Pump Tanks Chapter 6: Appendix 25 of 36

Process Pump Curves and Specifications

A0548756

100

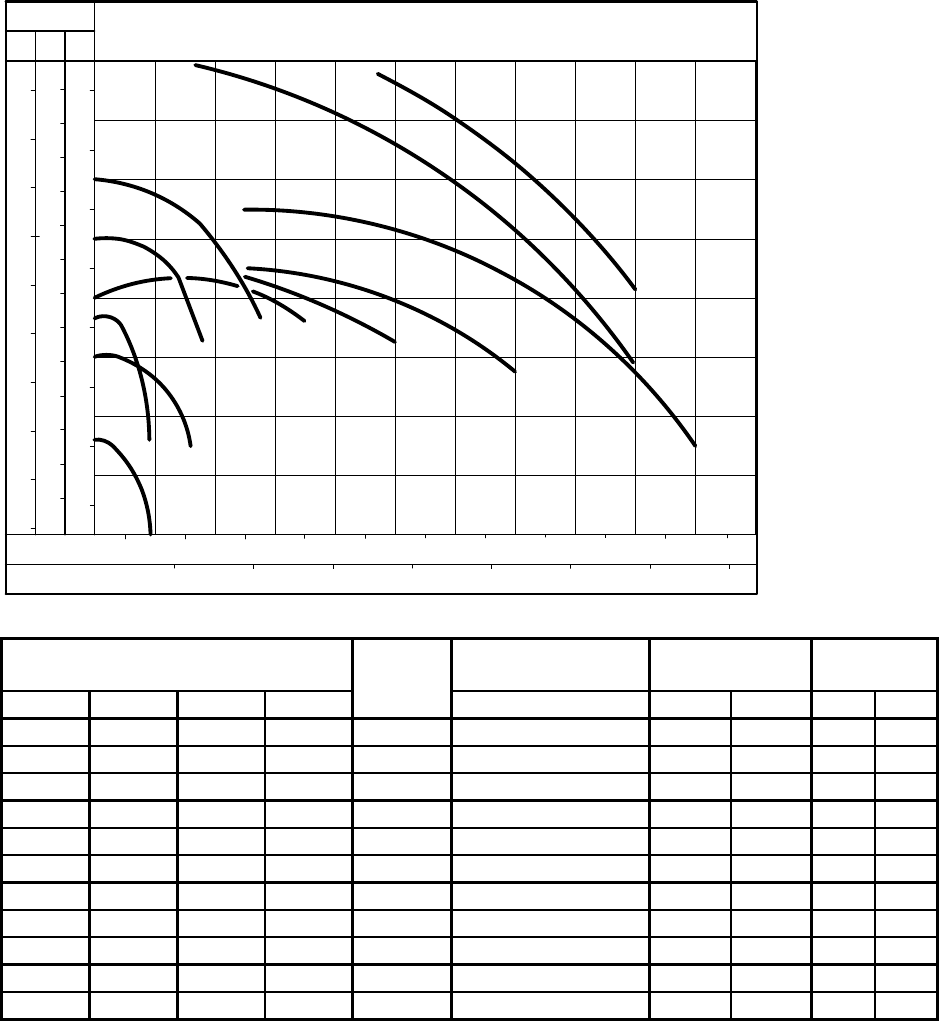

P1 PROCESS PUMP CURVES - 60 CYCLE

120

140

160

180

200

220

PSI

CM

KG/

2

FEET

TOTAL HEAD

PER MINUTE

LITERS

PER MINUTE

U.S. GALLONS

40

50

60

70

80

90

100

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

100 200 300 400 500 600 700 800 900 1000

500 1000 1500 2000 2500 3000 3500 4000

3 HP

5 HP

7 1/2 HP

10 HP

15 HP

20 HP

25 HP

30 HP

40 HP

50 HP

60 HP

Pump Information

Pump

Final discharge

trim size

ℵ

Pump ship

wt.

Trim ship

wt.

Model IMP. hp kW rpm inches lbs. kg lbs. kg

16 5.2” 3 2.24 3,500 2” NPT 95 44 25 12

50 6.0” 5 3.73 3,500 2½” flange 115 53 35 16

52 5.75” 7½ 5.59 3,500 3” flange 125 57 50 23

52 6.5” 10 7.46 3,500 3” flange 165 75 50 23

54F 6.5” 15 11.19 3,500 4” flange 180 82 75 35

55F 6.5” 20 14.92 3,500 4” flange 300 137 75 35

56F 6.3” 25 18.65 3,500 6” flange 310 141 95 44

57 6.4” 30 22.38 3,500 6” flange 400 182 95 44

57 6.87” 40 29.84 3,500 6” flange 465 212 120 55

63 7.5” 50 37.30 3,500 6” flange 710 323 120 55

63 8.2” 60 44.76 3,500 8” flange 730 332 165 75

ℵ Weld slip-on flange sent at discharge termination for flanged trim. 2” terminates at valve connection.