Model ISP40

Troubleshooting Chart

Problem Possible Cause(s) Corrective Action

1.Power outage

2.Blown AC breaker

3.GFCI tripped

4.Low AC voltage

1. Pump fuse may be blown

2. Pump impeller may be

damaged

Low battery

1. Battery polarity is incorrect

2. Battery voltage too low

1. Lower float stuck

2. Pump too low in sump

1. Pump power cord

2. Upper float switch stuck

3. Impeller rotor jam

1. Backflow from discharge

pipe

2. Pump too low in sump

3. Clogged pump filter

1. Blocked discharge pipe

2. Partially clogged pump

filter

3. Broken thrust bearing

1. Discharged battery

2. Shorted cell battery

1. None

2.Push AC breaker to reset. If breaker trips again, do not reset.

Have unit checked by qualified electrician

3. Reset GFCI

4. Have outlet checked by electrician

1. Replace pump fuse. Use Bussmann AGC10 or Littlefuse 312010

2. Remove impeller. Check for damage to bore or bearing

Apply AC power or replace batteries

1. Recheck battery polarity

2. Replace batteries

1. Remove filter and clean. Remove debris from float switch area

2. Place a brick under the pump

1. Check for proper installation of power cord into the PS/BC

2. Remove filter and clean. Remove debris from float switch area

3. Remove filter and clean. Remove debris from float switch area

1. Install or replace check valve

2. Place a brick under the pump

3. Remove filter and clean

1. Check for restrictions in discharge line, flood is immanent. Shut

off AC power before entering flooded area

2. Remove impeller, check for debris in inlet

3. Remove and inspect thrust bearing

1. If the battery is in otherwise good condition, it is normal for

the circuit breaker to cycle ON and OFF several times before

the battery recovers enough to allow a normal charge rate. If

this happens on a regular basis, however, the batteries may be

too large for the PS/BC and it could be damaged. Replace

batteries

2. A battery in this condition may cause the breaker to cycle

continuously. The battery will not accept a charge. Replace

both batteries

AC Power Indicator

(red light) is not on

Alarm sounds - yellow

light is on

Alarm sounds - yellow

light is on and red

light is off

Green Light is off

Pump will not stop

Pump will not start

Pump starts/stops too

often

Pump operates but

delivers little or no

water

“Click” inside PS/BC.

An overload is

indicated when you

hear a distinct “click”

from the DC circuit

breaker internal to the

PS/BC. A 3-5 minute

cooling off period

occurs before the PS/BC

resets itself. If the

overload condition still

exists, the cycle will

repeat. Regardless of

what is causing the

circuit breaker to cycle,

unattended or routine

operation in this

manner could result in

serious damage to the

PS/BC and the battery.

www.waynepumps.com

Pump Installation

Installation may

take several hours.

Do not disable an existing sump pump

until you have established an

appropriate way to evacuate sump pit.

