4

www.waynepumps.com

Operating Instructions and Parts Manual Deep Well Submersible Pump

Installation

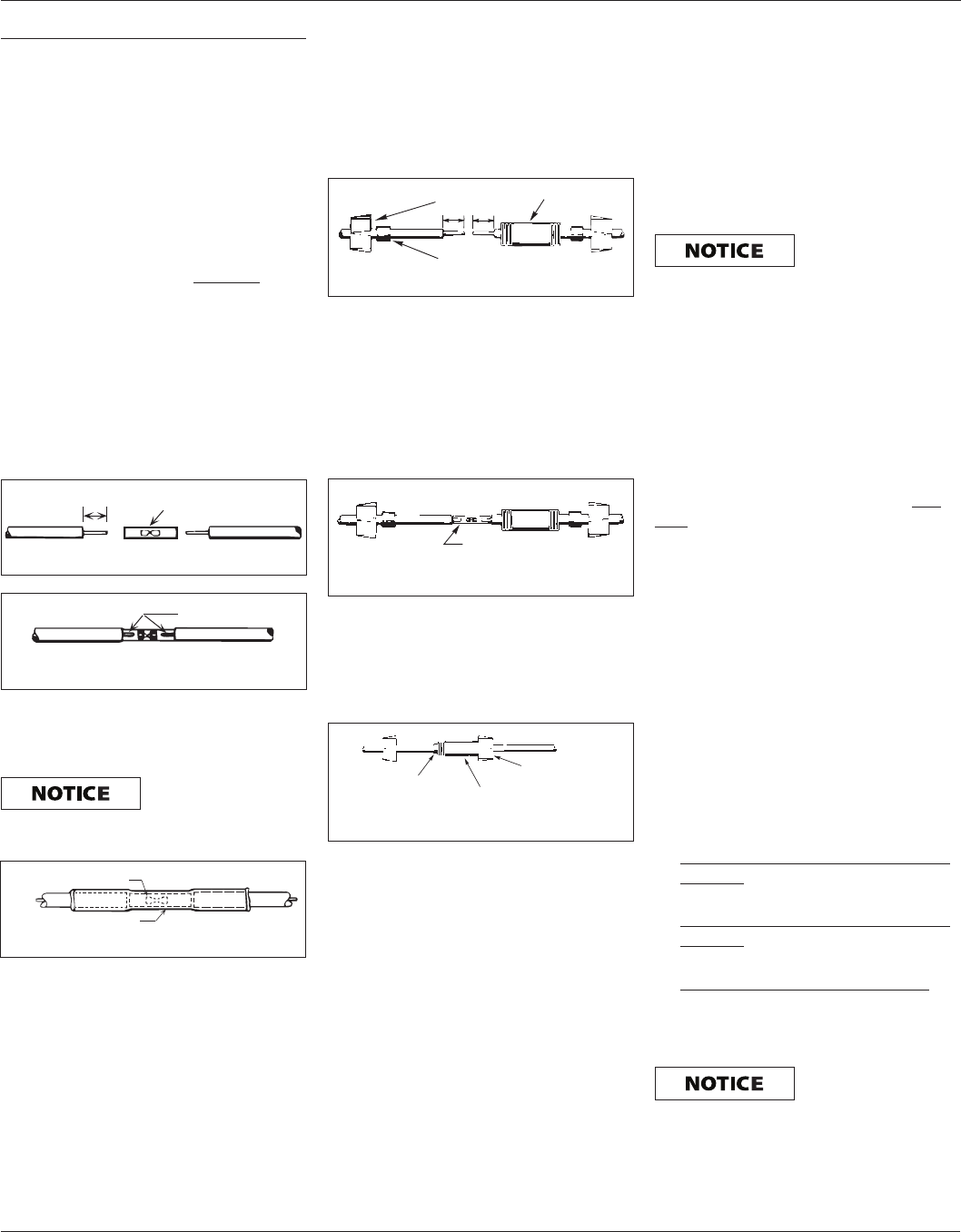

WIRE SPLICING

Splice wire to motor leads. Use only

copper wire for connections to pump/

motor assembly and control box.

Heat shrink splice instructions (wire sizes

No. 14, 12 and 10 AWG [2, 3 and 5mm

2

]):

1. Remove 3/8" (9.5 mm) insulation

from ends of motor leads and power

supply wires.

2. Place heat shrink tubing over motor

leads. Position tubing between

power supply and motor.

3. Match colors of supply wires with

colors of motor leads.

