Maintenance

Make

certain

that the pump is unplugged before

attempting to service or remove any

component. This pump is assembled in

the factory using special equipment;

therefore only authorized service

dealers or qualified electricians should

attempt to repair this unit. Improper

repair can cause an electrical shock

hazard.

The

pump

contains oil that may be under pressure

because of heat. Let the pump cool for

a minimum of two hours before

servicing this unit.

1. Disassembly of the motor prior to

expiration of warranty will void the

warranty. It might also cause

internal leakage and damage to the

unit. If repairs are required, return

the pump to the dealer from whom

it was purchased or call 1-800-237-

0987. If motor is ever disassembled

the o-rings must be replaced. Care

must be taken to ensure that all

seals do not leak.

2. After the basin cover is removed

and necessary discharge piping

disconnected, lift pump from basin.

3. Pump should be checked on a

regular basis for proper operation.

If anything has changed since unit

was new, the unit should be

removed and repaired or replaced.

Only qualified electricians or service

people should attempt to repair this

unit. Improper repair and/or

assembly can cause an electrical

shock hazard.

4. Place the pump in a suitable area

where it can be cleaned thoroughly.

Remove all scale and deposits on

pump.

Installation (Continued)

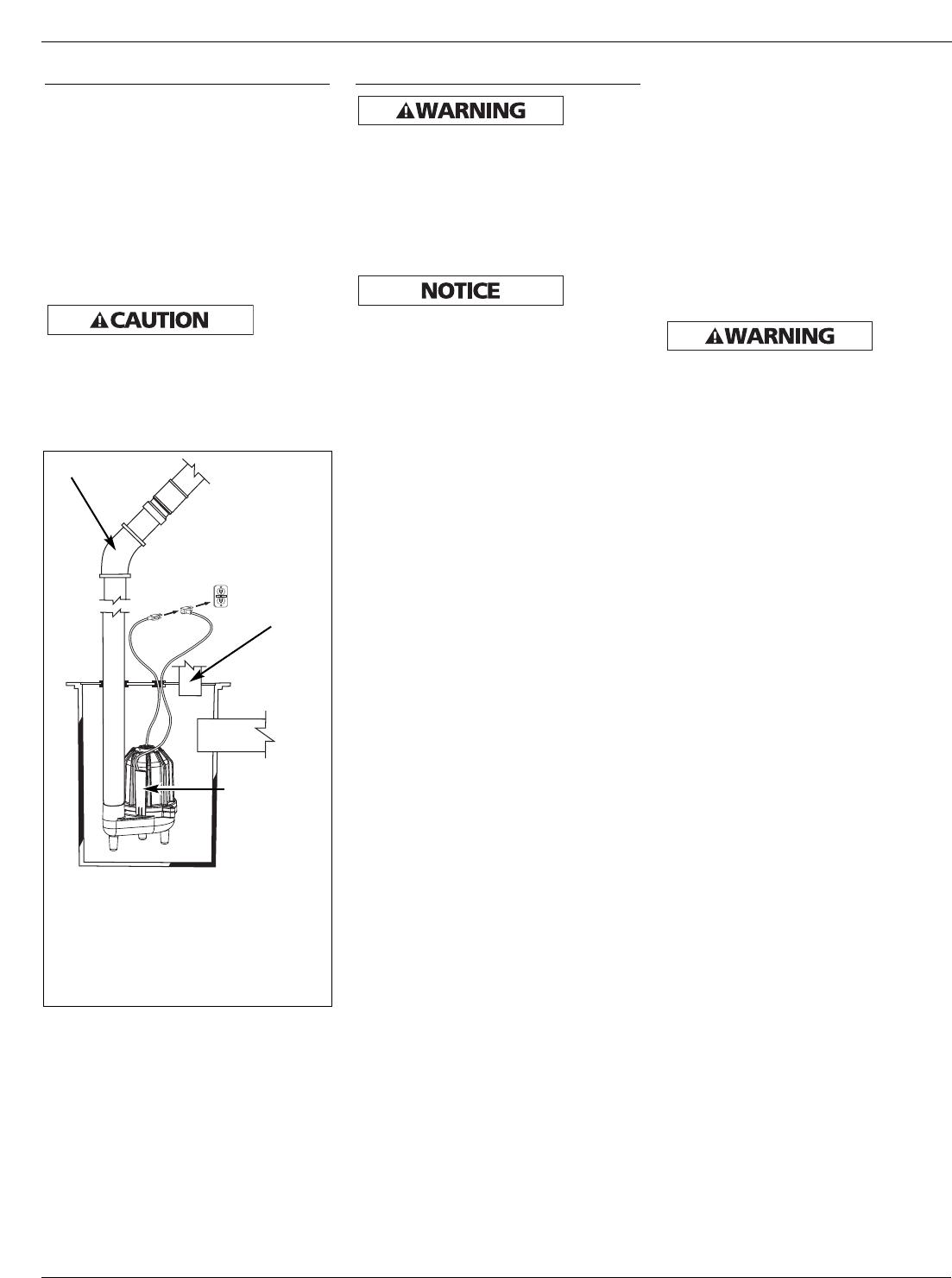

8. CSECAP40 and CSECAP50 models

are supplied with an “Switch-

Genius” capacative water sensor

(see figure 3B). Position the pump

in the basin so that the “Switch-

Genius” water sensor is 180° away

from the basin inlet. Make certain

the incoming water stream does not

hit the “Switch-Genius” water

sensor surface.

Before

removing

pump from basin for service, always

disconnect electrical power to pump

and control switch. For any work on

pump or switch, ALWAYS unplug the

power cord. Do not just turn off circuit

breaker or unscrew fuse.

4

Operating Instructions and Parts Manual

www.waynepumps.com

5. Submerge the complete pump in a

disinfectant solution (10% chlorine

bleach solution) for at least one

hour before handling the pump.

6. Clean all dirt and deposits from the

pump float. Make sure float moves

freely after cleaning (CSE50T).

7. Clean all dirt and deposits away

from pump inlet and volute.

8. Clean “Switch-Genius” water sensor

surface (models CSECAP40 and

CSECAP50).

This

pump

contains dielectric motor oil for

lubrication and motor heat transfer.

This oil can be harmful to the

environment. Check state

environmental laws before disposing of

this oil. This oil can be harmful to

aquatic life so consideration should be

exercised in the application of this

pump.

TEST RESET

Check valve 45

o

Vent

Inlet

Gasket

“Switch-

Genius”

surface *

Basin

Figure 3B - Prefabricated Basins

* Orient the pump so that the “Switch-

Genius” switch surface is 180° away

from the inlet. Make sure the incoming

water stream does not hit the “Switch-

Genius” surface.