|nstaI|er's Guide

10. Replace liquid service pressure tap port cap and valve

stem cap. These caps MUST BE REPLACED to

prevent leaks. Replace valve stem and pressure tap cap

finger tight, then tighten an additional 1/6 turn.

11. The gas valve can now be opened. Open the gas valve by

removing the shut-off valve cap and turning the valve

stem 1/4 turn counterclockwise, using 1/4" Open End or

Adjustable wrench. See Figure 4.

12. The gas valve is now open for refrigerant flow. Replace

valve stem cap to prevent leaks. Again, these caps

MUST BE REPLACED to prevent leaks. Replace valve

stem and pressure tap cap finger tight, then tighten an

additional 1/6 turn. See Figure 4.

If refrigerant lines are longer than 15 f_et and/or a difi_rent

size than recommended, it will be necessary to adjust system

refrigerant charge upon completion of installation. See unit

Service Facts.

E. ELECTRICAL CONNECTIONS

When installing or servicing this equipment, ALWAYS

exercise basic safety precautions to avoid the possibility

of electric shock.

1. Power -wiring and grounding of equipment must comply

with local codes.

2. Power supply must agree with equipment nameplate.

3. Install a separate disconnect switch at the outdoor unit.

4. Ground the outdoor unit per local code requirements.

5. Provide flexible electrical conduit whenever vibration

transmission may create a noise problem within the

structure.

6. The use of color coded low voltage wire is recommended

to simplify connections between the outdoor unit, the

thermostat and the indoor unit.

Table 1 -- NEC Class II Control Wiring

serves to sense outdoor coil temperature for termination of

the defrost cycle.

FAULT IDENTIFICATION

A fault condition is indicated by the flashing light on the

defrost control inside the heat pump control box.

In normal operation, the defrost control light will flash once

each second. If the light is flashing more than once per

second or not at all, refer to the service manual for that unit.

