7

Continued pilot outage preceded by higher than usual water

temperature is evidence of high limit switch operation. Contact

your dealer or servicer to determine the reason for operation.

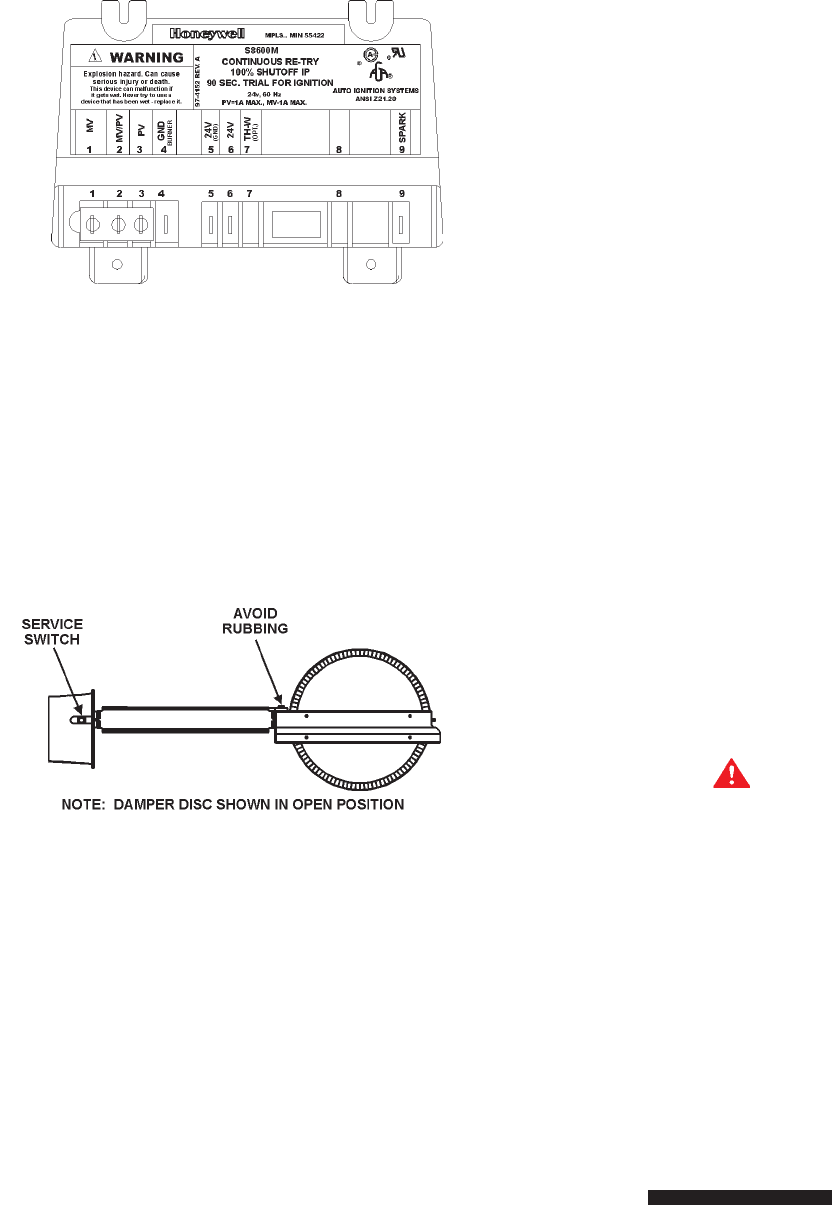

ELECTRONIC IGNITION CONTROL

Each heater is equipped with a Honeywell ignition module. The

solid state ignition control, fig. 4, ignites the pilot burner gas by

creating a spark at the pilot assembly. Pilot gas is ignited and

burns during each running cycle. The main burner and pilot

gases are cut off during the OFF cycle. Pilot gas ignition is

proven by the pilot sensor. Main burner ignition will not occur if

the pilot sensor does not first sense pilot ignition.

HONEYWELL IGNITION MODULE

S8600M Continuous Re-Try

FIGURE 4

AUTOMATIC FLUE DAMPER DEVICE

All units are equipped with an automatic flue damper that reduces

heat loss during the OFF cycles. The automatic flue damper

drive assembly is a field replaceable part and may be obtained

by contacting State Water Heaters.

Each automatic flue damper drive assembly is equipped with a

“Service Switch”, as shown in figure 5.

FIGURE 5

The “Service Switch” has 2 positions: AUTOMATIC OPERATION

and HOLD OPEN DAMPER. For normal operation the switch

should be in the AUTOMATIC OPERATION position.

If there is a problem with the damper the “Service Switch” can be

placed in the HOLD OPEN DAMPER position. When the switch

is placed in the HOLD OPEN DAMPER position the damper disc

will rotate to the open position and the heater may be used until

vent assembly is repaired or replaced. DO NOT turn the damper

disc manually; damage will occur to the drive assembly if operated

manually. Refer to TESTING DAMPER OPERATION section of

this manual for additional information.

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the

heater. Refer to the piping diagrams in this manual for electrical

hookup information and install in accordance with the latest

version of the

National Electric Code ANSI/NFPA No. 70. For

Canada refer to Canadian Code CSA C22.1.

Only all bronze circulators should be used with commercial

water heaters.

Although circulators are oiled and operated by the manufacturer

some circulators must be oiled again before operating. Please

refer to manufacturer’s instructions.

DISHWASHING MACHINE REQUIREMENT

These appliances meet the National Sanitation Foundation

Standard for sanitary installations when used with the following

leg kits, Part No’s. 6570-0 and 6570-7.

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water

flow pressures between 15 and 25 psi (103 Kpa and 173 Kpa).

Flow pressures above 25 psi (173 Kpa), or below 15 psi (103

Kpa), will result in improperly sanitized dishes. Where pressures

are high, a water pressure reducing or flow regulating control

valve should be used in 180°F (82°C) line to the dishwashing

machine, and should be adjusted to deliver water between these

limits.

The National Sanitation Foundation also recommends

circulation of 180°F (82°C) water. Where this is done, the

circulation should be very gentle so that it does not cause any

unnecessary turbulence inside the water heater. The circulation

should be just enough to provide 180°F (82°C) water at the point

of take-off to the dishwashing machine. Adjust flow by means of

the plug cock in the circulating line.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPLY, VENTING, GAS SUPPLY AND ELECTRICAL WORK

ARE REQUIRED.

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

UNCRATING

The heater is shipped with the flue damper already installed.

The wiring conduit runs from the thermostat to the damper drive

cover. Before turning unit on, check to make sure the wiring

conduit is securely plugged into damper drive.

LOCATING THE HEATER

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practicable, with adequate air supply and as

centralized with the piping system as possible.