154

Toshiba

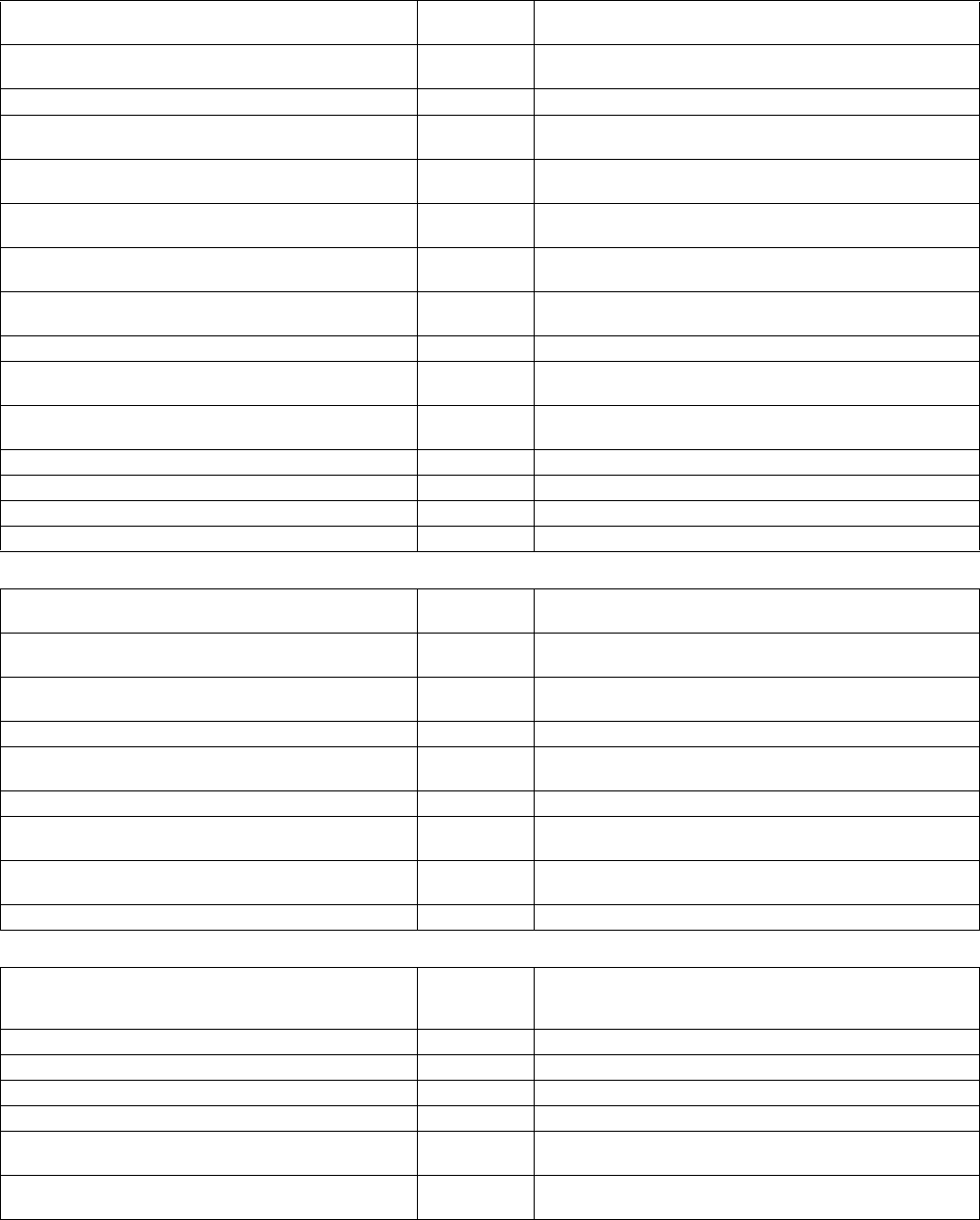

12 Periodic Inspection Items

For a long-term safe operation of this equipment, perform periodic inspection and parts replacement.

<Inspection items>

Hydro unit

(HWS-802**-E, 1402**-E)

Frequency Periodic inspection details

1. Insulation measurement (Power source circuit/ Heater

circuit)

Annually Insulation measurement with a mega tester

2.Power source measurement (No-load voltage) Annually Electronic voltage measurement: 230V ±23V

3.Operation check Annually Hot water supply/ Heating/ Cooling operation check with

remote controller

4.Refrigerant leakage/ Water leakage inspection Annually Visual inspection and check with a leak tester: No leakage

must be found

5.Water heat exchanger inspection (Internal dirt and

clogging)

Annually Checking for water dirtiness in a closed cycle, Cleaning

6.Inlet/ Outlet water temperature measurement Annually Temperature measurement: Temperature measurement

during an operation

7.Circulation pump inspection Annually No leakage or abnormal noise must be found (Replacement

every 10 years: Charged)

8.Air vent valve inspection Annually Water leakage, Air vent

9.Expansion vessel Annually Visual check for charge pressure abnormality, water

leakage, or corrosion

10. Heater assembly Annually Check for appearance damage, deformation, or loose

terminal

11. Flow switch Annually Operation check while running

12. Manometer Annually Water leakage, water pressure check

13. Safety valve Annually Water leakage, Appearance check, Drainage check

14. Water heat exchanger control board, Terminal block Annually Check for loose connector and connecting terminal

Outdoor unit

(HWS-802H-E, 1102H-E, 1402H-E)

Frequency Periodic inspection details

1.Insulation measurement (Power source circuit/

Compressor)

Annually Insulation measurement with a mega tester

2.Power source measurement (No-load voltage/ Rated

operation)

Annually Electronic voltage measurement: 230V ±23V

3.Operation frequency (Outdoor unit operation check) Annually Frequency check by rated operation (See 10-13)

4.Refrigerant leakage inspection Annually Visual inspection and check connection with a leak tester:

No leakage must be found

5.Air heat exchanger inspection (Dirt and clogging) Annually Visual inspection, Clear clogging

6.Fan inspection (Scratch, damage) Annually Check for scratches or damages to the fan or abnormal

motor sound

7.Cycle parts

(Compressor, 4-way valve, Pulse motor valve)

Annually

Annually

Operation check by trial run

8.Inverter control board, Terminal block Annually Check for loose connector and connecting terminal

Hot water cylinder

(HWS-150CSHM3-E(-UK),

210CSHM3-E(-UK), 300CSHM3-E(-UK))

Frequency Periodic inspection details

1.Insulation measurement (Power source circuit) Annually Insulation measurement with a mega tester

2.Power source measurement (No-load voltage) Annually Electronic voltage measurement: 230V ±23V

3.Water leakage inspection Annually Visual inspection for leakage: No leakage must be found

4.Terminal block Annually Check for loose connector and connecting terminal

5.Heater assembly Annually Check for appearance damage, deformation, or loose

terminal

6.Temperature, Pressure relief valve (Specification for

UK only)

Annually Drainage check

+00A09-002_01EN_SVM_ALL_Air_to_Water.book Page 154 Monday, October 5, 2009 2:09 PM