3

PC1 and PC2 Series

www.waynepumps.com

Operation (Continued)

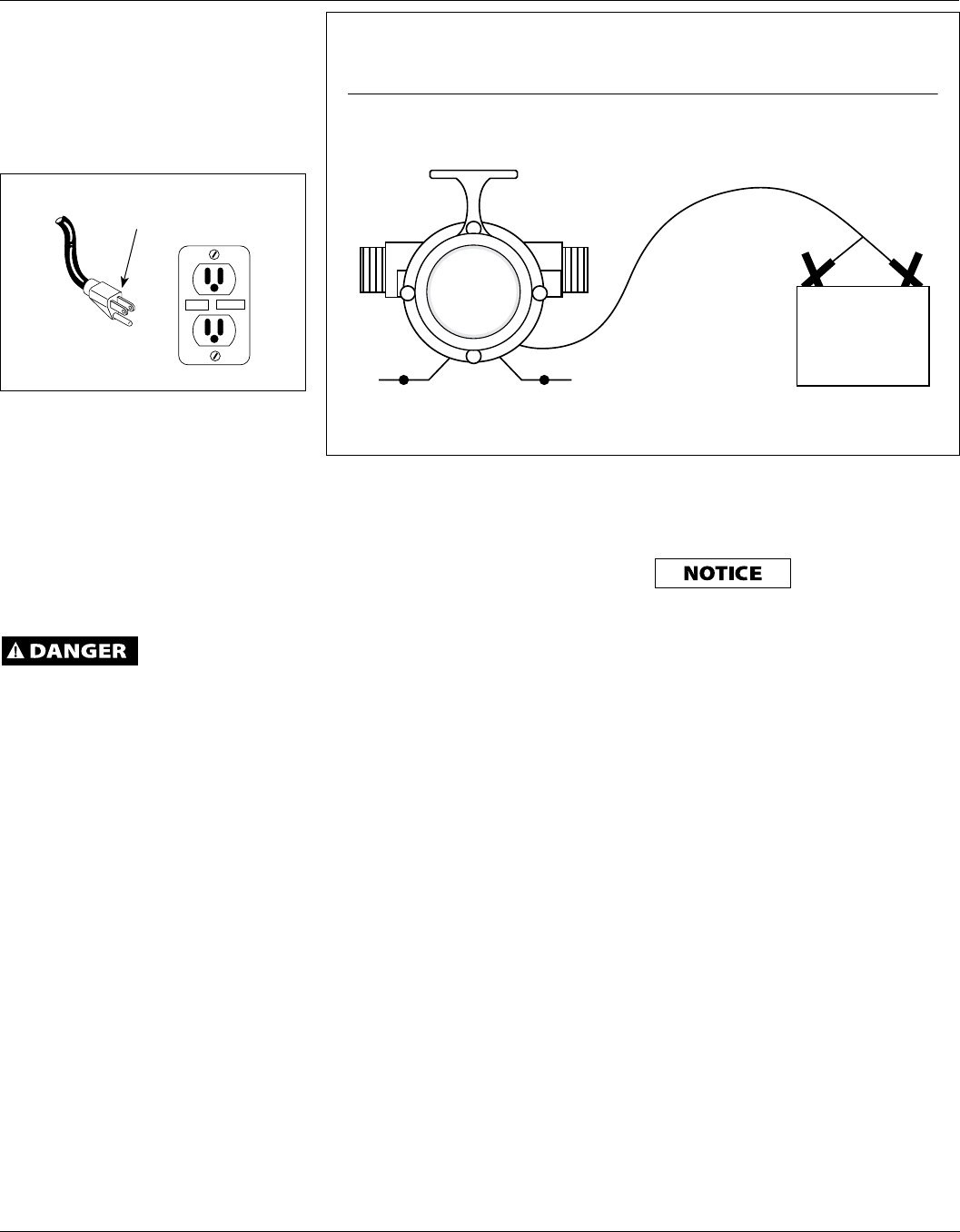

4. Connect pump to power source,

with pump in a dry location. Model

PC1: Motor must be connected to a

fully charged automotive tractor or

marine type battery to operate.

Connect the red clamp to the

positive (+) type battery terminal.

Connect the black clamp to the

negative (-) type battery terminal.

See 12V wiring diagram below

(Figure 2).

Model PC2: Plug into a

3-prong ground-type AC receptacle.

Maintenance

Always disconnect

power source

before attempting to install, service, or

maintain the pump.

IMPELLER REPLACEMENT

These parts are designed to handle

most clear, nonflammable liquids with

slight amounts of abrasives. When

impeller vanes become worn from use,

or damaged due to pumping abrasive

liquids or trash, pump performance will

be reduced or prevented altogether.

1. Remove the four cover plate screws

holding motor housing and pump

housing together. Cover plate is

now free and can be removed.

2. Inspect gasket and impeller for

wear and damage. If there is any

evidence of wear or damage, replace

the part(s).

3. Lubricate new impeller with white

grease or lightweight oil and

reinstall by aligning flat on impeller

hub with flat on motor shaft.

4. Reassemble gasket, cover plate, and

cover plate screws.

SHAFT SEAL REPLACEMENT

Motor shafts are sealed with factory

pre-lubricated lip-type seals which are

good for the life of the pump. If the

seal leaks, it is usually because the pump

has handled abrasive liquids. If the

motor shaft is scored (deep grooves),

the complete pump must be replaced.

1. Remove and inspect impeller parts as

specified in the impeller replacement

instructions. Replace worn parts.

2. Remove two pump body mounting

screws and slide pump body from

motor. Pry out seal retaining ring

and push worn shaft seal from inside

of pump body.

3. Lubricate new seal with lightweight

oil, push it into pump body with lip

facing away from motor, and push in

seal retaining ring.

4. Reassemble pump body onto motor

with mounting screws. Follow steps

3 and 4 in Impeller Replacement.

MOTOR BRUSH REPLACEMENT

Brushes for this

pump should be

inspected after 75 hours of operation

and replace if worn. They must be

replaced every 100 hours of operation.

Service one brush at a time.

1) Disconnect pump from power

supply.

2) Remove brush caps with screwdriver.

3) Remove old brush assembly.

4) Insert new brush assembly.

5) Replace brush caps.

TEST

RESET

Grounding Plug

Figure 1

12 VOLT WIRING DIAGRAM

RED CLAMP

TO POSITIVE

TERMINAL

BLACK CLAMP

TO NEGATIVE

TERMINAL

POS

+

12 VOLT DC

BATTERY

-

NEG

12 VOLT DC PUMP

INLETOUTLET

Figure 2