TOSHIBA INTERNATIONAL CORPORATION

INDEX MDS-O-0001

Industrial Division / Houston Motor Plant

SHEET NO. 2 of 3

ISSUED 01/24/96

Motor O

p

eration Procedure

SUPERSEDES NEW

3. STANDARD SERVICE (-cont.)

5. Remove relief plug or plate and using a low pressure hand held grease gun, pump the required

amount of grease.

6. For Frames 143T to 365T allow motor to run for 20 to 30 minutes and for Frames 405T and

larger allow motor to run for 30 to 60 minutes before replacing hardware.

7. Grease may not relieve from drain. Use volumes recommended to avoid overgreasing.

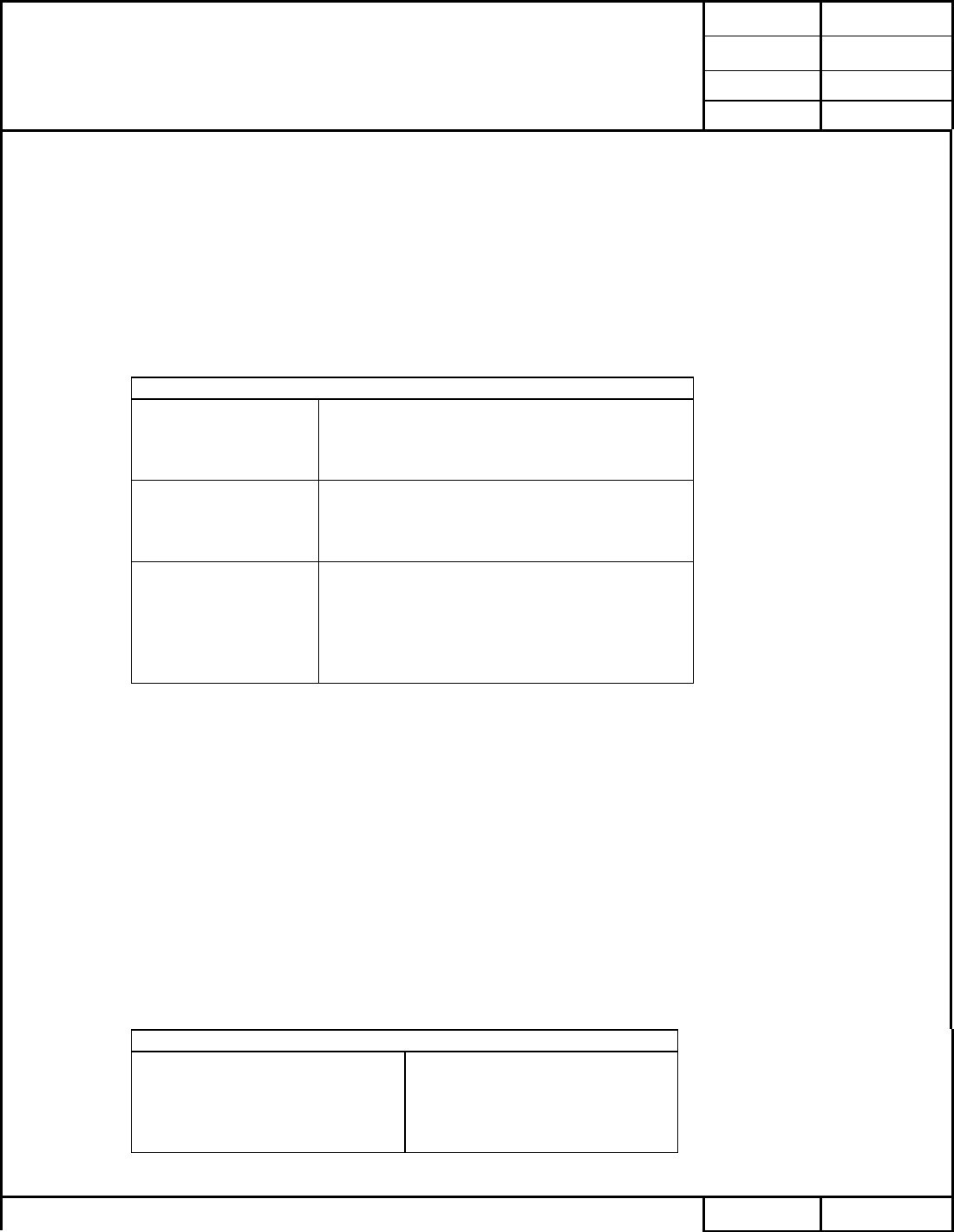

Fig. 2 SERVICE CONDITIONS

Standard Duty Eight hours per day;

Light to normal loading;

Clean condition, free from dust.

Severe Duty 24 hours per day;

Light to normal shock loading, vibration;

Exposure to dirt or dusty conditions.

Very Severe Duty 24 hours per day;

High ambient;

Normal to high shock loading, vibration;

Dusty conditions;

Confined mounting conditions

4. RECOMMENDED GREASES:

Confirm if the motor nameplate has specified the grease used.

Standard, Severe Duty and 841 motors greased at the factory will use:

Grease Name: Chevron SRI

Manufactured By: Chevron U.S.A., Inc.

Operating Ambient Temp.: -30°C to 50°C

5. RECOMMENDED GREASES for STANDARD APPLICATIONS

Use the following greases listed for the given temperature range, unless otherwise shown by the motors

grease nameplate:

Operating Ambient Temp. -30°C to 50°C

Chevron SRI

Exxon Unirex #2

Exxon Polyrex

Shell Dolium R

Polystar RB 2

Chevron U.S.A., Inc.

Exxon Corp.

Exxon Corp.

Shell Oil Co.

Texaco

TOSHIBA INTERNATIONAL CORPORATION

INDEX MDS-O-0001