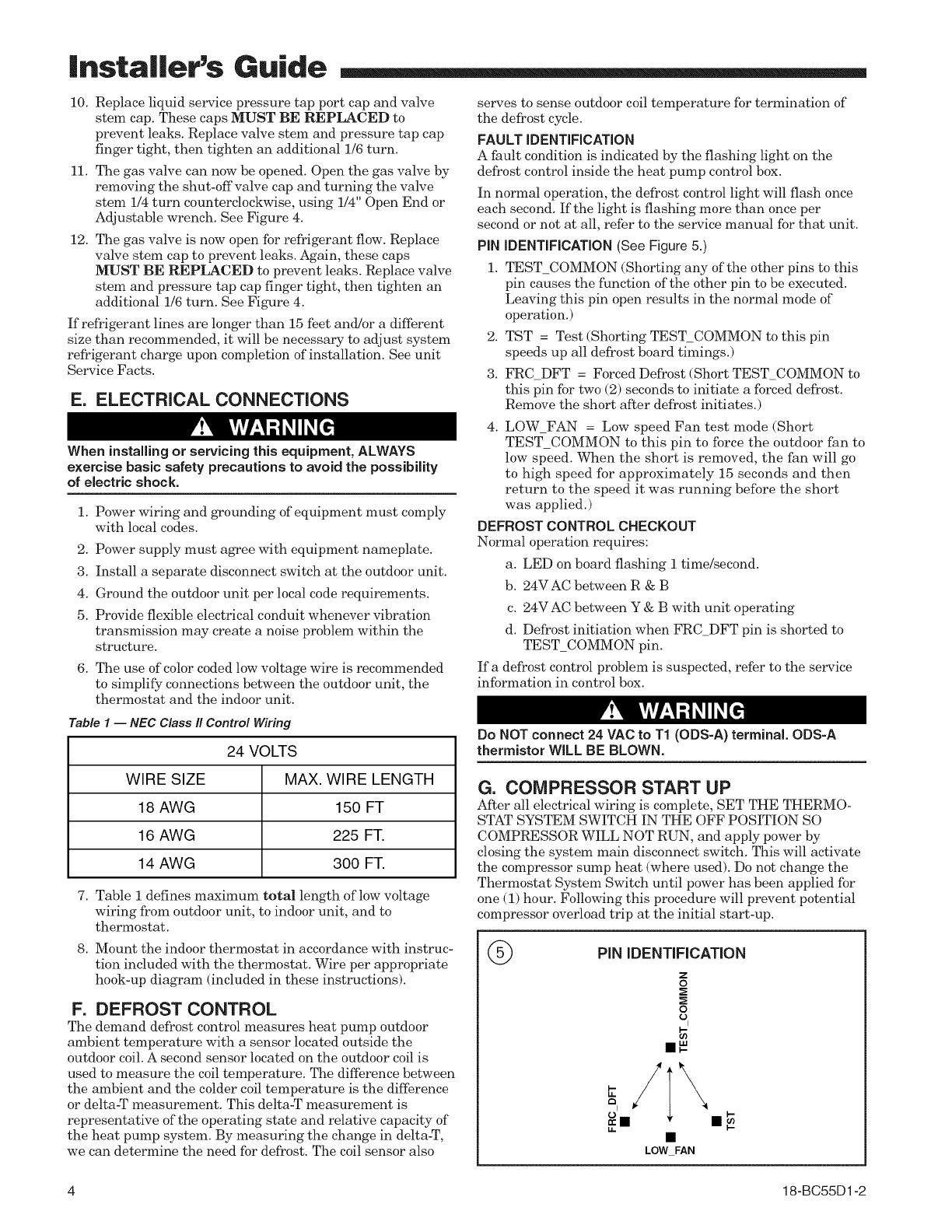

PIN IDENTIFICATION (See Figure 5.)

1. TEST COMMON (Shorting any of the other pins to this

pin causes the function of the other pin to be executed.

Leaving this pin open results in the normal mode of

operation.)

2. TST = Test (Shorting TEST_COMMON to this pin

speeds up all defrost board timings.)

3. FRC_DFT = Forced Defrost (Short TEST_COMMON to

this pin for two (2) seconds to initiate a forced defrost.

Remove the short after defrost initiates.)

4.

LOW_FAN = Low speed Fan test mode (Short

TEST_COMMON to this pin to force the outdoor fan to

low speed. When the short is removed, the fan will go

to high speed for approximately 15 seconds and then

return to the speed it was running before the short

was applied.)

DEFROST CONTROL CHECKOUT

Normal operation requires:

a. LED on board flashing 1 time/second.

b. 24V AC between R & B

c. 24V AC between Y & B with unit operating

d. Defrost initiation when FRC DFT pin is shorted to

TEST_COMMON pin.

If a defrost control problem is suspected, refer to the service

information in control box.

24 VOLTS

WIRE SIZE MAX. WIRE LENGTH

18 AWG 150 FT

16 AWG 225 FT.

14 AWG 300 FT.

7. Table i defines maximum total length of low voltage

wiring from outdoor unit, to indoor unit, and to

thermostat.

8. Mount the indoor thermostat in accordance with instruc-

tion included with the thermostat. Wire per appropriate

hook-up diagram (included in these instructions).

F. DEFROST CONTROL

The demand defrost control measures heat pump outdoor

ambient temperature -with a sensor located outside the

outdoor coil. A second sensor located on the outdoor coil is

used to measure the coil temperature. The difference between

the ambient and the colder coil temperature is the difference

or delta-T measurement. This delta-T measurement is

representative of the operating state and relative capacity of

the heat pump system. By measuring the change in delta-T,

we can determine the need for defrost. The coil sensor also

Do NOT connect 24 VAC to T1 (ODS-A) terminal. ODS-A

thermistor WiLL BE BLOWN.

G. COMPRESSOR START UP

After all electrical wiring is complete, SET THE THERMO-

STAT SYSTEM SWITCH IN THE OFF POSITION SO

COMPRESSOR WILL NOT RUN, and apply power by

closing the system main disconnect switch. This will activate

the compressor sump heat (where used). Do not change the

Thermostat System Switch until power has been applied for

one (1) hour. Following this procedure -will prevent potential

compressor overload trip at the initial start-up.

@

PiN iDENTiFiCATiON

z

0

0

o

I

k-

)m

LOW FAN

4 18-BC55D 1-2