22

J. OIL FILTER:

It is strongly recommended that an oil filter assembly be installed in the oil supply line to the unit. This

filter should have the capacity to trap a 40-50 micron particle.

The filter cartridge should be replaced at least once a year. The filter body should be thoroughly cleaned

before installing a new cartridge.

K. ELECTRICAL WIRIING:

: This appliance must be grounded in accordance with local codes, or in the absence

of local codes, with the National Electrical Code

, ANSI/NFPA 70-1999, or the latest edition.

All wiring must conform to the provisions of local codes or, in the absence of local codes, with the

provisions of the National Electrical Code

, ANSI/NFPA 70-1999, or the latest edition, and this instruction

manual.

This appliance requires 120 VAC, 60 Hz, single-phase power. Refer to Table 10 for typical electrical

current draws of the individual appliance motors, recommended sizes for over-current and short circuit

devices, and minimum recommended field wiring sizes. Electrical service must be brought to the unit from

a circuit breaker, or fused disconnect switch, in accordance with local codes. The disconnecting switch

must be located reasonably close to and within sight of the unit. Care must be taken to ensure correct

polarity when wiring the furnace.

Two-wire service, one “hot” lead (L1) and a common (L2), plus a ground conductor, is required. Connect

power to the appliance control system at the junction box in the burner compartment. (A knockout fitting is

provided on the exterior of the burner compartment for this purpose.) A ground wire must be connected to

the grounding wire in the junction box.

Field wiring of power circuits to the appliance should consist of copper conductors rated for at least

15 amp service with an insulation temperature rating of at least 75°C temperature rise. Depending upon

code requirements, rigid or flexible conduit is recommended, and may be required. Connect the electric

power supply as shown in the wiring diagram located on the inside of the front door.

Typically, control wiring between the appliance and the indoor thermostat, and if used, electronic air

cleaner or humidifier, will be required. Field wiring of control circuits should consist of copper conductors

rated for at least 15 amp service with an insulation temperature rating conforming to Type T wire, 35°C

temperature rise. Depending upon code requirements, rigid or flexible conduit is recommended, and may

be required. Make connections between the thermostat, and electronic air cleaner or humidifier (if used),

and the fan control module, inside the vestibule. Consult the wiring diagram for the appropriate

connection points on the thermostat and the fan control module.

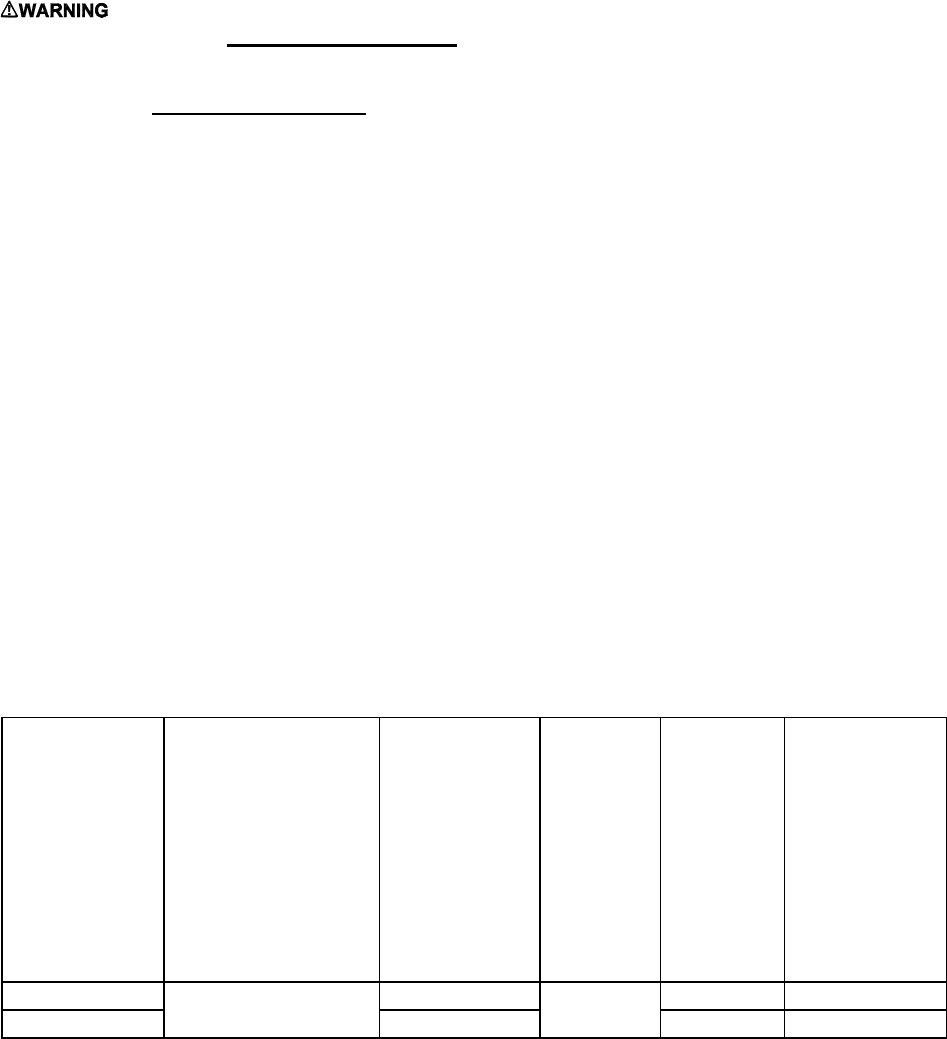

Model

Potential/Frequency/

No. of Phases

(V/Hz/Ph)

Supply/Return

A

ir Blower Full

Load Current

(Amps) @ 115

VAC

Oil Burner

Assembly

Full Load

Current

(Amps) @

115 VAC

Maximum

Time Delay

Type Fuse

or Inverse

Time

Circuit

Breaker

Size

(Amps)

Minimum

Recommended

75 deg. C.

Copper Power

Wiring Size

(AWG)

OL6*A072D48 8.0 PSC 15 12

OL6**072DV5 10.1 ECM 15 12

2.6120/60/1

Table 10: Typical Electrical Requirements