11

107156

OWNER’S MANUAL

For more information, visit www.desatech.com

Installation Items Needed

• 5/16" hex socket wrench or nut-driver

• Phillips screwdriver

• sealant (resistant to propane/LP gas, not

provided)

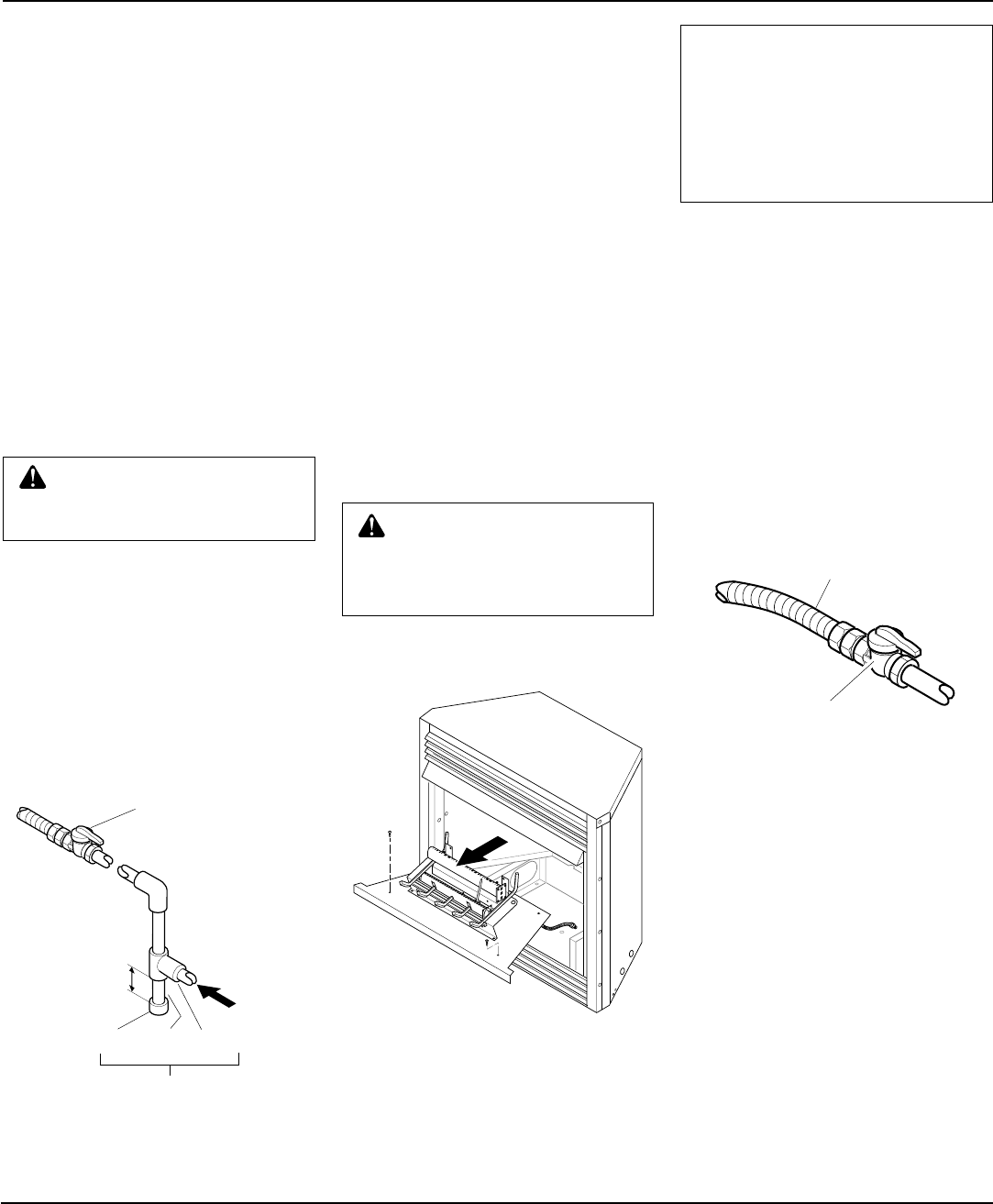

1. Remove fireplace screen. Remove two

screws that hold fireplace screen in

place for shipping. These screws are

located near top of screen. Discard

screws. Lift fireplace screen up and pull

out to remove.

2. Remove screws that attach log base

assembly to fireplace (see Figure 19).

Carefully lift up log base assembly and

remove from fireplace (see Figure 19).

Note:

If adding the G8000 series brick liner

accessory, install it now. Follow instruc-

tions in G8000 accessory kit.

CONNECTING FIREPLACE

TO GAS SUPPLY

CAUTION: Do not pick up log

base assembly by burners. This

could damage burners. Only

handle base by grates.

3. Route gas line (provided by installer)

from equipment shutoff through one of

the access holes.

Continued

Figure 19 - Removing Log Base Assembly

From Fireplace

Figure 20 - Attaching Flexible Gas Lines

Together

4. Attach flexible gas line to gas supply

(see Figure 20). Check connection of

flexible gas line attached to gas regu-

lator of fireplace (see Figure 20).

5. Check all gas connections for leaks. See

Checking Gas Connections, page 12.

6. Replace log base assembly back into

fireplace. Feed flexible gas line into fire-

place base area while replacing log base

assembly. Make sure the entire flexible

gas line is in fireplace base area. Reat-

tach log base assembly to fireplace with

screws removed in step 2.

To Fireplace

Gas Regulator

Flexible Gas Line

from Equipment

Shutoff Valve

Equipment

Shutoff Valve

Provided by

Installer

➞

➞

To External

Regulator

NOTICE: Most building codes do

not permit concealed gas con-

nections. A flexible gas line is

provided to allow accessibility

from the fireplace (see Figure 20).

The flexible gas supply line con-

nection to the equipment shutoff

valve should be accessible.

INSTALLATION

Continued

Figure 18 - Gas Connection

* Purchase the optional CSA design-certi-

fied equipment shutoff valve from your

dealer. See Accessories, pages 22 and 23.

Installation must include an equipment

shutoff valve, union, and plugged 1/8" NPT

tap. Locate NPT tap within reach for test

gauge hook up. NPT tap must be upstream

from fireplace (see Figure 17, page 10).

IMPORTANT:

Install equipment shutoff

valve in an accessible location. The equip-

ment shutoff valve is for turning on or

shutting off the gas to the appliance.

Check your building codes for any special

requirements for locating equipment shutoff

valve to fireplaces.

Apply pipe joint sealant lightly to male NPT

threads. This will prevent excess sealant

from going into pipe. Excess sealant in pipe

could result in clogged fireplace valves.

CAUTION: Use pipe joint seal-

ant that is resistant to liquid pe-

troleum (LP) gas.

We recommend that you install a sediment

trap in supply line as shown in Figure 18.

Locate sediment trap where it is within

reach for cleaning. Install in piping system

between fuel supply and fireplace. Locate

sediment trap where trapped matter is not

likely to freeze. A sediment trap traps mois-

ture and contaminants. This keeps them

from going into fireplace gas controls. If

sediment trap is not installed or is installed

wrong, fireplace may not run properly.

CSA Design-

Certified Equipment

Shutoff Valve With

1/8" NPT Tap*

3" Minimum

Cap Pipe Tee

Nipple Joint

Sediment Trap