All installations and services must be performed by qualified service personnel.

3

NOTE: ROTATION OF FLUE PIPE IS ONLY ALLOWED FOR LEFT HAND SIDE VENTING

APPLICATIONS.

TABLE 1: Suggested sizes and positions of flue pipe opening on left hand side of casing.

TRIM COLLAR/

UNIT DIA. HOLE “X” DIM. “Y” DIM. FLUE DIA. GASKET PART #

OC2 5-1/2” 3-5/8” 28-3/8” 5” 14121/330073

OC5 6-1/2” 4-3/4” 31-7/16” 6” 14131/330005

OH2 5-1/2” 3/5/8” 28-3/8” 5” 14121/330073

OH3 6-1/2” 4-9/16” 32-3/16” 6” 14131/330005

OH5 6-1/2” 4-3/4” 33-1/16” 6” 14131/330005

OH11 6-1/2” 4-3/4” 35-1/4” 6” 14131/330005

OH16 7-1/2” 4-5/16” 41-3/8” 7” 14132/330006

OL2* 5-1/2” 3-5/8” 28-5/16” 5” 14121/330073

OL5* 6-1/2” 4-5/8” 34-15/16” 6” 14131/330005

OL11* 6-1/2” 4-1/2” 37-5/8” 6” 14131/330005

OL16* 7-1/2” 4-1/2” 39-1/8” 7” 14132/330006

OL20* 7-1/2” 4-1/2” 43-1/4” 7” 14132/330006

* FRONT FLUE MODELS ONLY

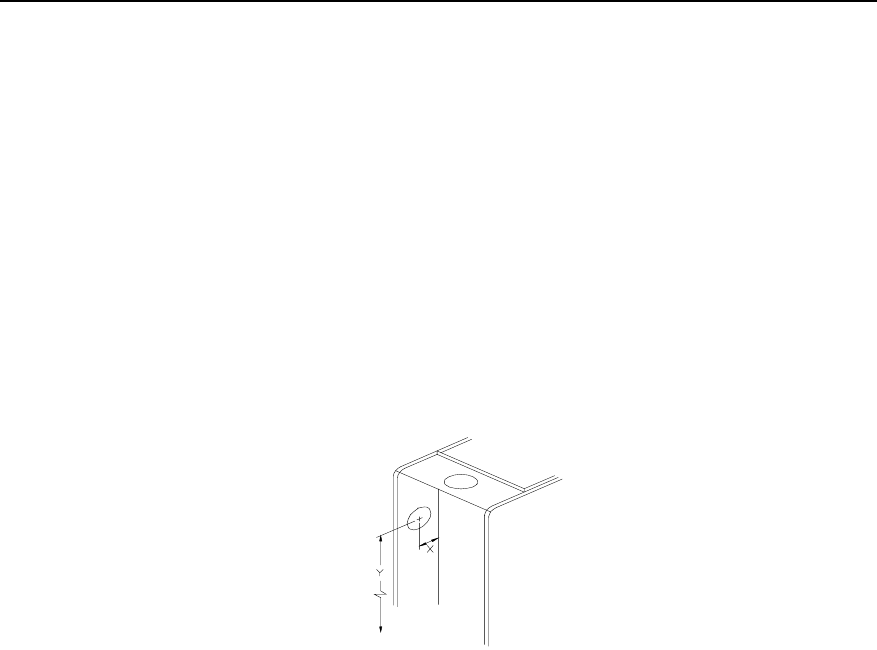

“X” DIMENSION IS MEASURED FROM SEPARATOR PANEL.

“Y” DIMENSION IS MEASURED FROM THE BLOWER PAN ON “H” MODELS AND FROM THE BASE ON

“L” AND “C” MODELS.

Fig 1: Recommended location for drilling hole to connect

vent pipe to the furnace through the left hand side casing.

A. DRAFT REGULATORS:

A draft regulator is supplied with the furnace and should be installed according to the regulator manufacturers

recommendations. With the burner operating, use a draft gauge to adjust the regulator to the proper setting. (refer to

the instructions enclosed with draft regulator to adjust to the proper setting). When the burner air supply and draft are

properly adjusted, the overfire draft should be a negative (-).01" to (-).02" WC, as measured at the 5/16" overfire air

tap (See Fig. T). This tap is provided in the upper burner mounting plate. To measure the flue draft, punch a small

hole in the vent connector pipe as close to the furnace as possible and always before the draft regulator.

B. DUCT WORK/AIR CONDITIONING:

If the furnace is used in connection with summer air conditioning (cooling), the furnace should be installed parallel

with or on the upstream side of the evaporator coil to avoid condensation in the furnace heat exchanger. If the

cooling unit is installed with a parallel flow arrangement, dampers or other means used to control flow of air should

be provided to prevent chilled air from entering the furnace. If such a damper is manually operated, it must be

equipped with a means to prevent operation of either unit, unless the damper is in the full heat or cool position.