12 WSHP-SVX02A-EN

Cleaning and Flushing

the Water Loop

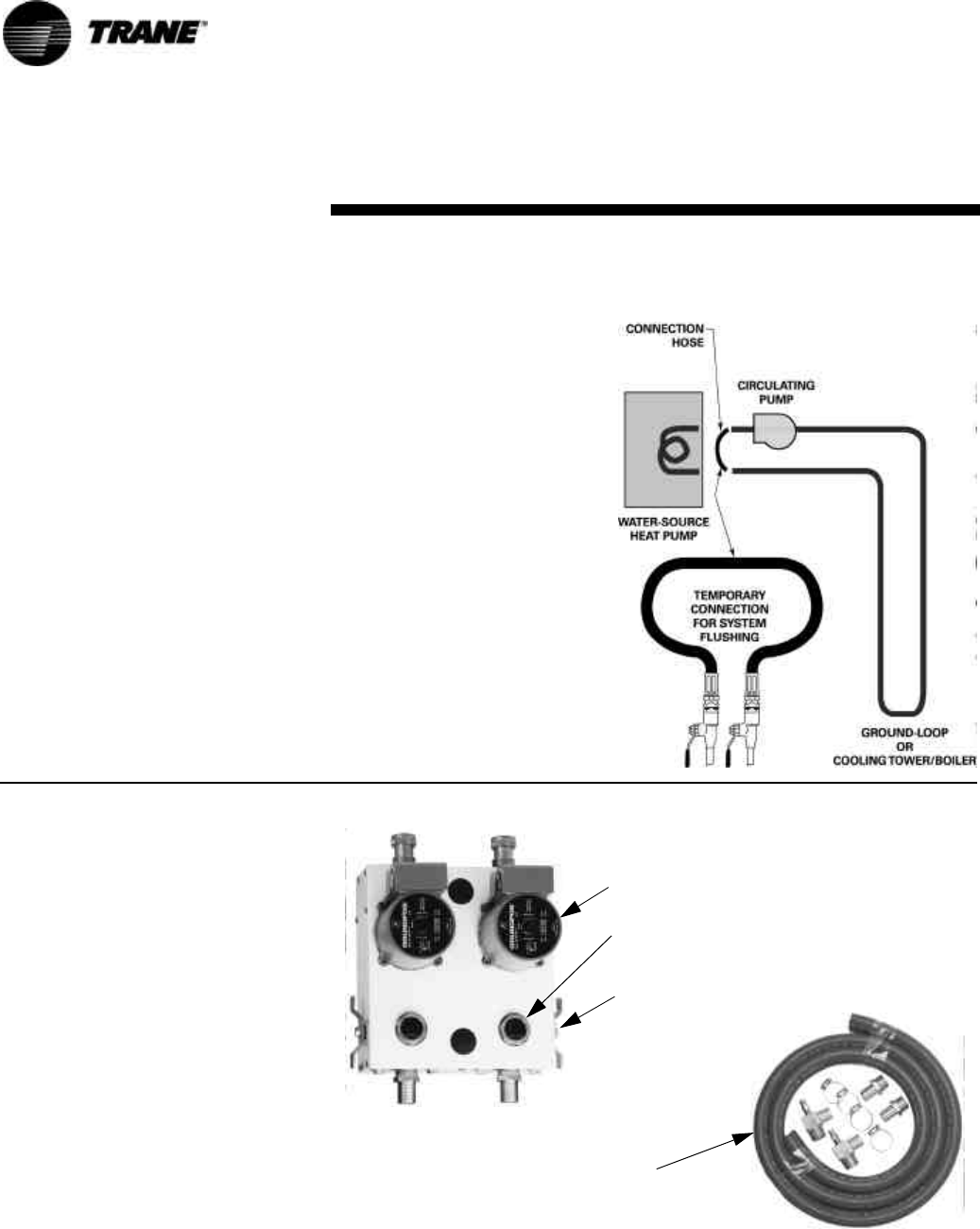

After the piping system is complete,

the flexible hose connectors should be

doubled back to complete the water

circuit external to the unit (avoiding

trash settle-out in the condenser). Fig-

ure 4. An extra pipe may be necessary

to connect the hose kits. See Page 14

for antifreeze/water mixture by vol-

ume.

(1) Water circulation system should be

filled with clean water using the water

make up connections. Note: Air vents

should be opened during filling.

(2) With the air vents closed, start the

circulating pump and then crack the air

vents to bleed off the trapped air, as-

suring circulation through all compo-

nents of the system.

Note: Make up water must be available

to the system to replace the volume

formerly occupied by the air that is

bled off.

(3) With the air vented and the water

circulating, the entire system

should be checked for leaks with re-

pairs made as required.

(4) Operate the supplementary

heat system making checks per

manufacturer’s instructions. Dur-

ing this operation, visual checks

should be made for leaks that may

have occurred due to increased

heat. Repair as required.

(5) Open the system at the lowest

point for the initial blow down

(making sure the make up water is

equal to the water being dumped).

Continue blow down until the water

leaving the drain runs clear, but not

less than 2 hours.

(6) Shut down pumps and supplemen-

tary heat system. Reconnect the hoses

placing the water-to-refrigerant heat

exchanger in the water circulating sys-

tem.

Note: Vents should be open when the

pumps and supplementary heat sys-

tem are shut down.

Installation

SHUT-OFF 3-WAY

PURGING CAP (2)

BRONZE OR CAST IRON PUMP

FROM UNIT’S

W.O.

TO UNIT’S

W.I.

Figure 5 Pump module

Figure 6: Hose kit

1" MPT x BARB FITTINGS,

1" MPT x BARB ELBOWS with

PRESSURE TEMPERATURE PORTS,

AND 10’ OF RUBBER HOSE with

4 HOSE CLAMPS.

VALVE (2)

Connecting a Loop Pump Kit

Closed Loop System

All piping external to the unit is the re-

sponsibility of the installer. The water

pipe installation must be done in ac-

cordance with local codes. If no local

code applies, national codes should be

followed. It is the contractor’s respon-

sibility to know and adhere to all appli-

cable codes.

Water inlet and outlet to the unit’s wa-

ter-to-refrigerant heat exchanger are

clearly marked on the submittal draw-

ings found on pages 7 through 9. The

supply and return piping must be in-

stalled correctly to the unit to ensure

the safety devices will work properly.

Units that are not piped accordingly

will not obtain the manufacturers war-

ranty.

A pump module (Figure 5) and hose kit

(Figure 6) are typically used to connect

the unit to closed loop piping in do-

mestic applications.

Figure 4: Flushing water loop