12

NOTE: for Water Heaters in locations with high ambient temperatures

(above 100°F or 38°C) and/or insufcient dilution air, it is recommended that

CPVC or ABS pipe and ttings (MUST USE SUPPLIED VENT TERMINAL)

be used.

4. It is important that condensate not be allowed to buildup in the exhaust

vent pipe. To prevent this from happening the pipe should be installed with

a slight, 1/8" (3mm) per 5' (152 cm) of pipe maximum downward slope.

5. The vent system should be supported every 5' (152 cm) of vertical run

and every 3' (91cm) of horizontal run of vent pipe length.

NOTE: Stress levels in the pipe and ttings can be signicantly increased

by improper installation. If rigid pipe clamps are used to hold the pipe in

place, or if the pipe cannot move freely through a wall penetration, the

pipe may be directly stressed, or high thermal stresses may be formed

when the pipe heats up and expands. Install accordingly to minimize

such stresses.

VENT PIPE PREPARATION

1. INITIAL PREPARATION

A. Make sure the solvent cement you are planning to use is designed

for the specic application you are attempting.

B. Know the physical and chemical characteristics and limitations of

the PVC, PVC cellular core, ABS or CPVC piping materials that you

are about to use.

C. Know the reputation of your pipe and cement manufacturer and

their products.

D. Know your own qualifications or those of your contractor. The

solvent welding technique of joining PVC, PVC cellular core, ABS or

CPVC pipe is a specialized skill just as any other pipe fitting

technique.

E. Closely supervise the installation and inspect the nished job before

start-up.

F. Contact the manufacturer, supplier, or competent consulting agency

if you have any questions about the application or installation of

PVC, PVC cellular core, ABS or CPVC pipe.

G. Take the time and effort to do a professional job. Shortcuts will only

cause you problems and delays in start-up. The majority of failures

in these systems are the result of shortcuts and/or improper joining

techniques.

2. SELECTION OF MATERIALS

PRIMER

It is recommended that Tetrahydrofuran (THF) be used to prepare the surfaces

of pipe and ttings for solvent welding. Do not use water, rags, gasoline or

any other substitutes for cleaning PVC cellular core, ABS or CPVC surfaces.

A chemical cleaner such as MEK may be used.

CEMENT

The cement should be a bodied cement of approximately 500 to 1600

centipoise viscosity containing 10-20% (by weight) virgin PVC material

solvated with tetrahydrofuran (THF). Small quantities of dimethyl formamide

(DMF) may be included to act as a retarding agent to extend curing time.

Select the proper cement; Schedule 40 cement should be used for Schedule

40 pipe. Never use all-purpose cements, commercial glues and adhesives

or ABS cement to join PVC or CPVC pipe and ttings.

SAFETY PRECAUTION: PRIMERS AND CEMENTS ARE EXTREMELY

FLAMMABLE AND MUST NOT BE STORED OR USED NEAR HEAT OR

OPEN FLAME. ALSO, USE ONLY IN A WELL-VENTILATED AREA.

INSTALLATION OF VENT SYSTEM

WARNING

THE OPTIONAL INTAKE VENTING ARRANGEMENT AND THE

EXHAUST VENTING ARRANGEMENT MUST BE INSTALLED TO

RUN DIRECTLY TO THE OUTDOORS AND NOT IN ANY WAY BE

CONNECTED TO ANOTHER VENTING SYSTEM (I.E. FURNACE,

DRYERS OR SPACE HEATERS). IT IS CRUCIAL THAT THE VENTING

ARRANGEMENT BE KEPT SEPARATE FROM OTHER VENTING

SYSTEMS. IF THIS WARNING IS IGNORED, AND THE SYSTEM IS

VENTED INCORRECTLY, IT MAY CAUSE IMPROPER OPERATION,

FIRE, EXPLOSION, OR ASPHYXIATION.

1. Plan the route of the vent system from the vent termination to the planned

location of the appliance. Layout the total vent system to use the minimum

of vent pipe and elbows possible.

2. The installer may add up to a MAXIMUM OF FIFTY (50) EQUIVALENT

FEET (15.2 m) of pipe to the exhaust venting arrangement. This

addition of FIFTY (50) EQUIVALENT FEET (15.2 m) of pipe on both

the intake venting arrangement and exhaust venting arrangement must

include any 3" PVC elbows which equals (5) EQUIVALENT FEET (1.5

m) of pipe.