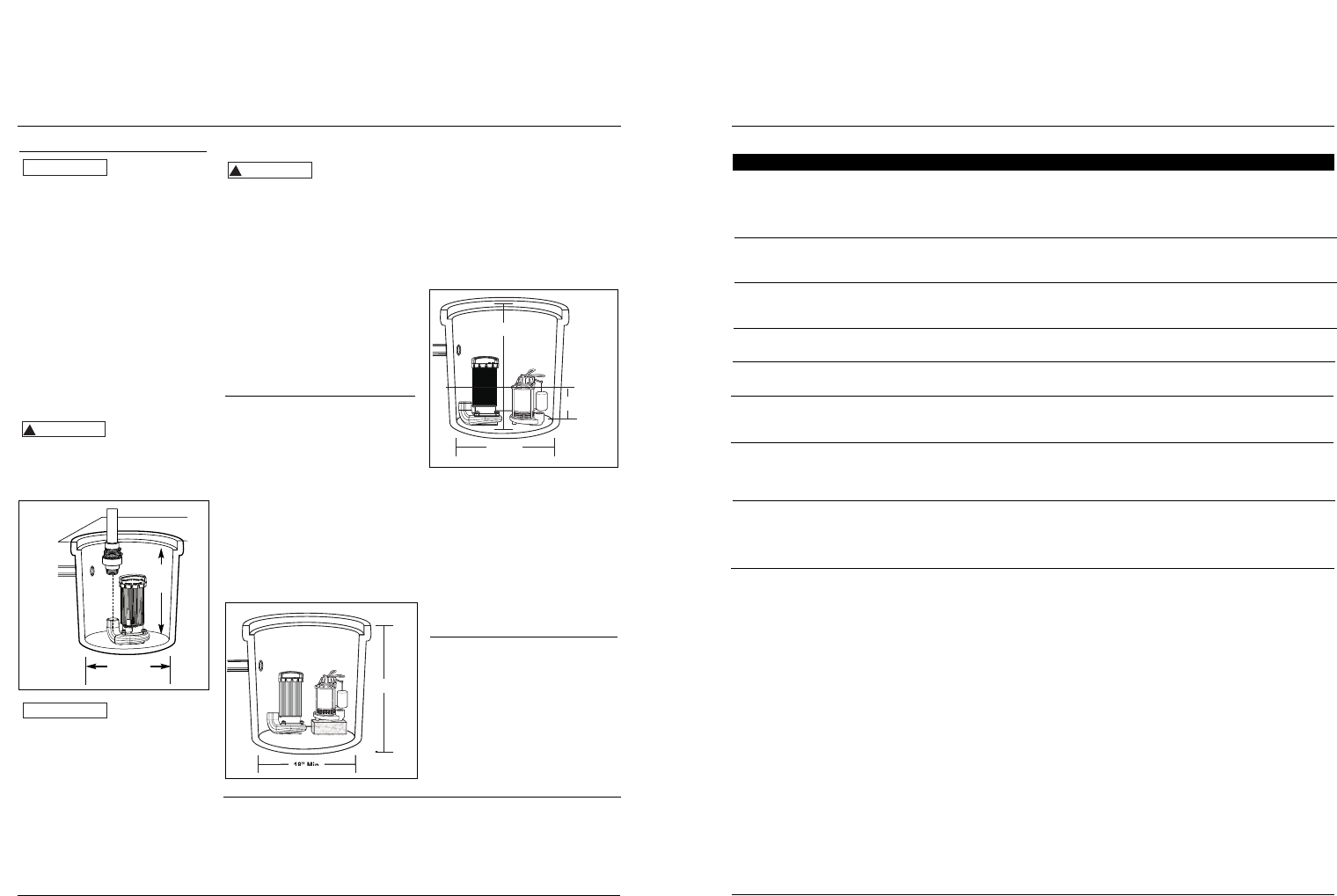

1. Install pump in a sump pit with

minimum size as shown in Figure 2.

Construct sump pit of tile, concrete,

steel or plastic. If the sump pit

already exists, disconnect power to

existing pump and make certain pit

is the correct size.

2. The sump pump should be located

on a solid, level foundation. Do not

place pump directly on clay, earth,

gravel or a sandy surface. These

surfaces contain small stones, gravel,

sand, etc. that may clog or damage

the pump and cause pump failure.

Remove any silt or debris from the

sump pit and surrounding area.

Flood risk. If

flexible discharge

hose is temporarily used, make sure

pump is secured in sump pit to prevent

movement. Failure to secure pump

could result in flooding and property

damage.

Flexible discharge

hose is intended

for temporary use only. Rigid PVC or

metal pipe is required for a permanent

installation.

3. Thread check valve (not included)

into pump body. Avoid stripping or

cross threading. Do not use pipe

joint sealant.

4. The pump has a 1-1/2” NPT discharge.

If the existing piping is smaller, use an

adapter. Smaller diameter piping will

reduce the pump flow rate and

decrease its performance. Do not

reduce below 1 1/4”.

NOTICE

!

WARNING

NOTICE

7

5. Connect rigid pipe to rubber boot on

check valve. Tighten hose clamps.

Support pump and

piping when

assembling and after installation.

Failure to do so could cause piping or

check valve to break, pump to fail, etc.,

which could result in property damage

and/or personal injury.

6. Protect electrical cord from sharp

objects, hot surfaces, oil and

chemicals. Avoid kinking the cord.

Replace a damaged cord immediately.

7. A sump pit cover must be installed to

prevent debris from clogging or

damaging the pump.

8. Fill sump with at least 6 inches of

water.

Multiple pump

systems

When installing more than one pump

in a sump it will be necessary to decide

if the AC/ DC Sump Pump will be

installed as a primary or as a back up

sump pump. The manufacturer

recommends the AC/ DC Sump Pump

be installed as a primary pump. A

conventional AC powered electrical

back up pump can be installed

alongside as shown in Figure 3. You

will need to raise the electrical back up

pump by placing it on a brick, or by

adjusting the float so that the

electrical pump turns on above the

level of the AC/ DC Sump Pump.

!

WARNING

2

Operating Instructions And Parts Manual

Operating Instructions and Parts Manual

If the AC/ DC Sump Pump is to be used

as a backup for an electrical primary

pump it is important to maintain a

minimum water level of 6 inches in the

sump when measured from the bottom

of the AC/ DC Sump Pump. The water

is needed to allow the AC/ DC Sump

Pump to go through its 24-hour testing

cycle. You will need to adjust the off

level of the Electrical Primary Pump to

turn off at the minimum water level of

6 inches as shown in Figure 4.

The on level of the Electrical Primary

Pump must turn on before the 11 inch

on point of the AC/ DC Sump Pump.

Do not raise the AC/ DC Sump Pump

above the level of the Electrical

Primary Pump.

If it is necessary to have the primary and

back up pumps discharge into a common

line, check valves will be required on

both pumps to eliminate back

reticulating flow into the inactive pump.

Battery Information

The system is designed to operate

most efficiently with sealed lead acid

(SLA) batteries at 24 volts. Two 12-volt

40-amp hour SLA batteries provide

enough energy to pump more than

10,000 gallons of water from a

basement. Deep cycle marine batteries

can also be used.

Sealed lead acid batteries cost slightly

more, but they can last longer. Wayne

offers a 40 amp hour battery, 66900-

Model ISP40

Figure 2

15”

Min.

10” Dia.

Min.

www.waynepumps.com

Amp Hours Per Battery Total Gallons Pumped*

40.0 11,000

80.0 22,000

120.0 33,000

* Assumes the sump pump is lifting water 10’

CHART 1 - STANDBY POWER PUMPING CAPACITY

18” Min.

22”

Brick

Figure 3

22”

18” Min.

Minimum

Water Level

Primary

Off Point

6”

Figure 4