23

Appendix A

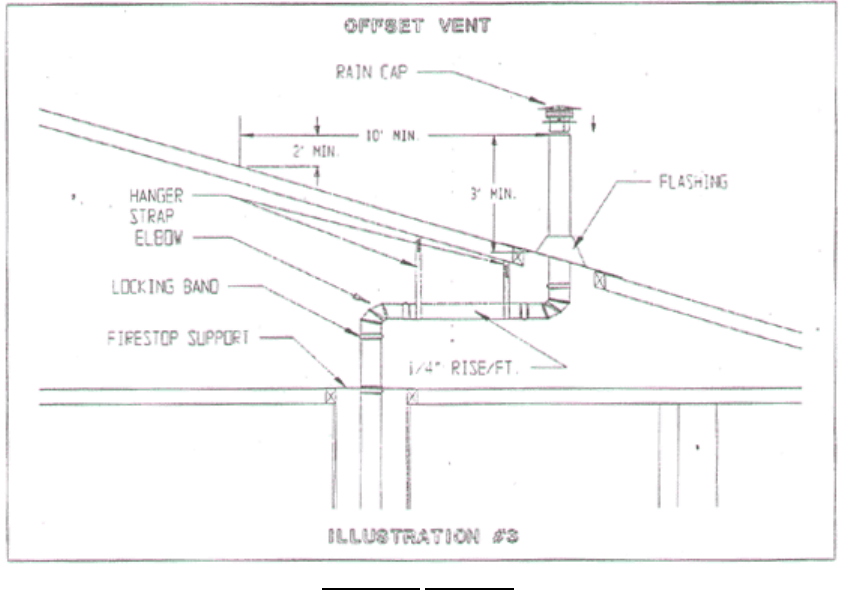

3. The system must be supported along its horizontal length at all elbow locations and joints (every forty-

eight inches or less) using straps around pipes maintaining clearance to combustibles as per table.

Any horizontally installed portion of a venting system shall have a slope (upwards for Category II, III, or

IV appliances or (upwards for Category Ill or IV appliances) not less than 1/4” (6.4 mm) every 12 inches

(305 mm) to prevent collection of condensate at any location in the assembly. The components of the

system must not be penetrated by fasteners either when joining pipes and fittings or using support

straps. The lengths of pipe may be cut on non-expanded end using aviation snips or a hacksaw (24 tpi).

The cut end must be filed or sanded smooth before joining. When installing the condensate tube, be sure

to form a trap by means of a 3” (76.2 mm) loop filled with water. This tube must be 3/8” ID high

temperature silicone for at least the first 6 inches (152 mm) and attached with a gear clamp or hose

clamp. The effluent must be disposed of according to local regulations.

NOTE: Z-FLEX recommends using a neutralizer kit when using a condensate trap. A condensate pump

may be required.

VERTICAL VENTING

NOTE: The vent termination must be at least 3 ft. (1 m) above the roof line and 2 ft. (.61 m) higher than

any part of a structure within 10 ft. (3.1 m). The total vertical distance of the vent system from appliance

flue collar to the rain cap termination and the maximum length of offsets shall not exceed that specified in

the appliance manufacturer’s installation instructions. No continuous vertical run shall be longer than

sixty feet (18.3 m). All horizontal sections must observe the rules for HORIZONTAL VENTING. The

clearance to combustibles inside a chase shall be no less than 4” (100 mm).

1. Prior to beginning the installation loosely assemble all parts required to make sure all parts are

present.

2. Locate position for venting system and proceed to cut holes for firestop support and firestop spacers.

All vertical installations require the use of a support. Frame the opening of the floor using lumber which is

dimensionally consistent with the structural members. Insert the support from beneath the framed

opening and secure with nails or screws as required.

Refer to JOINT PROCEDURE before assembling system.