SECTION TSM 845 ISSUE F PAGE 7 OF 14

4. Insert a brass bar through a port between two rotor teeth

and loosen the capscrew holding the inner magnet to

the shaft (See Figure 11). Do not forget, this is a very

strong magnet. If pump disassembly is required, remove

the external retaining ring.

5. Do not remove the O-ring unless it is bad, especially

if PTFE (Derivative) encapsulated. If a new O-ring is

required, follow instructions in the “Assembly: Pump”

on page 7.

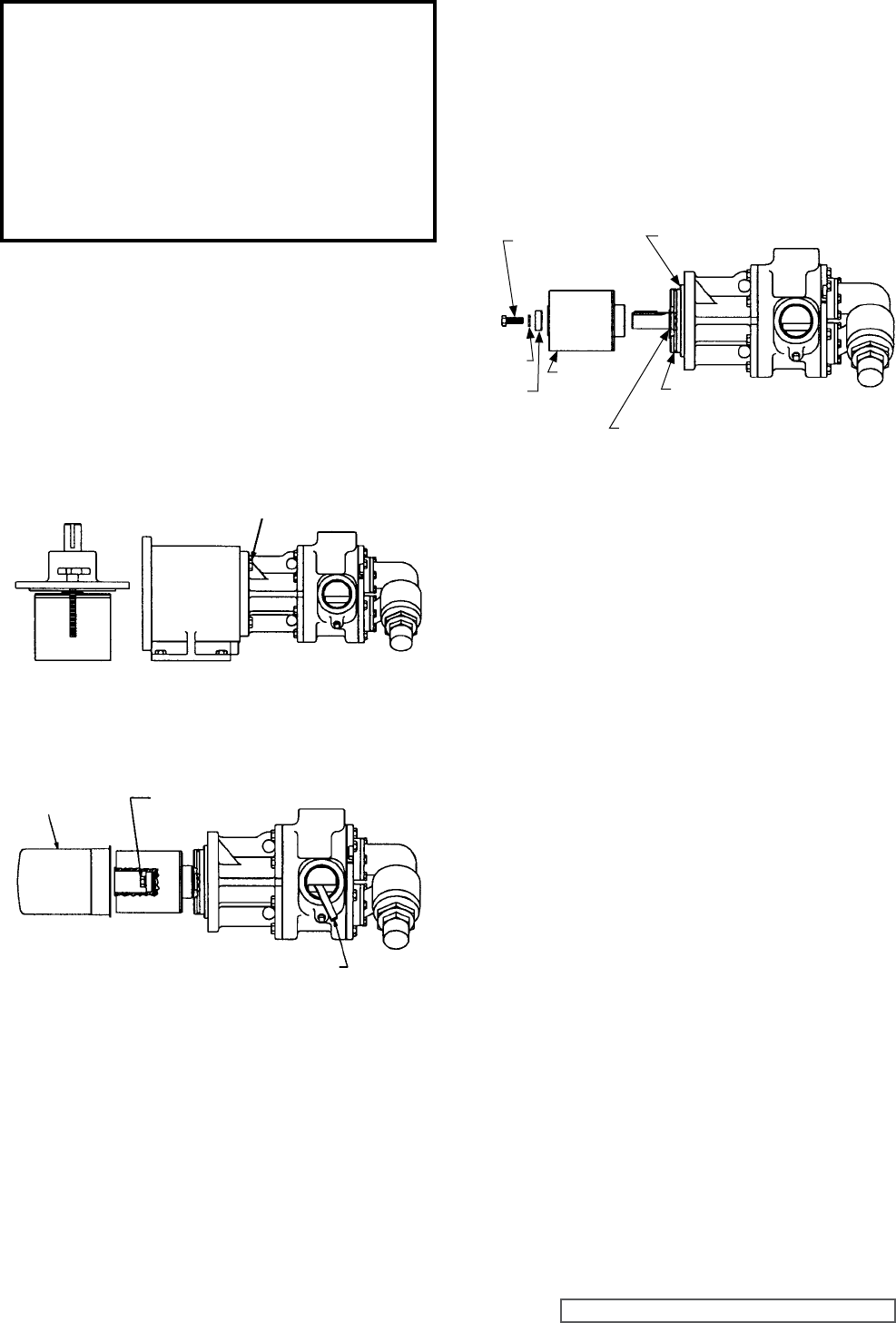

FIGURE 9

FIGURE 10

FIGURE 11

CAUTION !

Do not attempt to pull the magnet sets

apart by hand until the outer has been

backed off 4”. Support the outer magnet

assembly and pull completely away from

the inner magnet. Be careful when setting

down this unit to avoid tools and other

metal objects being attracted to the end of

the magnet.

3. Support pump with hoist and remove the (4) .5” capscrews.

See Figure 9. Pull the pump out of the bracket; there will

be some resistance to pull apart since the inner magnet

assembly will be attracted to the coupling bracket. If

further disassembly of the bearing carrier is required,

refer to page 7. Since there will be some liquid left in

the canister, be aware that liquid will run out when the

canister separates from the pump. Remove canister if it

has not already come off the pump.

0.5” CAPSCREWS (4 REQ’D)

0.44”

CAPSCREW

WITH HOLE

SECONDARY

O-RING

0.44” CAPSCREW RIGHT

HAND THREADS

CANISTER

BRASS BAR

WASHER

LOCK

WASHER

INNER

MAGNET

EXTERNAL

RETAINING

RING

PRIMARY

O-RING