8

After the piping and meter have been checked completely, purge the system of air. Do not bleed the air inside the furnace.

Be sure to relight all the gas pilots on other appliances.

PURGING

After the piping has been checked, all piping and appliances receiving gas through the meter shall be fully purged. A

suggested method for purging th gas line to the burner is to disconnect the pilot line at the outlet o the pilot valve. Under no

circumstances shall th line be purged into the combustion chamber.

After th e gad line to the conversion burner has been fully purged and the pilot line reconnected, the gas supply at other pilot

burners located on other gas appliances which were extinguished as the result of interrupted service shall be reignited.

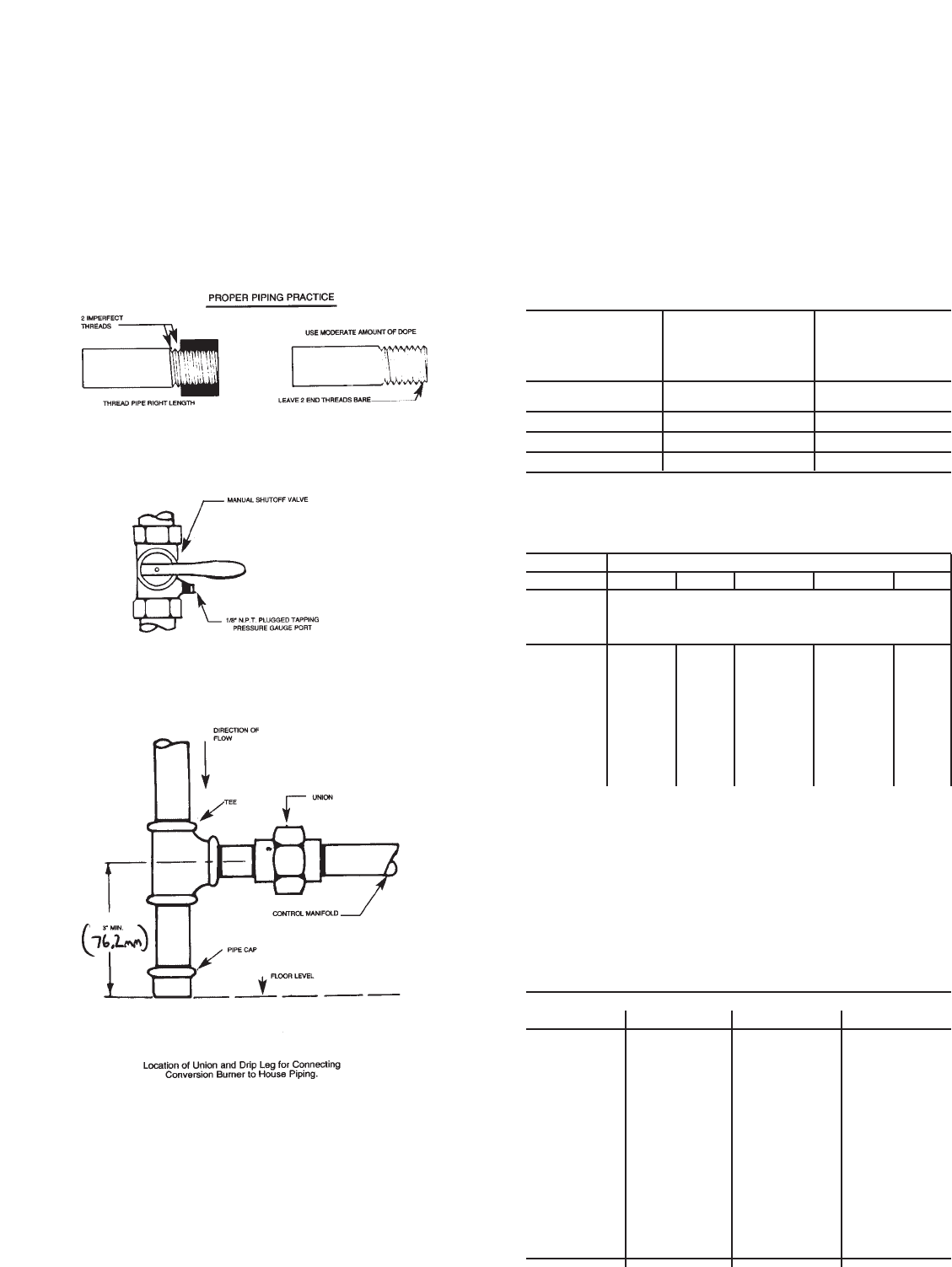

LENGTH OF STANDARD PIPE THREADS inches (mm)

EFFECTIVE OVERALL

PIPE SIZE LENGTH LENGTH

OF THREAD OF THREAD

3/8 (9.525) 3/8 (9.525) 9/16 (14.29)

1/2 (12.7) 1/2 (12.7) 3/4 (19.05)

3/4 (19.05) 1/2 - 9/16 (14.29) 13/16 (20.64)

1 (25.4) 9/16 (14.29) 1 (25.4)

PIPE CAPACITY TABLE

Nominal Diameter of Pipe in Inches

3/4 (19.05) 1(25.4) 1-1/4 (31.75) 1-1/2 (38.1) 2 (50.8)

Length

of Pipe Capacity - Cu, Ft. Per Hr. with a 0.6

in Feet Sp. Gr. Gas and Press. Drop of 0.3 In. (74.72 Pa) Water Col.

15 (4.572) 172 345 750

30 (9.144) 120 241 535 850

45 (13.72) 99 199 435 700

60 (18.29) 86 173 380 610

75 (22.86) 77 155 345 545

105 (32) 65 131 285 450 920

120 (36.58) 120 270 420 860

180 (54.86) 100 225 350 720

FIGURE 8

To convert the figures given above to capacities for another

gas of different specific gravity, multiply the tabular values by

the multiplier shown below.

MULTIPLIER FOR VARIOUS

SPECIFIC GRAVITIES

SPECIFIC SPECIFIC

GRAVITY MULTIPLIER GRAVITY MULTIPLIER

.35 1.31 1.00 .775

.40 1.23 1.10 .740

.45 1.16 1.20 .707

.50 1.10 1.30 .680

.55 1.04 1.40 .655

.60 1.00 1.50 .633

.65 .962 1.60 .612

.70 .926 1.70 .594

.75 .895 1.80 .577

.80 .867 1.90 .565

.90 .817 2.10 .535