5 DC-UC-WEB01

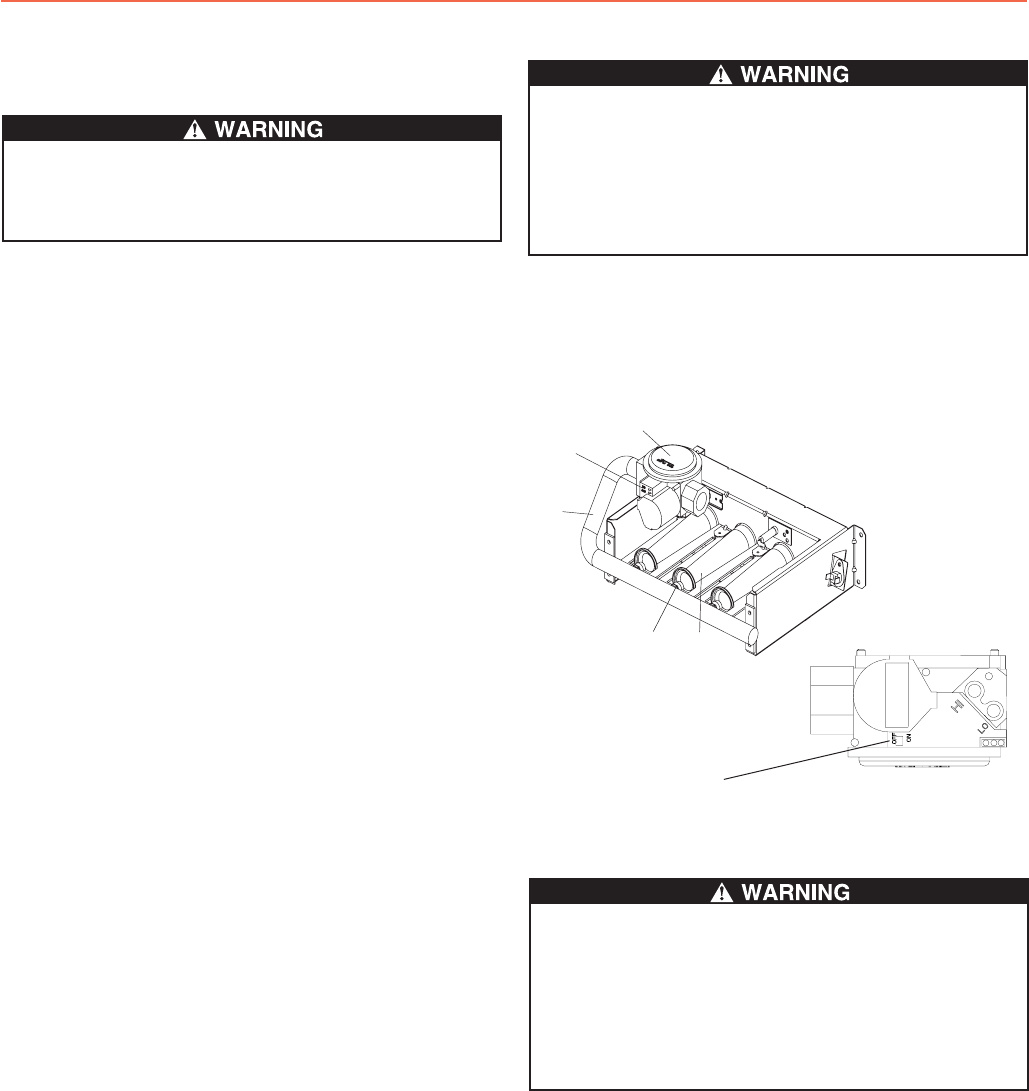

GAS VALVE

ORIFICE

BURNER

MANIFOLD

MANUAL

ON/OFF

SWITCH

Regular Service Maintenance

Cooling and Heating Season

Basic Maintenance – For All Packaged Systems

To keep your unit operating safely and efficiently, a qualified

service technician should check the entire system seasonally,

and any other time that you feel a check is needed. Your service

technician may examine these areas of the unit:

1. Filters(forpossiblecleaning)

2. Motors(condenserandevaporatormotorsare

permanentlylubricated)

3. Gaskets(forpossiblereplacement)

4. Refrigerantcoils(forpossiblecleaning)

5. Safetycontrols(formechanicalcleaning)

6. Electricalcomponentsandwiring(forpossible

replacementandconnectiontightness)

7. Condensatedrain(forpossiblecleaning)

8. Inspecttheunitductconnectionstoseethattheyare

physicallysoundandsealedtotheunitcasing.

9. Inspecttheunitmountingsupporttoseethatitissound.

10.Inspecttheunittoseethatthereisnoobviousunit

deterioration.

Heating Season Additional Maintenance – For

Gas/Electric and Dual Fuel Packaged Systems

At the beginning of each heating season arrange for a qualified

service technician to complete the unit inspections and service

routines described in this section.

These steps should be performed ONLY by a qualified service

technician.

1. Inspectthecontrolpanelwiringandheatingcontrolstomake

sureconnectionsaretightandwiringinsulationisintact.

2. Checktheoperationofthegasignitionsystem.

a.Turntheunitonandoffatthethermostattobesure

theignitioncontrolandsparkelectrodeareoperating.

b.Turnoffthegassupplywiththeunitoperatingto

verifythatthegasvalveclosesandthatare-ignition

cycleisinitiatedbytheignitioncontrol.

3. Checktheburnermanifoldpressure.Apressuretapis

providedinthegasvalveforthispurpose.

4. Visuallyinspectalloftheunit'sueproductpassageways

forexcessivedepositbuilduporcorrosion.Ifbuildupor

corrosionisapparent,performthenecessaryrepairs.

5. Visuallycheckthemainburnerames.Theyshouldbebright

blueamesextendinguptotheheatexchangersections.

ELECTRIC SHOCK HAZARD

To prevent injury or death due to electrical shock or contact

with moving parts. Lock unit disconnect switch in open

position before servicing unit.

HAZARDOUS GASSES

Exposure to fuel substances, or by-products of incomplete fuel

combustion, is believed by the state of California to cause cancer,

birth defects, or other reproductive harm.

This warning complies with State of California law, Proposition 65.

This product must be gas piped by a Licensed Plumber or Gas

Fitter in the Commonwealth of Massachusetts.

ELECTRIC SHOCK HAZARD

Should overheating occur, or the gas supply fail to shut off, shut

off the manual gas valve to the furnace before shutting off the

electrical supply.

In the event that electrical, fuel or mechanical failures occur, the

owner should immediately turn off the gas supply at the manual

gas valve located in the burner compartment and electrical

power to the furnace and contact service technician.

GASVALVE

ManualOn/OffSwitch

Figure 2. Gas Valve with On/Off "Toggle" Switch

IMPORTANT: Some of these products have been designed

and manufactured to meet ENERGY STAR criteria for energy

efficiency. However, proper refrigerant charge and proper

air flow are critical to achieve rated capacity and efficiency.

Installation of this product should follow the manufacturer’s

refrigerant charging and air flow instructions. Failure to confirm

proper charge and airflow may reduce energy efficiency and

shorten equipment life.

For regular dealer maintenance please refer to

www.acca.org/industry/quality