6 U-Line Product Operation

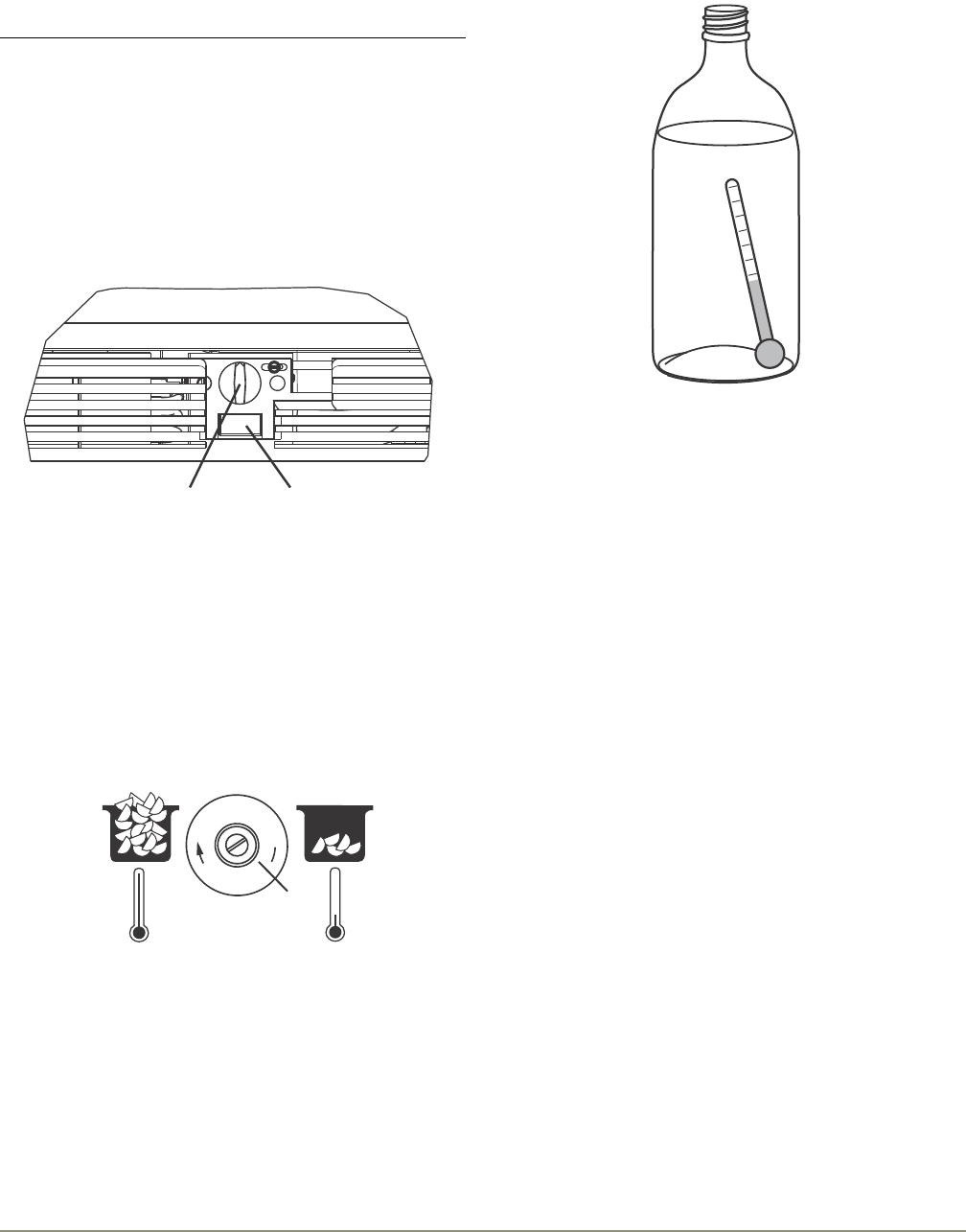

To check the actual product temperature in the unit.

1. Partially fill a plastic (nonbreakable) bottle with water.

2. Insert an accurate thermometer.

3. Tighten the bottle cap securely.

4. Place the bottle in the desired area for 24 hours.

5. Avoid opening the unit during the testing period.

6. After 24 hours, check the temperature of the water. If required,

adjust the temperature control in a small increment (See

ADJUSTING TEMPERATURE).

Causes which affect the internal temperatures of the

cabinet include:

• Temperature setting.

• Ambient temperature where installed.

• Installation in direct sunlight or near a heat source.

• The number of door openings and the time the door is open.

• The time the internal light is illuminated. (This mainly affects

product on the top rack or shelf.)

• The front grille or condenser are obstructed.

1

2

C

O

L

D

E

R

3

Adjusting AirTemperature

Combo Models

IMPORTANTIMPORTANT

• Adjust the set point temperature in single increments,

and wait 24 hours for the temperature to stabilize

before rechecking.

• Factory recommended set-point is MID setting on dial

control.

To adjust the set point temperature:

Adjust the temperature by turning the numbered dial (1) in

small increments.

Adjusting Ice Harvest

BI Models

1. Remove the front grille (see MAINTENANCE).

2. Turn the adjusting screw (3) using a flat tip screwdriver in a

small increment clockwise for a COLDER setting (slower ice

production) or counterclockwise for a WARMER setting (faster

ice production).

3. Replace the front grille (two screws).

Checking Product Temperature