5

WWW.WEBER.COM

®

5

1

1

1

2

a

2

a

3

4

5

6

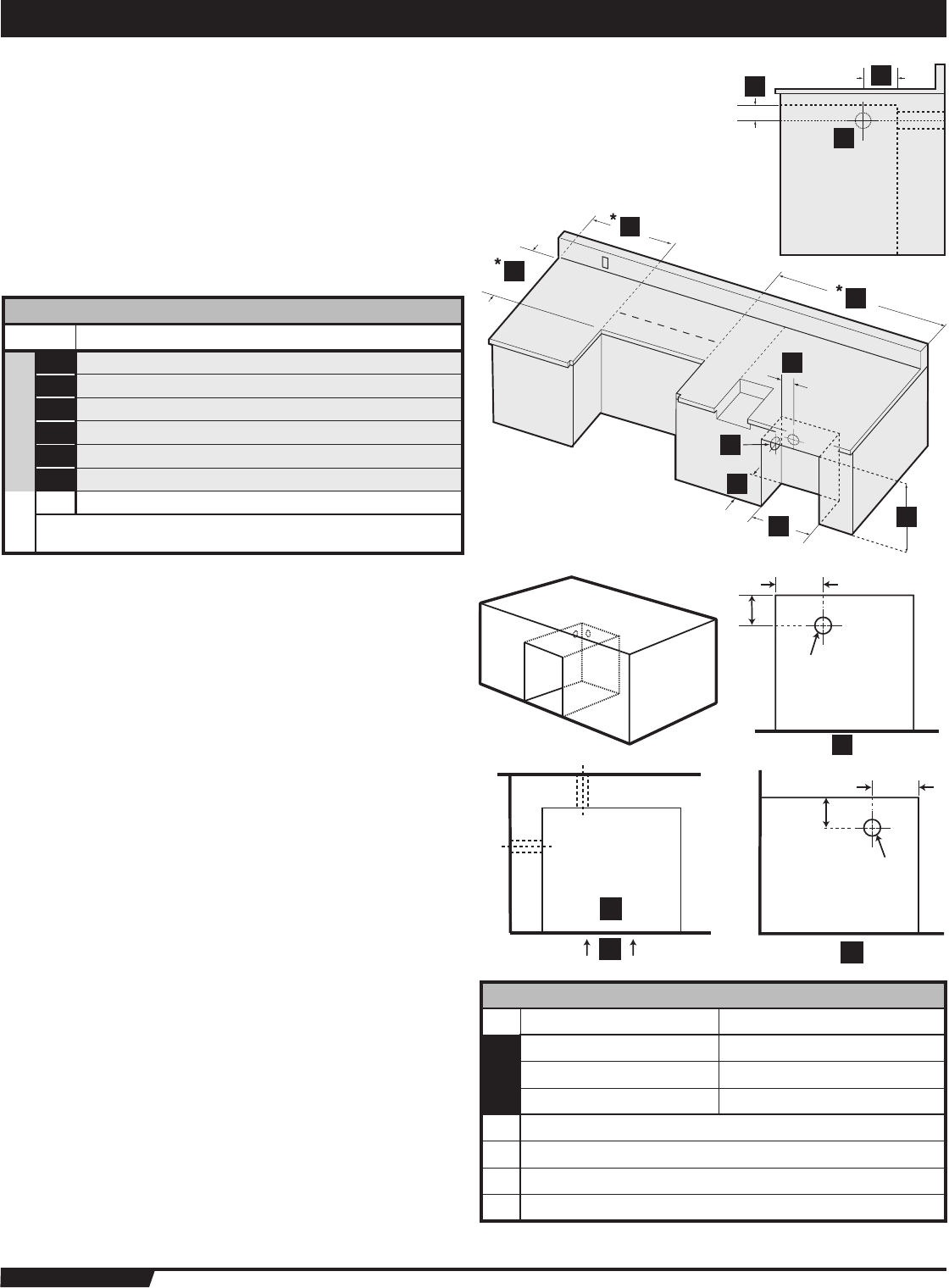

BUILT-IN GAS LINE LOCATIONS

GENERAL CONSTRUCTION DETAILS

• Summit

®

Built-In unit and all other accessory units should be on site before

construction begins.

• All dimensions have a tolerance of plus or minus (+/-)

1

/

4

inch (6.4mm).

BUILT-IN GAS LINE LOCATIONS

Area should be kept clear of sharp, jagged, or extremely abrasive surfaces to avoid

possible damage to gas supply lines. Exercise caution when pulling gas lines through

built-in structure.

A

C

B

1

3

2

A

B

C

C

LP TANK CABINET GAS LINE DIMENSIONS

Area should be kept clear of sharp, jagged, or extremely abrasive surfaces to avoid

possible damage to gas supply lines. Exercise caution when pulling gas lines through

built-in structure.

BUILT-IN CUTOUT DIMENSIONS

S-440, S-640

DIMENSIONS

1

24” (610 mm) minimum*

2

5” (127 mm)

3

2 1/2” (63.5 mm)

4

14” (355.6 mm)

5

20 3/4” (527.1 mm)

6

27 1/2” (698.5 mm)

a

Gas Inlet

* Clearance from any surface or structure is at least 24” (610mm)

from the back and sides of the grill or side burner.

GAS LINE DIMENSIONS

TANK CABINET TOLERANCES

1 5” (127 mm) +

1

/

4

˝ -

1

/

4

˝ (6.35mm)

2 2 1/2” (63.5 mm) +

1

/

4

˝ -

1

/

4

˝ (6.35mm)

3 2 3/4” (69.85 mm) +

1

/

4

˝ -

1

/

4

˝ (6.35mm)

A Front View

B Plan View

C Side View

D Front of LP Tank Cabinate Structure

ASSEMBLY