NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

7

Union

Regulator

Fireplace or

Firebox Wall

Wall

Shut-Off

Key

3"

Manual

Shut-Off

Valve

Fireplace or

Firebox Wall

Sediment

Trap

Down

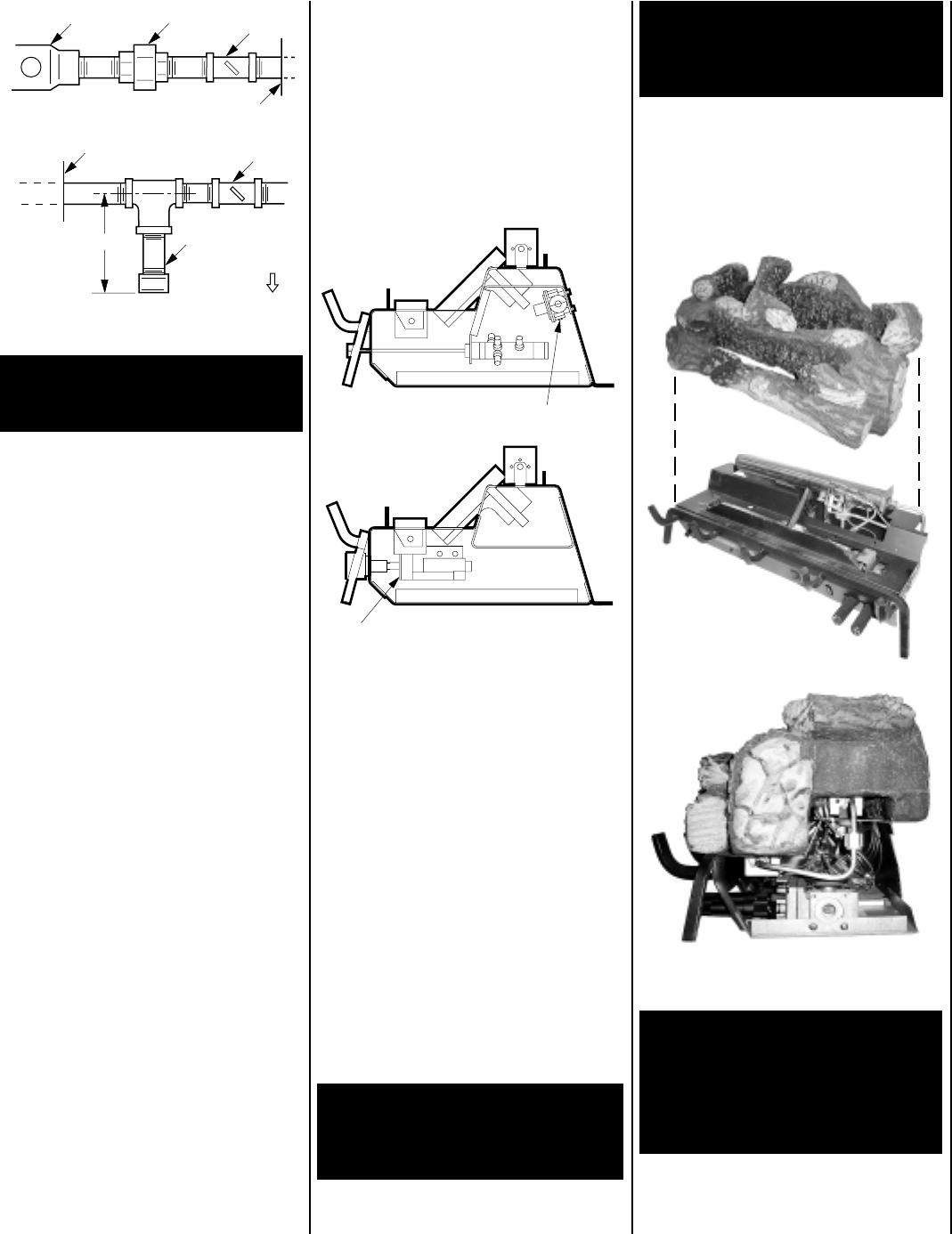

Each heater includes a unitized set of ceramic

fiber logs. The heater and logs are assembled

as shown in

Figure 11

. Handle these logs with

great care. The logs can be easily damaged, but

when handled properly they can provide years

of performance and enjoyment.

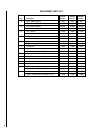

Manual Valve

Pressure Test Point

Millivolt Valve

Pressure Test Point

On Front Of Valve

Periodically verify proper positioning of all logs.

Figure 11

Millivolt Log Set

Shown, Manual

Similar

Figure 9

WARNING: CONNECTING DIRECTLY TO

AN UNREGULATED PROPANE TANK MAY

CAUSE AN EXPLOSION.

The heater gas inlet connection is 3/8" NPT at

the regulator, located on the right side facing

the heater. If a left side connection is required,

the connection pipe may be piped under the

rear of the appliance to end at the left hand side

for connection to the inlet.

When tightening up the joint to the regulator

hold the regulator securely with a wrench to

prevent the regulator from moving.

Checking Gas Connections: Turn on gas sup-

ply and test for gas leaks using a gas leak test

solution (also referred to as bubble leak solu-

tion). NOTE: using a soapy water solution

(50% dish soap, 50% water) is an effective leak

test solution, but it is not recommended, be-

cause the soap residue that is left on the pipes/

fittings can result in corrosion over time.

A. Light the appliance (refer to the lighting

instructions label in the control compartment

or on pages 12 or 14).

B. Brush all joints and connections with the gas

leak test solution to check for leaks. If bubbles

are formed, or gas odor is detected, turn the

gas control knob (off/pilot/on) to the “OFF”

position. Either tighten or refasten the leaking

connection, then retest as described above.

C. When the gas lines are tested and leak free,

be sure to rinse off the leak testing solution.

D. Observe the individual tongues of flame on

the burner. Make sure all ports are open and

producing flame evenly across the burner. If

any ports are blocked, or partially blocked,

clean out the ports.

WARNING: DO NOT PLACE ANY LAVA

ROCK ON LOGS OR BURNERS. THIS MAY

CAUSE SOOTING. ONLY PLACE LAVA

ROCK ON FLOOR OF FIREPLACE.

WARNING: FAILURE TO POSITION THE

PARTS IN ACCORDANCE ITH THESE DIA-

GRAMS OR FAILURE TO USE ONLY PARTS

SPECIFICALLY APPROVED WITH THIS

HEATER MAY RESULT IN PROPERTY

DAMAGE OR PERSONAL INJURY.

Gas Pressure Check

The heater regulator controls the burner pres-

sure which should be checked at the pressure

test point (1/8" NPT plugged tap) located at

the bottom of the regulator (on manual mod-

els) or on the control valve itself (on Millivolt

models), identified A for the manifold side

and E for inlet pressure. Ensure operatilng

pressures are within the limits specified in

the techinical chart on page 10.

Figure 10

The pressure should be checked with the gas

heater burning and the control set to high (3).

The pressure regulator on manual models is

preset and locked to avoid tampering. If the

pressure is not as specified in the Technical

Details Chart on page 10, replace the regulator

with P/N 110351 for natural gas and P/N

110352 for propane (L.P.G.) heaters.

Replace the test point plug after pressure

measurement ensuring no gas leaks.

Step 3. Secure the log set within the firebox

using the screws and drilled holes discussed

in Step 2.

Step 4. Assembling the Logs

WARNING: DO NOT ADD EXTRA LOGS OR

ORNAMENTS SUCH AS PINE CONES, VER-

MICULITE OR ROCK WOOL. USING THESE

ADDED ITEMS CAN CAUSE SOOTING.