4

www.waynepumps.com

2. With the cover removed, add water

to the basin and observe the float

control switch operation.

3. Also, test alarm switch if installed.

4. Secure and seal basin cover.

Do not run your pump in a dry sump.

Do not attempt to

oil the motor. A

special oil has been put in the motor

housing at the factory. Use of any other

oil could damage the pump and WILL

void the warranty.

Maintenance

Always disconnect

the electrical

supply before attempting to install,

service, relocate or perform any

maintenance. If the power source is out

of sight, lock and tag in the open (off)

position to prevent unexpected power

application. Failure to do so could result

in fatal electrical shock. Only qualifi ed

electricians should repair this unit.

Improper repair could result in fatal

electrical shock.

1. Let the pump cool for a minimum of

two hours before servicing because

the pump contains hot oil under

pressure and the motor is hot.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

3. Inlet should be kept clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

4. Pump should be checked monthly

for proper operation.

This pump contains

dielectric oil for

cooling. This oil can be harmful to

the environment. Check the state

environmental laws before disposing

this oil.

Operating Instructions and Parts Manual

Operation (Continued)

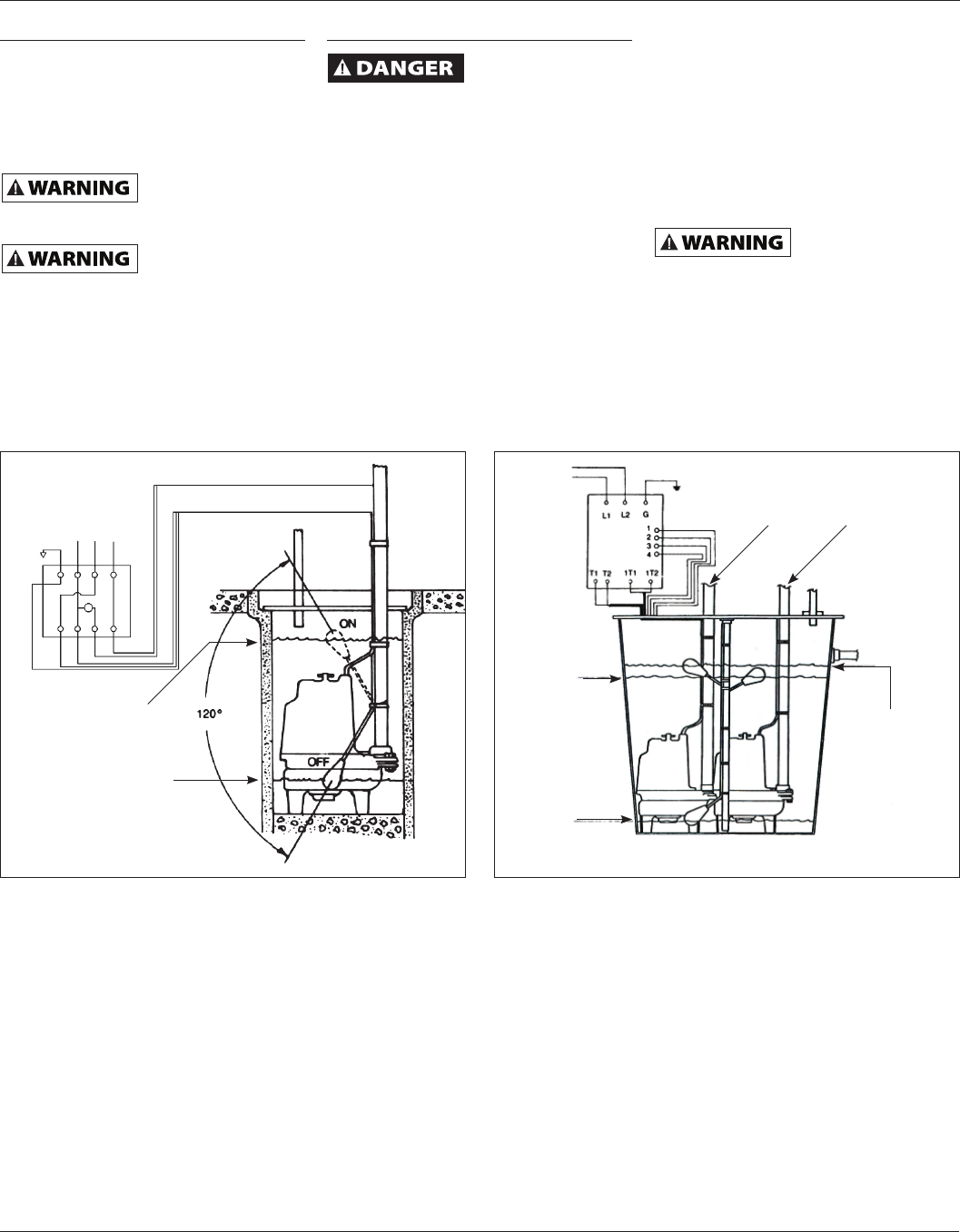

Figure 6 - Duplex System

Off Level

On Level

Alarm

Level

Pump #1

Discharge

Pump #2

Discharge

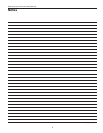

Figure 5 - Simplex System

High Water Level

Low Water Level