SM50 User Manual ◄ 13

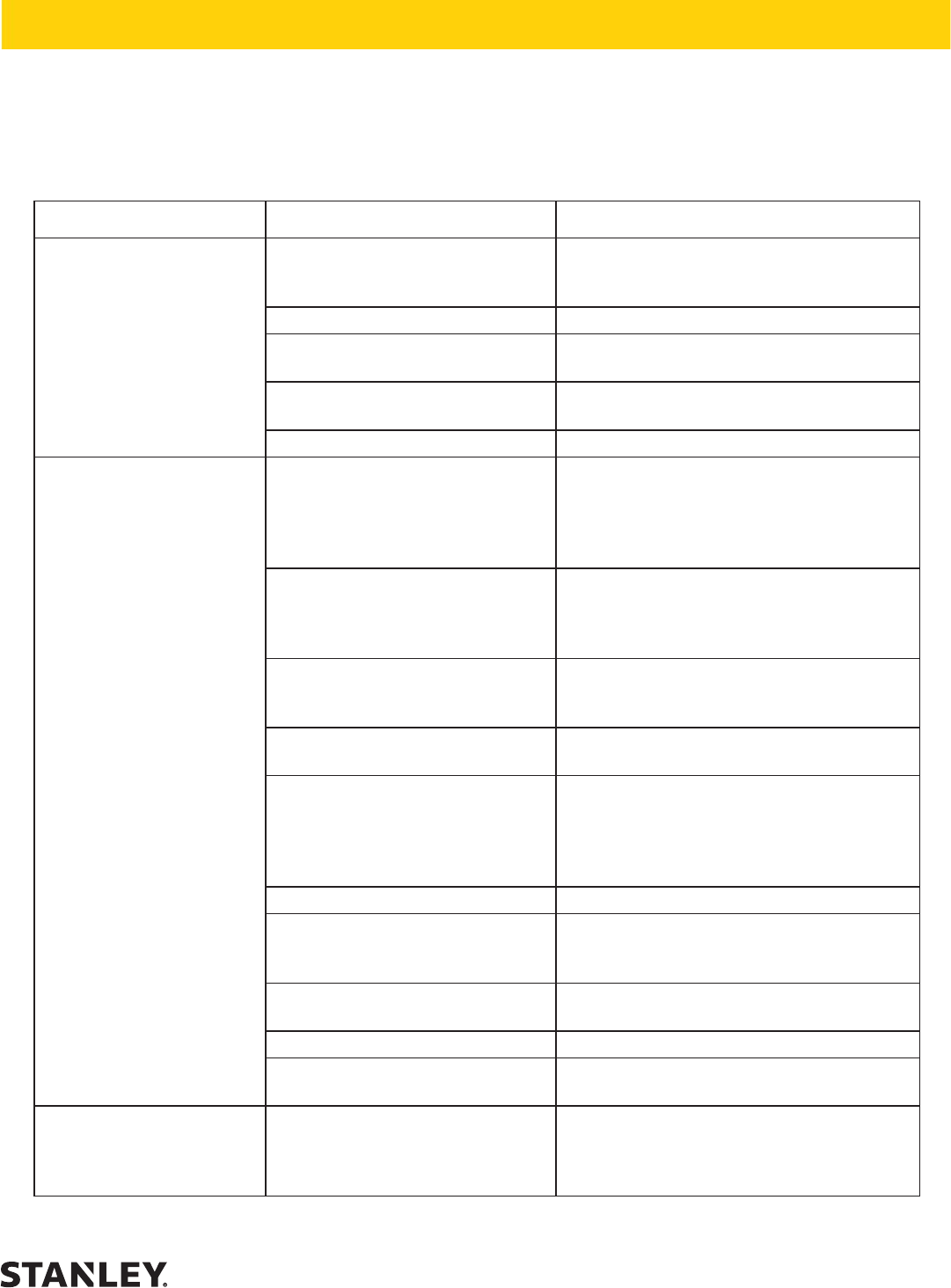

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation, always make sure the hydraulic power source is supplying the correct hydrau-

lic ow and pressure as listed in the table. Use a owmeter know to be accurate. Check the ow with the hydraulic

uid temperature at least 80 °F/27 °C.

PROBLEM CAUSE SOLUTION

Pump will not start. No hydraulic uid ow or pressure. Turn on power unit and check that 7–12

gpm/26–45 lpm at 1000-2000 psi/70–140

bar is available at the pump.

Defective couplers. Check the couplers. Replace if necessary.

Impeller jammed with debris. Clean the pumping chamber as described in

the Maintenance section in this manual.

Impeller rubbing against wear

plates.

Check and adjust the impeller clearance as

described in the Service Manual.

Defective hydraulic motor. Repair or replace motor.

Poor pump performance. Hydraulic ow reversed. Check that the hoses are correctly

connected to the pump motor ports. The

female coupler should be connected to the

“IN” port. The return uid must never ow

through a reversing valve.

Improper hydraulic uid ow. Check that 7–12 gpm/26-45 lpm at 1000–

2000 psi/70–140 bar is available at the trash

pump. A 20% decrease in ow can result in

a 50% decrease in pump performance.

Pump submersed in sediment. Lift the pump from the bottom of the hole or

chamber. Use a at support under the pump

if necessary.

Trash pump inlet restricted. Remove suction screen and thoroughly

clean. Reassemble.

Discharge hose kinked or

restricted.

Straighten the hose. If the hose must bend

at the top of the hole, use a piece of split

rigid conduit with large diameter of the

expanded hose. This keeps the hose from

kinking.

Discharge hose too small. Use a 3-inch diameter re hose.

Water lift too high. Lower the outlet end of the discharge hose.

Increase hydraulic ow (12 gpm/45 lpm

max).

Impeller worn or damaged. Check impeller for damage and excessive

wear. Replace if necessary.

Pump not matched to application Obtain higher capacity pump.

Hose used on suction side of

pump.

Remove. Use no plumbing on suction side

of pump.

Poor pump performance

with excessive wear.

Too many solids in the water.

Water speed out of the hose may

be too slow, therefore hose and

pump load up with solids.

Reduce solids content. Increase pump

speed.

TROUBLESHOOTING