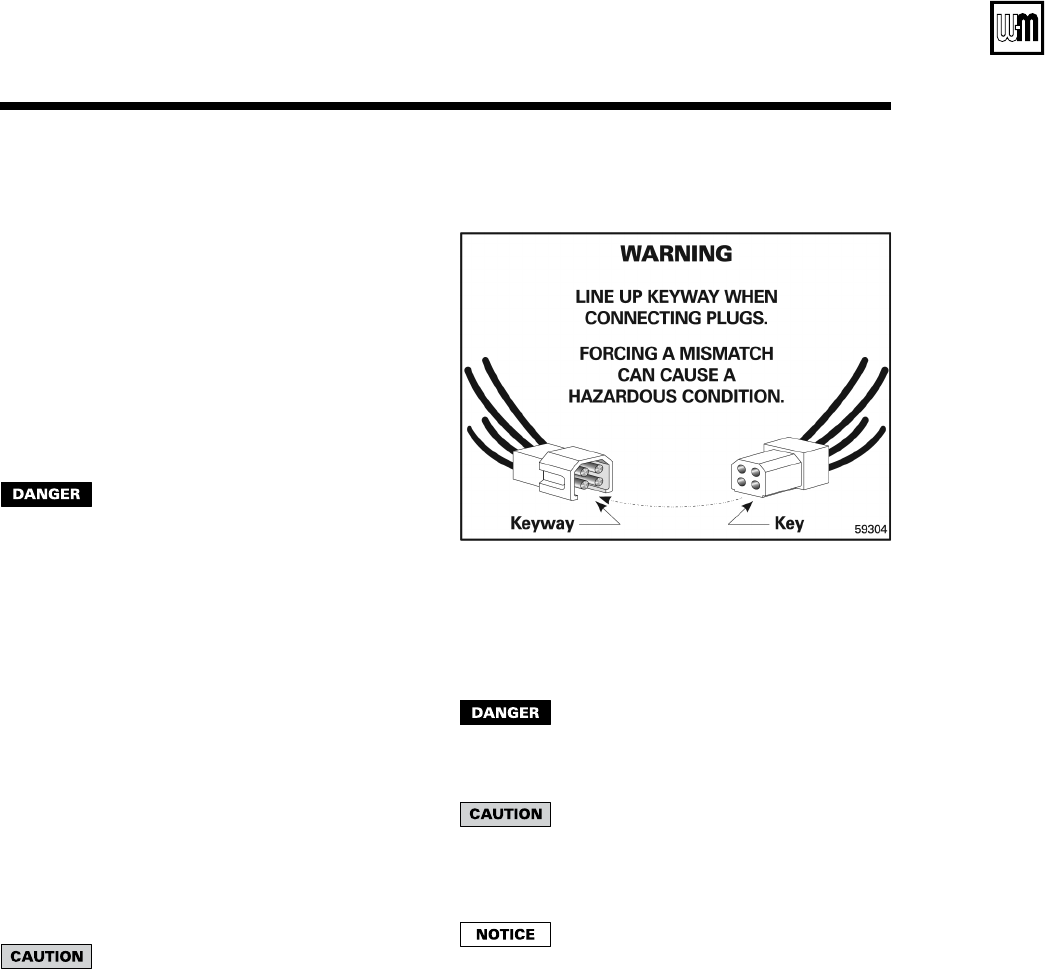

4. Read and apply the harness plug warning label

(shown above) so that it is visible after installa-

tion.

5. Plug damper harness receptacle into damper harness

plug.

Bypassing (jumpering) vent damper will

cause flue products such as carbon mon-

oxide to escape into the house. This will

cause severe personal injury or death.

After boiler has operated once, if either

end of the harness is disconnected, the

system safety shutdown will occur. The

boiler will not operate until harness is

reconnected.

Effikal damper — Damper hold open

switch must be in “Automatic Operation”

position for system to operate properly.

Minimum clearances to

combustibles

Provide a minimum of 6” between the vent damper

and any combustible material. (Provide a minimum of

46” between jacket top and combustible ceiling.) See

EG • PEG • EGH Boiler manual for complete clearance

requirements.

Installation

Do not modify draft hood or damper, or

make another connection between draft

hood and damper or boiler except as not-

ed below. This will void CSA certification

and will not be covered by Weil-McLain

warranty. Any changes will cause severe

personal injury, death, or substantial

property damage.

1. Install vent damper horizontally or vertically as

shown in vent damper manufacturer’s instructions.

Vent damper must be installed so that it serves only

one boiler and so damper blade indicator is visible

to the user. See Figure 8.

2. Screws or rivets used to secure the vent damper to

the draft hood must not interfere with rotation of

the damper blade.

3. Install damper harness between damper actuator

and knockout in jacket top panel. Use strain relief

connectors and locknuts to secure both ends of the

damper harness.

Keep wiring harness clear of all hot sur-

faces.