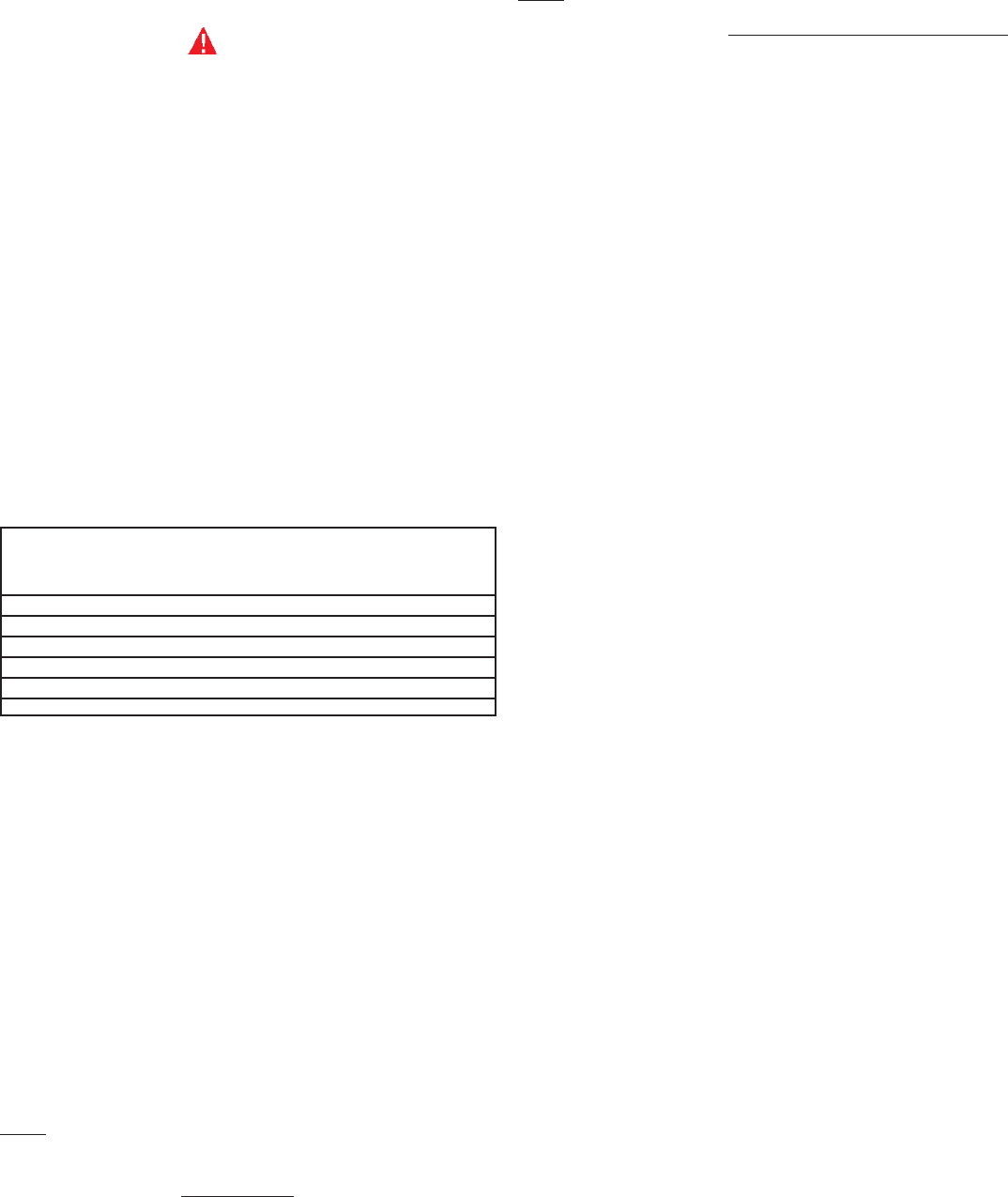

Table 2. VENT LENGTH TABLE

Number 3" 3" 4"

of 90° Minimum Maximum Maximum

Elbows Pipe (Ft./M.) Pipe (Ft./M.) Pipe (Ft./M.)

ONE (1) 7/2 45/13.7 115/35

TWO (2) 7/2 40/12.2 110/33.5

THREE (3) 7/2 35/10.7 105/32

FOUR (4) 7/2 30/9.1 100/30.5

FIVE (5) 7/2 --- 95/29

SIX (6) 7/2 --- 90/27.4

4" PVC may be used for a MAXIMUM intake of ONE HUNDRED TWENTY

(120) EQUIVALENT FEET (36.6m) and a MAXIMUM exhaust of ONE

HUNDRED TWENTY (120) EQUIVALENT FEET (36.6m). The maximum

number of 90° elbows with the 4" venting is six (6) on the intake and six

(6) on the exhaust. A 90° elbow is equal to ve (5) equivalent feet (1.5m)

of pipe. One (1) 90° elbow is equal to two (2) 45° elbows. Any venting

conguration using less than 50 equivalent feet should use 3" venting.

See Table 2.

The 3" venting terminals (provided) must be used with the

3" vent pipe. Two, approved 4" vent terminals (not provided) must be used

with 4" vent pipe. See replacement parts list for terminals.

IMPORTANT

When multiple units are direct vented through a wall (3" or 4" venting), all

intake vent terminals should be no lower than the highest exhaust vent

terminal.

NOTE: This unit can be vented using only PVC (Class 160, ASTM D-2241

Schedule 40, ASTM D-1785 ; or Cellular Core Schedule 40 DWV, ASTM

F-891) , Schedule 40 CPVC (ASTM F-411), or ABS (ASTM D-2661) pipe.

The ttings, other than the TERMINATIONS should be equivalent to PVC-

DWV ttings meeting ASTM D-2665 (Use CPVC ttings, ASTM F-438 for

CPVC pipe and ABS ttings, ASTM D-2661/3311 for ABS pipe. If CPVC or

ABS pipe and ttings are used, then the proper cement must be used for

all joints, including joining the pipe to the Termination (PVC Material). PVC

Materials should use ASTM D-2564 Grade Cement; CPVC Materials should

use ASTM F-493 Grade Cement and ; ABS Materials should use ASTM

D-2235 Grade Cement.