4. Insert supply wire and lead ends

into butt connector and crimp (see

Figures 2 and 3). Match colors of

supply wires with colors of motor

leads. Check lead connections by

gently pulling on them.

5. Center tubing over butt connector

and apply heat evenly with torch

(match or lighter will not supply

enough heat).

Keep torch moving.

Too much

concentrated heat MAY damage tubing

(see Figure 4).

Instructions for mechanical splice kit

with plastic insulators (wire sizes 14, 12,

and 10 AWG [2, 3, and 5 mm

2

]):

1. With wire cutting tool, cut off motor

leads. Stagger lead and wire length

so that second lead is 4" (101.6 mm)

longer than first lead and third lead

is 4" (101.6 mm) longer than second.

2. With wire cutting tool, cut off wire

ends. Match colors and lengths of

wires between power supply and

motor.

3. With wire stripping tool, trim

insulation back 1/2" (12.7 mm) from

power supply wire and motor lead

ends.

4. Unscrew plastic caps from insulators.

Place a cap and neoprene gasket

sleeve on each wire to be spliced

(see Figure 5).

5. Slide insulator body onto one wire

end (Figure 5).

6. Insert wire end into butt connector

and crimp. Match wire colors

between power supply and

motor (see Figure 6). Check lead

connections by gently pulling on

them.

7. Center insulator body over splice

and slide gasket sleeves into body as

far as they will go. Screw caps onto

insulator body (Figure 7) and tighten

by hand for a strong, waterproof

splice.

POWER SUPPLY WIRE INSTALLATION

1. To test pump, connect it to proper

power supply for a short amount

of time (no more than 30 seconds).

Power supply frequency and

voltage must be within 10% of

frequency and voltage shown on

product nameplate.

2. Fasten power supply wire leads to

pump discharge block. Then fasten

leads to plastic pipe within 6"

(150 mm) of discharge block. Use

centering guides to prevent wire

and pipe from rubbing well casing.

3. Connect copper grounding wire

to motor bracket. Grounding wire

must have a diameter at least that

of wires supplying current to motor.

Consult National Electrical Code, as

well as local code, for grounding

information and safety guidelines.

4. Use only submersible power

supply wires supplied by pump

manufacturer. When lowering

pump into well, secure supply wires

to discharge pipe at 10 ft. (3,1 m)

intervals with #33 electrical tape.

Take care not to damage pump

wires.

To avoid dropping

pump down well or

damaging wires or splices, NEVER allow

pump wires to support weight of pump.

PUMP INSTALLATION

1. If standard air-over-water pressure

tank is used, install two bleeder

orifices about 2 ft. (0.6 m) apart

as shown in Figure 10, on page 6.

Orifices will automatically charge the

tank with air. See Figure 10 to help

determine orifice location.

NOTE: If precharged tank is used, DO

NOT install bleeder orifices. If pump

and pre-charged tank are replacing a

standard tank system, remove bleeder

orifices before installing pump in well.

2. To prevent losing pump down the

well, connect safety rope strong

enough to support pump and drop

pipe (minimum 5/16" [8 mm] twisted

polypropylene or pronila rope) to

eyelet on pump discharge. Tie off

other end of safety rope securely to

well seal, well cap or pitless adapter.

NOTE: Discharge outlet is 1-1/2" NPT

threaded.

3. Install piping based on these

guidelines:

For installations up to 100’ (30.5 m)

in depth, use 100 psi (689.5 kPa)

rated polyethylene plastic pipe.

For installations up to 220’ (67.1 m)

in depth, use 160 psi (1103.2 kPa)

rated polyethylene plastic.

For depths beyond 220’ (67.1 m),

use galvanized steel pipe for the

entire drop pipe.

INITIAL STARTUP/NEW WELLS

NEVER operate

pump with

discharge valve completely closed. This

CAN cause significant pump damage

and WILL void the warranty.

1/2 inch

(12.7mm)

BUTT CONNECTOR

Figure 2

INDENT HERE

Figure 3

CONNECTOR

HEAT SHRINK TUBING

Figure 4

END CAP

GASKET

INSULATOR BODY

1"

2

1"

2

12.7mm 12.7mm

Figure 5 - Ready to splice

BUTT CONNECTOR OR

CRIMP OR SOLDER

Figure 6 - Wire ends spliced

INSULATOR BODY

CENTERED OVER SPLICE

GASKET SLEEVE IN PLACE

CAP SCREWED ON

Figure 7 - Tighten end caps