Form RZ-NA I-UDA, P/N 195673 Rev 5, Page 18

18. Flame

Rollout

Switch -

Sizes 30-125

only

16. Combustion

Air Proving

Switch

(cont’d)

Sizes 30-125 are equipped with a temperature activated manually reset flame rollout

switch. The flame rollout switch is located at the top of the burner assembly. It is

factory set and is non-adjustable. If the setpoint is reached, the flame rollout acts to

interrupt the electric supply to the gas valve. If the flame rollout switch activates,

identify and correct the cause before resetting the switch. Refer to the Mainte-

nance Section for information on probable causes and instructions on resetting the

flame rollout switch. (For location, see FIGURE 18, page 31.)

DANGER: If the manual reset flame rollout switch activates,

identify and correct the cause before resetting the switch. Never

bypass the flame rollout switch; hazardous conditions could result.

See Hazard Intensity Levels, page 2.

17. Limit Control

All units are equipped with a temperature activated auto reset limit control. The

control is factory set and is non-adjustable. If the setpoint is reached, the limit

control will interrupt the electric supply to the gas valve. This safety device pro-

vides protection in the case of motor failure or lack of airflow due to a restriction at

the inlet or outlet. (For location, see FIGURE 18, page 31.)

CAUTION: The auto reset limit control will continue to shut down

the heater until the cause is corrected. Never bypass the limit

control; hazardous conditions could result. See Hazard Intensity

Levels, page 2.

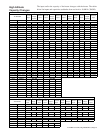

The two Tables on the left below list the approximate water column negative pres-

sure readings and switch setpoints for sea level operating conditions for Model

UDAP and Model UDAP-CV heaters. The Table on the right lists the approximate

water column differential pressure readings and switch setpoints for sea level op-

erating conditions for Model UDAS heaters.

Pressure Switch Settings

DANGER: Safe operation of this unit requires proper venting

flow. NEVER bypass combustion air proving switch or attempt

to operate the unit without the venter running and the proper

flow in the vent system. Hazardous conditions could result. See

Hazard Levels, page 2.

Startup Equilibrium Setpoint Setpoint Startup Equilibrium Setpoint Setpoint

Cold Hot OFF ON Cold Hot OFF ON

30 1.00 0.78 0.40 0.58 Green 197030 30 1.00 0.78 0.65 0.83 Yellow 197028

45 0.95 0.75 0.40 0.58 Green 197030 45 1.05 0.80 0.65 0.83 Yellow 197028

60 1.00 0.78 0.50 0.68 Orange 196388 60 1.10 0.85 0.65 0.83 Yellow 197028

75 1.00 0.85 0.50 0.68 Orange 196388 75 1.10 0.85 0.65 0.83 Yellow 197028

100 0.85 0.72 0.50 0.68 Orange 196388 100 0.85 0.72 0.55 0.73 White 196362

125 0.75 0.60 0.40 0.58 Green 197030 125 0.75 0.60 0.45 0.63 Pink 197032

150, 175 0.75 0.65 0.40 0.58 Green 197030 150, 175 0.75 0.60 0.40 0.58 Green 197030

200, 225 2.20 1.50 1.10 1.30 Blue 201158 200, 225 2.20 1.50 1.10 1.30 Blue 201158

250, 300 2.30 1.60 1.10 1.30 Blue 201158 250, 300 2.30 1.60 1.10 1.30 Blue 201158

350, 400 2.60 1.80 1.40 1.60 Red 201159 350, 400 2.60 1.80 1.40 1.60 Red 201159

Startup Equilibrium Setpoint Setpoint

Cold Hot OFF ON

1.10 0.84 0.65 0.83 Yellow

1.10 0.81 0.50 0.68 Orange

0.92 0.75 0.60 0.78 Lt Blue

0.97 0.78 0.60 0.78 Lt Blue

0.88 0.71 0.55 0.73 White100

Switch

P/N

197028

196388

197029

197029

196362

30

45

60

75

Differential Pressure Measured in " w.c.

Model

UDAS

Label

Color

Switch

P/N

Negative Pressure Measured in " w.c.

Label

Color

Switch

P/N

Model

UDAP

Label

Color

Negative Pressure Measured in " w.c.

Model UDAP-CV

with Opt AV6