Cabinet Series Dehumidifying Dryer 51

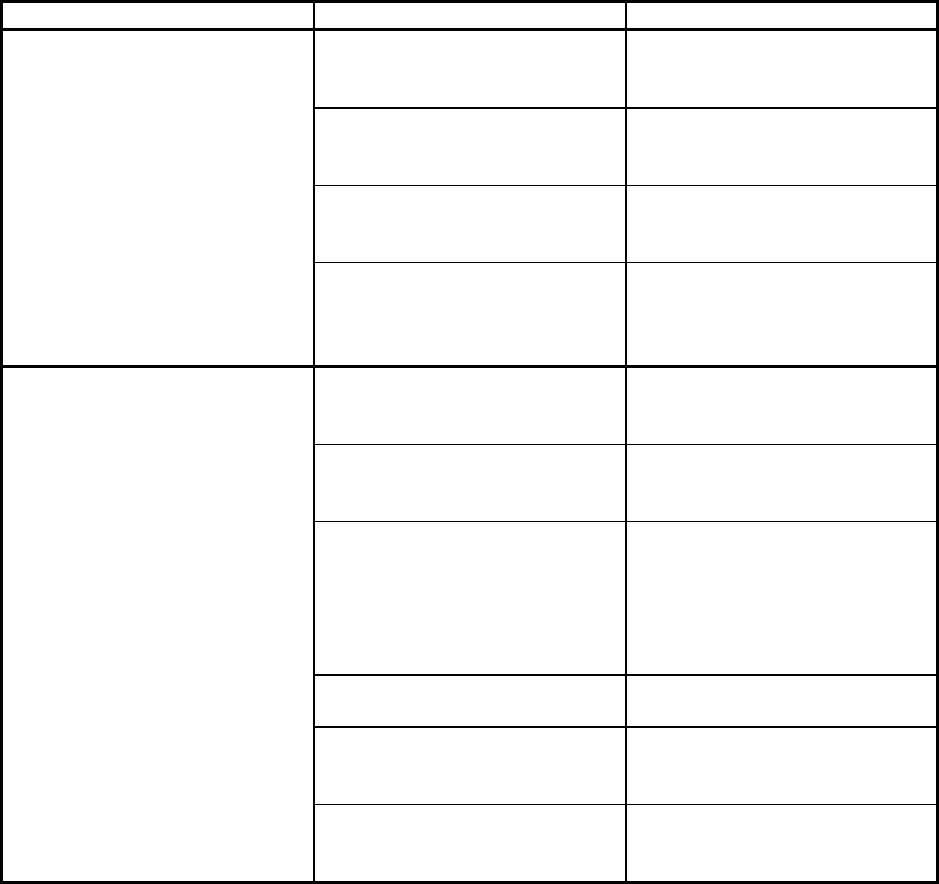

Problem Possible cause Corrective action

The internal mechanism is

not inserted properly into the

housing.

Properly insert the internal

mechanism into the housing.

The power supply is not

connected to its terminals

properly.

Properly connect the power

supply to the power supply

terminals.

No power is supplied, or the

supplied power is not within

the specified range.

Supply a voltage of 85 to 125

VAC to the power supply

terminals of the controller.

Nothing displays when the

controller is turned on.

Disconnect switch or Control

Power switch not set to ON.

Control Power fuse blown.

Check control power fuse for

continuity. Turn disconnect

switch and control power

switch ON.

Input polarity on thermo-

couple is wrong or

connection is wrong.

Properly wire the terminals.

No compensating lead wires

used for extension of the

thermocouple.

Use proper compensating

lead wires and terminals.

Thermocouple and controller

are connected by wires other

than proper lead wires.

Use a dedicated thermo-

couple connector. If a

connector is a metal different

from the thermocouple and

controller, a temperature

error may result.

Sensor is broken or short-

circuited.

Replace with a good sensor.

The controller is influenced

by noise or other induction.

Separate input wires as far

as possible from the origin of

the noise.

Process value is abnormal or

not obtained.

Celsius temperatures used

instead of Fahrenheit or vice

versa.

Setup mode level 2 display

d-U. S-V display shows

setting.

Determining Temperature Controller Errors or Sensor Errors

Using a Thermocouple

If the controller displays a temperature that is close to room temperature (70ºF/21ºC) when you short-

circuit controller input terminals, the controller is normal and the sensor is probably broken, short-

circuited, or incorrectly wired.

Using a Platinum Resistance Thermometer

If the controller displays a temperature of about 0.0°C (32ºF) when you insert a 100-ohm resistor between

terminals A and –B of the controller, and you short-circuit controller terminals +B and

–B, the controller is normal and the sensor is probably broken, short-circuited, or incorrectly wired.