–32–

SMMS-i

Installation Manual

EN

SMMS-i

Installation Manual

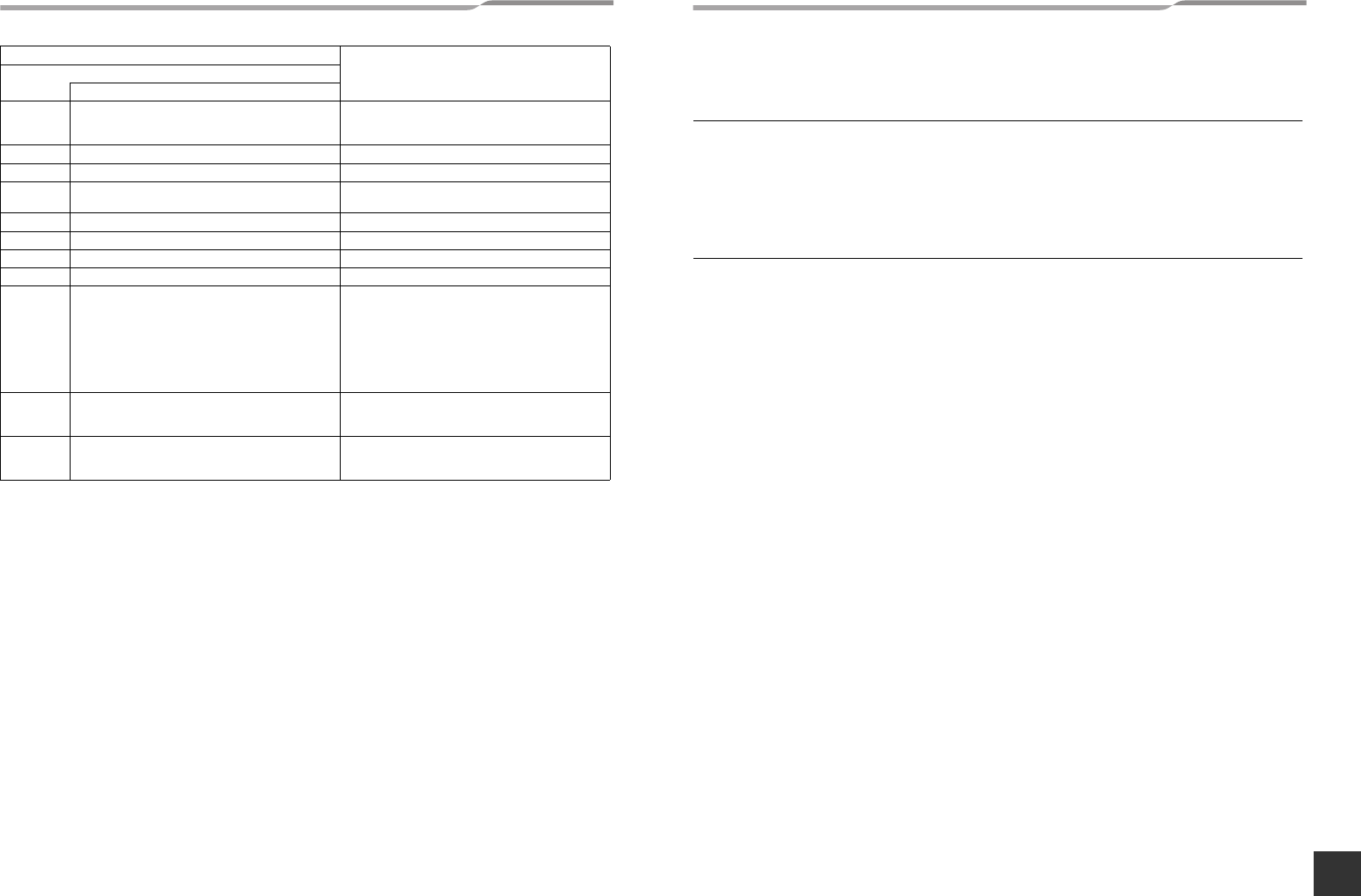

*1PDU number information

01:Compressor 1

02:Compressor 2

03:Compressors 1 and 2

04:Compressor 3

05:Compressors 1 and 3

06:Compressors 2 and 3

07:Compressors 1, 2 and 3

08:Fan

09:Compressor 1 and fan

0A:Compressor 2 and fan

0B:Compressors 1, 2 and fan

0C:Compressor 3 and fan

0D:Compressors 1, 3 and fan

0E:Compressors 2, 3 and fan

0F:Compressors 1, 2, 3, and fan

P07

01: Compressor 1

02: Compressor 2

03: Compressor 3

Heat sink overheat error

P10 Detected indoor unit address Indoor overflow error

P13 — Outdoor unit flow back error detected

P15

01: TS condition

02: TD condition

Gas leak detection

P17 — Discharge temperature TD2 error

P18 — Discharge temperature TD3 error

P19 Detected outdoor unit number 4-way valve inverse error

P20 — High-pressure protective operation

P22

0 *: IGBT circuit

1 *: Position detection circuit error

3 *: Motor lock error

4 *: Motor current detected

C *: TH sensor error

D *: TH sensor error

E *: Inverter DC voltage error

(outdoor unit’s fan)

Outdoor fan IPDU error

(NOTE)

Ignore 0-F appearing in the position of “*”.

P26

01: Compressor 1

02: Compressor 2

03: Compressor 3

G-TR short protection error

P29

01: Compressor 1

02: Compressor 2

03: Compressor 3

Compressor position detecting circuit error

Check code

Check code nameIndication on 7-segment display on the outdoor unit

Auxiliary code

12 MACHINE CARD AND LOGBOOK

Machine card

After test run, fill the items on the machine card and paste the card on an accessible place on the product securely before

delivery to the customer.

Describe the following items on the machine card:

name, address and telephone number of the installer, his service department, the service department of the party concerned

or at any addresses and telephone numbers of fire department, police, hospitals and burn centres;

Logbook

Update the log periodically after maintenance as defined in EN378-4.

Describe the following items on the logbook:

1. details of the maintenance and repair works;

2. quantities, kind of (new, reused, recycled) refrigerant which have been charged on each occasion, the quantities

of refrigerant which have been transferred from the system on each occasion (see also EN378-4);

3. if there is an analysis of a reused refrigerant, the results shall be kept in the logbook;

4. source of the reused refrigerant;

5. changes and replacements of components of the system;

6. result of all periodic routine tests;

7. significant periods of non-use.

63-EN 64-EN

+00EH99871699_01EN.book Page 32 Thursday, August 26, 2010 4:41 PM